Toyota Corolla (2004+). Manual - part 59

05-106

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

NOTICE:

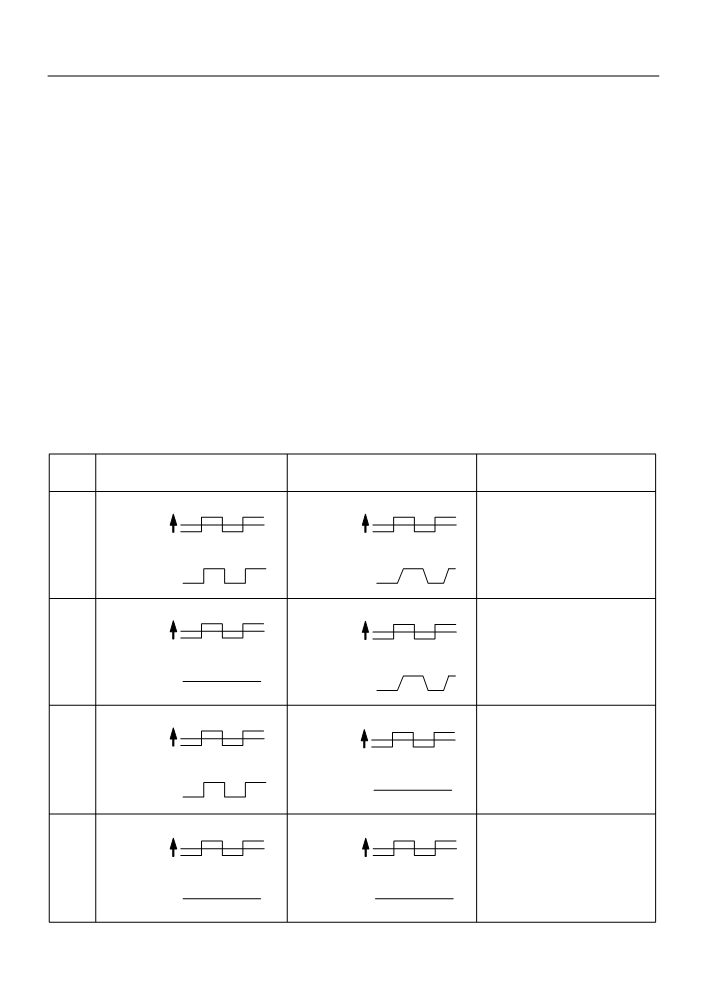

There is a delay of few seconds in the sensor 1 (front sensor) output, and there is about 20 seconds

delay at maximum in the sensor 2 (rear sensor).

Output voltage of heated oxygen

Output voltage of heated oxygen

Mainly suspect

sensor (sensor 1: front sensor)

sensor (sensor 2: rear sensor)

trouble area

Injection volume

Injection volume

+25 %

+25 %

-12.5 %

-12.5 %

Case 1

Output voltage

Output voltage

More than 0.5 V

More than 0.5 V

OK

OK

Less than 0.4 V

Less than 0.4 V

Injection volume

Injection volume

+25 %

+25 %

-12.5 %

-12.5 %

Sensor 1: front sensor

Output voltage

Output voltage

(sensor 1, heater, sensor 1

Case 2

circuit)

More than 0.5 V

No reaction

NG

OK

Less than 0.4 V

Injection volume

Injection volume

+25 %

+25 %

-12.5 %

Sensor 2: rear sensor

-12.5 %

Output voltage

Output voltage

(sensor 2, heater, sensor 2

Case 3

circuit)

More than 0.5 V

No reaction

NG

OK

Less than 0.4 V

Injection volume

Injection volume

+25 %

+25 %

Extremely rich or lean actual

-12.5 %

-12.5 %

air-fuel ratio

Case 4

Output voltage

Output voltage

(Injector, fuel pressure, gas

leakage in exhaust system,

No reaction

NG

No reaction

NG

etc.)

The following of A/F CONTROL procedure enables the technician to check and graph the voltage outputs

of both the heated oxygen sensors.

For displaying the graph indication, enter ”ACTIVE TEST / A/F CONTROL / USER DATA”, then select ”O2S

B1S1 and O2S B1S2” by pressing ”YES” button and push ”ENTER” button before pressing ”F4” button.

NOTICE:

If the vehicle is short of fuel, the air-fuel ratio becomes LEAN and heated oxygen sensor DTCs will

be recorded, and the MIL then comes on.

