Toyota Corolla (2004+). Manual - part 58

05-91

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

3

CHECK HARNESS AND CONNECTOR(ECM - THROTTLE POSITION SENSOR)

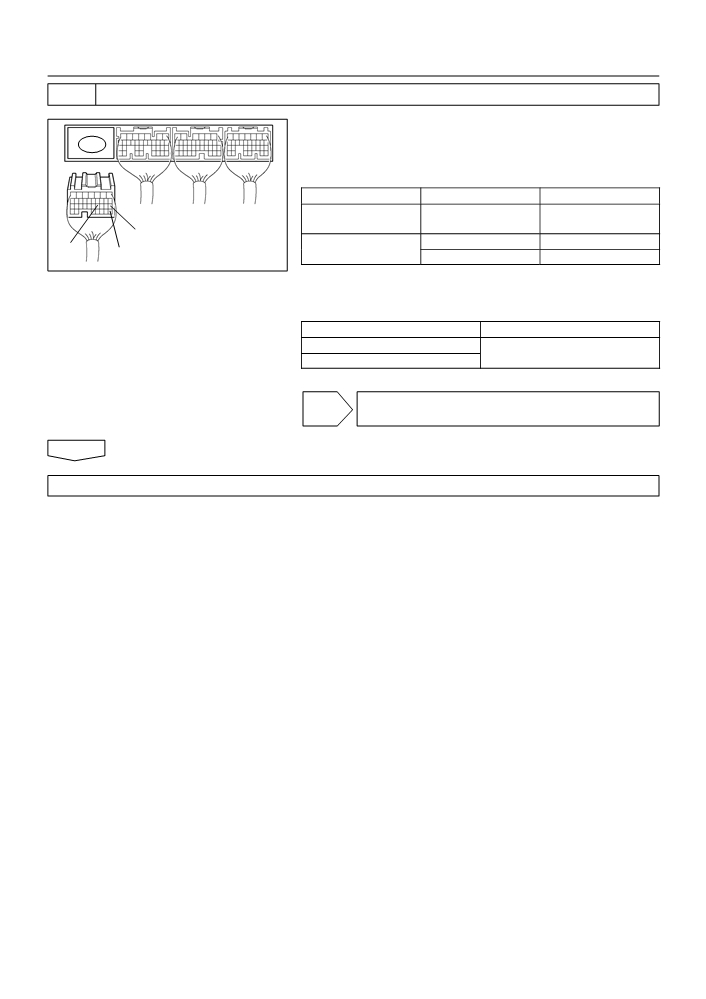

(a) Disconnect the E3 ECM connector.

(b) Measure the resistance between the terminals of the E3

E3

ECM connector.

Standard:

Tester Connection

Throttle Valve

Specified Condition

VC (E3-18)

2.5 to 5.9 kW

- E2 (E3-28)

VC

VTA(E3-21)

Fully closed

0.2 to 5.7 kW

VTA

E2

– E2 (E3-28)

ECM Connector

Fully open

2.0 to 10.2 kW

A65159

(c)

Check the resistance between the terminals of the E3

ECM connector.

Standard (Check for short):

Tester Connection

Specified Condition

VC (E3-18) - Body ground

10 kW or higher

VTA (E3-28) - Body ground

(d) Reconnect the ECM connector.

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

REPLACE ECM (See page 10-11 )

4

INSPECT THROTTLE POSITION SENSOR

(a) Disconnect the T1 throttle position sensor connector.

Component Side:

Throttle Position Sensor

(b) Measure the resistance between the terminals of the

T1

throttle position sensor.

Standard:

Tester Connection

Throttle Valve

Specified Condition

VC (T1-1) - E2 (T1-2)

2.5 to 5.9 kW

Fully closed

0.2 to 5.7 kW

VTA (T1-3) - E2 (T1-2)

Fully open

2.0 to 10.2 kW

VTA

E2

VC

Front View

A53154

(c)

Reconnect the throttle position sensor connector.

NG REPLACE THROTTLE POSITION SENSOR

OK

05-92

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

5

CHECK HARNESS AND CONNECTOR(ECM - THROTTLE POSITION SENSOR)

(a) Disconnect the E3 ECM connector.

E3

(b) Disconnect the T1 throttle position sensor connector.

(c)

Check the resistance between the wire harness side con-

nectors.