HINT:

F

If different DTCs related to different systems that have terminal E2 as the ground terminal are output

simultaneously, terminal E2 may be open.

F

Read freeze frame data using the hand−held tester or the OBD II scan tool. Freeze frame data records

the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determin-

ing whether the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio

was lean or rich, etc. at the time of the malfunction.

F

A high heated oxygen sensor (sensor 1) voltage (0.5 V or more) could be caused by a rich air fuel mix-

ture. Check for conditions that would cause the engine to run rich.

F

A low heated oxygen sensor (sensor 1) voltage (0.4 V or less) could be caused by a lean air fuel mix-

ture. Check for conditions that would cause the engine to run lean.

05-107

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

1

CHECK OTHER DTC OUTPUT(IN ADDITION TO HEATED OXYGEN SENSOR

DTCS)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Turn the ignition switch ON and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Select the item ”DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES”.

(d) Read the DTCs.

Result:

Display (DTC output)

Proceed to

”P0130, P2195 and/or P2196”

A

”P0130, P2195 and/or P2196” and other DTCs

B

HINT:

If any other codes besides P0130, P2195 and/or P2196 are output, perform the troubleshooting for those

DTCs first.

B

GO TO RELEVANT DTC CHART

(See page 05-35)

A

2

READ VALUE OF HAND-HELD TESTER OR OBD II SCAN TOOL(OUTPUT

VOLTAGE OF HEATED OXYGEN SENSOR)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Start the engine and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Select the item ”DIAGNOSIS / ENHANCED OBD II / DATA LIST / ALL / O2S B1S1”.

(d) Warm up the heated oxygen sensor with the engine speed at 2,500 rpm for approximately 90 seconds.

(e) Read the output voltage of the heated oxygen sensor during idling.

Heated oxygen sensor output voltage:

Alternates repeatedly between less than 0.4 V and more than 0.5 V (See the following table).

A85076

OK Go to step 9

NG

05-108

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

3

INSPECT HEATED OXYGEN SENSOR(HEATER RESISTANCE)

(a) Disconnect the H5 heated oxygen sensor connector.

Component Side:

Heated Oxygen Sensor

(b) Measure the resistance between the terminals of the

H5

HT

heated oxygen sensor connector.

Bank 1,

+B

Sensor 1

Standard:

Tester Connection

Specified Condition

HT (H5-1) - +B (H5-2)

5 to 10 W at 20 _C (68 _F)

HT (H5-1) - E1 (H5-4)

10 kW or higher

E1

OX

(c)

Reconnect the heated oxygen sensor connector.

Front View

A79112

NG REPLACE HEATED OXYGEN SENSOR

OK

4

INSPECT EFI RELAY

(a) Remove the EFI relay from the engine room R/B.

(b) Check for continuity in the EFI relay.

Standard:

Tester Connection

Specified Condition

1 - 2

Continuity

No continuity

3 - 5

Continuity

(Apply battery voltage to terminals 1 and 2)

(c)

Reinstall the EFI relay.

E34090

NG REPLACE EFI RELAY

OK

05-109

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

5

CHECK HARNESS AND CONNECTOR(HEATED OXYGEN SENSOR - ECM)

Wire Harness Side:

(a) Disconnect the H5 heated oxygen sensor connector.

H5

Heated Oxygen Sensor Connector

(b) Disconnect the E4 ECM connector.

Bank 1 Sensor 1

(c)

Check the resistance between the wire harness side con-

nectors.

HT

Standard (Check for open):

Tester Connection

Specified Condition

OX

HT (H5-1) - HT1A (E4-4)

Below 1 W

OX (H5-3) - OX1A (E4-23)

Front View

A79114

Standard (Check for short):

Tester Connection

Specified Condition

HT (H5-1) or HT1A (E4-4) - Body ground

10 kW or higher

OX (H5-3) or OX1A (E4-23) - Body ground

E4

(d) Reconnect the ECM connector.

(e) Reconnect the heated oxygen sensor connector.

HT1A

OX1A

ECM Connector

A55007

Reference (Bank 1 Sensor 1 System Drawing)

ECM

EFI Relay

Heated Oxygen Sensor

From

EFI Fuse

Heater

HT1A

Battery

Sensor

OX1A

From

Duty

Terminal 6 of

Control

Ignition Switch

Ground Ground

A82244

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

05-110

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

6

CHECK AIR INDUCTION SYSTEM

(a) Check the air induction system for vacuum leaks.

NG REPAIR OR REPLACE AIR INDUCTION SYSTEM

OK

7

CHECK FUEL PRESSURE (See page 11-5)

(a) Check the fuel pressure (high or low pressure).

NG REPAIR OR REPLACE FUEL SYSTEM

OK

8

INSPECT FUEL INJECTOR ASSY(INJECTION AND VOLUME) (See page 11-7)

NG REPLACE FUEL INJECTOR ASSY

OK

REPLACE HEATED OXYGEN SENSOR

9

PERFORM CONFIRMATION DRIVING PATTERN

HINT:

Clear all DTCs prior to performing the confirmation driving pattern.

GO

10

READ OUTPUT DTC(HEATED OXYGEN SENSOR DTCS ARE OUTPUT AGAIN)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Turn the ignition switch ON and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Read the DTC using the hand-held tester or the OBD II scan tool.

Result:

Display (DTC output)

Proceed to

”P0130, P2195 and/or P2196”

A

”P0130, P2195 and/or P2196” are not output

B

B

CHECK FOR INTERMITTENT PROBLEMS

(See page 05-41)

A

REPLACE HEATED OXYGEN SENSOR

05-111

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05DIK-01

DTC

P0133

OXYGEN SENSOR CIRCUIT SLOW

RESPONSE (BANK 1 SENSOR 1)

CIRCUIT DESCRIPTION

Refer to DTC P0130 on page 05-101.

DTC No.

DTC Detection Condition

Trouble Area

F Open or short in heated oxygen sensor (bank 1 sensor 1)

After engine has been warmed up, if response time that heated

circuit

oxygen sensor’s output voltage reaches from RICH to LEAN.

F Heated oxygen sensor (bank 1 sensor 1)

or from LEAN to RICH, is 0.6 second or more during idling.

F Heated oxygen sensor heater (bank 1 sensor 1)

(2 trip detection logic)

F EFI relay

P0133

F Air induction system

F Fuel pressure

If response time of heated oxygen sensor’s output voltage in

F Injector

one RICH-LEAN cycle is 6 seconds or more during idling. (2

F ECM

trip detection logic)

F

HINT:

Sensor 1 refers to the sensor closest to the engine assembly.

MONITOR DESCRIPTION

Slow slope condition:

Rich to Lean time

Lean to Rich time

Rich

0.55

0.45

0.40

Lean

Lean to Rich / Rich to Lean time definition

Time

A79137

The engine control module (ECM) uses the heated oxygen sensor information to regulate the air-fuel ratio

close to a stoichiometric ratio. This maximizes the catalytic converter’s ability to purify the exhaust gases.

The sensor detects oxygen levels in the exhaust gas and sends this signal to the ECM.

The inner surface of the sensor element is exposed to the outside air. The outer surface of the sensor ele-

ment is exposed to the exhaust gas. The sensor element is made of the platinum coated zirconia and in-

cludes an integrated heating element. The heated oxygen sensor has the characteristic whereby its output

voltage change suddenly in the vicinity of the stoichiometric air-fuel ratio. The heated oxygen sensor gener-

ates waveform of a voltage between 0 V and 1 V in response to the oxygen concentration in exhaust gas.

When the output voltage of the heated oxygen sensor is 0.55 V or more, the ECM judges that the air-fuel

ratio is RICH. When it is 0.40 V or less, the ECM judges that the air-fuel ratio is LEAN.

The ECM monitors the response feature of the heated oxygen sensor. If the response time of the sensor

output status change from RICH to LEAN or vice versa becomes longer, the ECM interprets this as a mal-

function in the heated oxygen sensor and sets a DTC.

05-112

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

Frequency condition:

One Cycle

Rich side frequency

O2 Sensor Voltage

0.45V

Lean side frequency

A84946

MONITOR STRATEGY

Related DTCs

P0133

Front heated oxygen sensor response monitor

Main sensors

Front heated oxygen sensor

Required sensors/components

Related sensors

Crank shaft position sensor, vehicle speed sensor, mass air flow sensor

Frequency of operation

Once per drive cycles

Duration

Within 60 seconds

MIL operation

2 driving cycles

Sequence of operation

None

TYPICAL ENABLING CONDITION

Specification

Item

Minimum

Maximum

The monitor will run whenever the follow-

See ”List of Disable a Monitor” (On page 05-25)

ing DTCs are not present

Frequency idle condition:

There is a history that the following condition (a) and (b) were met for 20seconds

(a) Vehicle speed

25 mph (40 km/h)

-

(b) Engine speed

900 rpm

-

Time after engine start

120 seconds

-

Idle

ON

Vehicle speed

-

3 mph (5 km/h)

Fuel system status

Closed loop

Engine coolant temperature

40_C (104_F)

-

Frequency cruise condition:

There is a history that the following condition (a) and (b) were met for 20seconds

(a) Vehicle speed

25 mph (40 km/h)

-

(b) Engine speed

900 rpm

-

Intake air amount

5 g/s

14.5 g/s

Time after engine start

120 sec

-

Idle

OFF

Fuel system status

Closed loop

05-113

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

Engine speed

1,000 rpm

3,500 rpm

Engine coolant temperature

70_C (104_F)

-

Slow slope condition:

There is a history that the following condition (a) and (b) were met for 20seconds

(a) Vehicle speed

25 mph (40 km/h)

-

(b) Engine speed

900 rpm

-

Time after engine start

120 seconds

-

Idle

ON

Vehicle speed

-

3 mph (5 km/h)

Fuel system status

Closed loop

Engine coolant temperature

40_C (104_F)

-

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

Frequency idle condition

w/ AT: 6 sec or more

Time required by the voltage output to change in one cycle

w/ MT: 5.5 sec or more

Frequency cruise condition

Time required by the voltage output to change in one cycle

a specific time or more

Slow slope condition

Time that output voltage of front heated oxygen sensor in-

0.6 seconds or more

crease from 0.4V to 0.55V and drops from 0.55V to 0.4V

COMPONENT OPERATING RANGE

Parameter

Standard Value

Voltage output of the front heated oxygen sensor fluctuates between 0.40 V and 0.5 V in an instant.

WIRING DIAGRAM

Refer to DTC P0130 on page 05-101.

05-114

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

INSPECTION PROCEDURE

HINT:

Hand-held tester only:

Narrowing down the trouble area is possible by performing ”A/F CONTROL” ACTIVE TEST (heated oxygen

sensor or other trouble areas can be distinguished). Perform ACTIVE TEST using hand-held tester (A/F

CONTROL).

(a) Perform ACTIVE TEST using the hand-held tester (A/F CONTROL).

HINT:

”A/F CONTROL” is the ACTIVE TEST which changes the injection volume to -12.5 % or +25 %.

(1)

Connect the hand-held tester to the DLC3 on the vehicle.

(2)

Turn the ignition switch ON.

(3)

Warm up the engine by running the engine speed at 2,500 rpm for approximately 90 seconds.

(4)

Select the item ”DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / A/F CONTROL”.

(5)

Perform ”A/F CONTROL” with the engine in an idle condition (press the right or left button).

Result:

Heated oxygen sensor reacts in accordance with increase and decrease of injection volume

+25 % rich output: More than 0.5 V,

-12.5 % lean output: Less than 0.4 V

NOTICE:

There is a delay of few seconds in the sensor 1 (front sensor) output, and there is about 20 seconds

delay at maximum in the sensor 2 (rear sensor)

Output voltage of heated oxygen

Output voltage of heated oxygen

Mainly suspect

sensor (sensor 1: front sensor)

sensor (sensor 2: rear sensor)

trouble area

Injection volume

Injection volume

+25 %

+25 %

-12.5 %

-12.5 %

Output voltage

Output voltage

Case 1

More than 0.5 V

More than 0.5 V

OK

OK

Less than 0.4V

Less than 0.4V

Injection volume

Injection volume

+25 %

+25 %

-12.5 %

-12.5 %

Sensor 1: front sensor

(sensor 1, heater, sensor 1

Case 2

Output voltage

Output voltage

circuit)

More than 0.5 V

No reaction

NG

OK

Less than 0.4V

Injection volume

Injection volume

+25 %

+25 %

-12.5 %

-12.5 %

Sensor 2: rear sensor

Output voltage

Output voltage

(sensor 2, heater, sensor 2

Case 3

circuit)

More than 0.5 V

OK

No reaction

NG

Less than 0.4V

Injection volume

Injection volume

Extremely rich or lean actual

+25 %

+25 %

-12.5 %

-12.5 %

air-fuel ratio

Case 4

(Injector, fuel pressure, gas

Output voltage

Output voltage

leakage in exhaust system,

No reaction

NG

No reaction

NG

etc.)

05-115

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

The following of A/F CONTROL procedure enables the technician to check and graph the voltage outputs

of both the heated oxygen sensors.

For displaying the graph indication, enter ”ACTIVE TEST / A/F CONTROL / USER DATA”, then select ”O2S

B1S1 and O2S B1S2” by pressing ”YES” button and push ”ENTER” button before pressing ”F4” button.

NOTICE:

If the vehicle is short of fuel, the air-fuel ratio becomes LEAN and DTC P0133 will be recorded, and

the MIL then comes on.

HINT:

F

If different DTCs related to different systems that have terminal E2 as the ground terminal are output

simultaneously, terminal E2 may be open.

F

Read freeze frame data using the hand−held tester or the OBD II scan tool. Freeze frame data records

the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determin-

ing whether the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio

was lean or rich, etc. at the time of the malfunction.

F

A high heated oxygen sensor (sensor 1) voltage (0.5 V or more) could be caused by a rich air fuel mix-

ture. Check for conditions that would cause the engine to run rich.

F

A low heated oxygen sensor (sensor 1) voltage (0.4 V or less) could be caused by a lean air fuel mix-

ture. Check for conditions that would cause the engine to run lean.

1

CHECK OTHER DTC OUTPUT(IN ADDITION TO DTC P0133)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Turn the ignition switch ON and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Read the DTCs using the hand-held tester or the OBD II scan tool.

Result:

Display (DTC output)

Proceed to

P0133

A

P0133 and other DTCs

B

HINT:

If any other codes besides P0133 are output, perform the troubleshooting for those DTCs first.

B

GO TO RELEVANT DTC CHART

(See page 05-35)

A

05-116

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

2

READ VALUE OF HAND-HELD TESTER OR OBD II SCAN TOOL(HEATED

OXYGEN SENSOR DURING IDLING)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Start the engine and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Select the item ”DIAGNOSIS / ENHANCED OBD II / DATA LIST / ALL / O2S B1S1”.

(d) Warm up the heated oxygen sensor with the engine speed at 2,500 rpm for approximately 90 seconds.

(e) Read the output voltage of the heated oxygen sensor during idling.

Heated oxygen sensor output voltage:

Alternates between less than 0.35 V and more than 0.45 V, and period of ”t” must exist less than

0.6 sec. (See the following table).

0.45V

0.35V

A85082

OK Go to step 9

NG

3

INSPECT HEATED OXYGEN SENSOR(HEATER RESISTANCE)

(a) Disconnect the H5 heated oxygen sensor connector.

Component Side:

Heated Oxygen Sensor

(b) Measure the resistance between the terminals of the

H5

+B

heated oxygen sensor connector.

HT

Bank 1,

Standard:

Sensor 1

Tester Connection

Specified Condition

HT (H5-1) - +B (H5-2)

5 to 10 W at 20 _C (68 _F)

HT (H5-1) - E1 (H5-4)

10 kW or higher

E1

OX

(c)

Reconnect the heated oxygen sensor connector.

Front View

A79112

NG REPLACE HEATED OXYGEN SENSOR

OK

05-117

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

4

INSPECT EFI RELAY

(a) Remove the EFI relay from the engine room R/B.

(b) Check for continuity in the EFI relay.

Standard:

Tester Connection

Specified Condition

1 - 2

Continuity

No continuity

3 - 5

Continuity

(Apply battery voltage to terminals 1 and 2)

(c)

Reinstall the EFI relay.

E34090

NG REPLACE EFI RELAY

OK

05-118

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

5

CHECK HARNESS AND CONNECTOR(HEATED OXYGEN SENSOR - ECM)

Wire Harness Side:

(a) Disconnect the H5 heated oxygen sensor connector.

H5

Heated Oxygen Sensor Connector

(b) Disconnect the E4 ECM connector.

(c)

Check the resistance between the wire harness side con-

Bank 1 Sensor 1

nectors.

HT

Standard (Check for open):

Tester Connection

Specified Condition

OX

HT (H5-1) - HT1A (E4-4)

Below 1 W

OX (H5-3) - OX1A (E4-23)

Front View

A79114

Standard (Check for short):

Tester Connection

Specified Condition

HT (H5-1) or HT1A (E4-4) - Body ground

10 kW or higher

OX (H5-3) or OX1A (E4-23) - Body ground

E4

(d) Reconnect the ECM connector.

(e) Reconnect the heated oxygen sensor connector.

HT1A

OX1A

ECM Connector

A55007

Reference (Bank 1 Sensor 1 System Drawing):

ECM

EFI Relay

Heated Oxygen Sensor

From

EFI Fuse

Heater

HT1A

Battery

Sensor

OX1A

From

Duty

Terminal 6 of

Control

Ignition Switch

Ground Ground

A82244

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

05-119

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

6

CHECK AIR INDUCTION SYSTEM

(a) Check the air induction system for vacuum leaks.

NG REPAIR OR REPLACE AIR INDUCTION SYSTEM

OK

7

CHECK FUEL PRESSURE (See page 11-5)

(a) Check the fuel pressure (high or low pressure).

NG REPAIR OR REPLACE FUEL SYSTEM

OK

8

INSPECT FUEL INJECTOR ASSY(INJECTION AND VOLUME) (See page 11-7)

NG REPLACE FUEL INJECTOR ASSY

OK

REPLACE HEATED OXYGEN SENSOR

9

PERFORM CONFIRMATION DRIVING PATTERN (See page 05-101)

HINT:

Clear all DTCs prior to performing the confirmation driving pattern.

GO

10

READ OUTPUT DTC(DTC P0133 IS OUTPUT AGAIN)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Turn the ignition switch ON and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Read the DTCs using the hand-held tester or the OBD II scan tool.

Result:

Display (DTC output)

Proceed to

P0133

A

No output

B

B

CHECK FOR INTERMITTENT PROBLEMS

(See page 05-41)

A

REPLACE HEATED OXYGEN SENSOR

05-120

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05CRQ-02

DTC

P0134

OXYGEN SENSOR CIRCUIT NO ACTIVITY

DETECTED (BANK 1 SENSOR 1)

CIRCUIT DESCRIPTION

Refer to DTC P0130 on page 05-101.

DTC No.

DTC Detecting Condition

Trouble Area

F Open or short in heated oxygen sensor (bank 1 sensor 1)

circuit

After engine is warmed up, heated oxygen sensor (bank 1

F Heated oxygen sensor (bank 1 sensor 1)

sensor 1) output does not indicate RICH (greater than 0.45 V)

F Heated oxygen sensor heater (bank 1 sensor 1)

even once when conditions (a), (b), (c), (d) and (e) continue for

F EFI relay

more than 65 seconds (1 trip detection logic) :

F Air induction system

(a) Engine speed: 1,400 rpm or more

P0134

F Fuel pressure

(b) Vehicle speed: 24.8 mph (40 km/h) or more

F PCV hose connection

(c) Throttle valve is not fully closed

F PCV valve and hose

(d) 180 seconds or more after starting engine

F Injector

(e) Engine coolant temperature is more than 40 _C (104 _F)

F Gas leakage in exhaust system

F PCV piping

F ECM

HINT:

After confirming DTC P0134, check the output voltage of the heated oxygen sensor (bank 1 sensor 1) in the

”DIAGNOSIS / ENHANCED OBD II / DATA LIST / ALL” using the hand−held tester or the OBD II scan tool.

If the output voltage of the heated oxygen sensor is always less than 0.1 V, the sensor circuit may be open

or short.

MONITOR DESCRIPTION

The ECM uses the heated oxygen sensor to optimize the air-fuel mixture in the closed-loop fuel control.

This control helps decrease exhaust emissions by providing the catalyst with a nearly stoichiometric mixture.

The sensor detects the oxygen level in the exhaust gas and the ECM uses this data to control the air-fuel

ratio. The sensor output voltage ranges from 0 V to 1 V. If the signal voltage is less than 0.4 V, the air-fuel

ratio is LEAN. If the signal voltage is more than 0.5 V, the air-fuel ratio is RICH. If the sensor does not indicate

RICH even once despite the conditions for the closed-loop fuel control being met and a specified time period

has passed, the ECM will conclude that the closed-loop fuel control is malfunctioning. The ECM will illumi-

nate the MIL and a DTC is set.

MONITOR STRATEGY

Related DTCs

P0134

Excessive time to enter closed loop

Main sensors

Front heated oxygen sensor

Required sensors/components

Crank shaft position sensor, engine coolant temperature sensor, vehicle

Related sensors

speed sensor

Frequency of operation

Once per drive cycles

Duration

65 seconds

MIL operation

1 driving cycles

Sequence of operation

None