Standard (Check for open):

Tester Connection

Specified Condition

VC

VC (T1-1) - VC (E3-18)

VTA (T1-3) - VTA (E3-21)

Below 1 W

VTA

E2

ECM Connector

E2 (T1-2) - E2 (E3-28)

A65159

Standard (Check for short):

Wire Harness Side:

Tester Connection

Specified Condition

Throttle Position Sensor Connector

VC (T1-1) or VC (E3-18) - Body ground

T1

10 kW or higher

VTA (T1-3) or VTA (E3-21) - Body ground

(d) Reconnect the throttle position sensor connector.

(e) Reconnect the ECM connector.

1

2

3

VC E2

VTA

Front View

A84760

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

REPLACE ECM (See page 10-11)

OBD II scan tool (excluding hand-held tester):

1

INSPECT THROTTLE POSITION SENSOR

(a) Disconnect the T1 throttle position sensor connector.

Component Side:

Throttle Position Sensor

(b) Measure the resistance between the terminals of the

T1

throttle position sensor.

Standard:

Tester Connection

Throttle Valve

Specified Condition

VC (T1-1) - E2 (T1-2)

2.5 to 5.9 kW

Fully closed

0.2 to 5.7 kW

VTA (T1-3) - E2 (T1-2)

Fully open

2.0 to 10.2 kW

VTA

E2

VC

Front View

A53154

(c)

Reconnect the throttle position sensor connector.

NG REPLACE THROTTLE POSITION SENSOR

OK

05-93

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

2

CHECK HARNESS AND CONNECTOR(THROTTLE POSITION SENSOR - ECM)

(a) Disconnect the E3 ECM connector.

(b) Measure the resistance between the terminals of the E3

E3

ECM connector.

Standard:

Tester Connection

Throttle valve

Specified Condition

VC (E3-18)

2.5 to 5.9 kW

- E2 (E3-28)

VC

VTA(E3-21)

Fully closed

0.2 to 5.7 kW

VTA

E2

– E2 (E3-28)

ECM Connector

Fully open

2.0 to 10.2 kW

A65159

(c)

Check the resistance between the terminals of the E3

ECM connector.

Standard (Check for short):

Tester Connection

Specified Condition

VC (E3-18) - Body ground

10 kW or higher

VTA (E3-28) - Body ground

(d) Reconnect the ECM connector.

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

REPLACE ECM (See page 10-11)

05-94

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

052NE-14

DTC

P0121

THROTTLE/PEDAL POSITION

SENSOR/SWITCH ”A” CIRCUIT

RANGE/PERFORMANCE PROBLEM

HINT:

This is the purpose of the ”throttle position sensor”.

CIRCUIT DESCRIPTION

Refer to DTC P0120 on page 05-87.

DTC No.

DTC Detection Condition

Trouble Area

The following condition is met 4 times. After the vehicle speed

has exceeded 19 mph (30 km/h) once, the throttle position

P0121

F Throttle position sensor (built in throttle body)

sensor output value is out of normal range when the throttle

valve is closed at 0 km/h

MONITOR DESCRIPTION

The throttle position sensor varies its resistance with the angle of the throttle valve. The ECM applies a regu-

lated reference voltage to the throttle position sensor “+” terminal and calculates the angle of the throttle

valve based on the voltage present at the throttle position sensor “signal” terminal.

When the throttle valve is near the fully closed position, the output voltage of the throttle position sensor is

low. When it is near the fully open position, the output voltage is high.

The ECM checks the indicated angle of the throttle valve during “stop and go” conditions. If the indicated

angle (or voltage) in the “closed throttle” position is out of the specified range, the ECM interprets this as a

malfunction in the throttle position sensor and sets a DTC.

MONITOR STRATEGY

Related DTCs

P0121

Throttle position sensor rationality

Main sensors

Throttle position sensor

Required sensors/components

Related sensors

Vehicle speed sensor

Frequency of operation

Continuous

Duration

Within 10 seconds

MIL operation

2 driving cycles

Sequence of operation

None

TYPICAL ENABLING CONDITION

Specification

Item

Minimum

Maximum

The monitor will run whenever the follow-

See ”List of Disable a Monitor” (On page 05-25)

ing DTCs are not present

Throttle valve position

Closed angle position

”Stop and Go”

4 times

-

”Stop and go” is defined as follows:

”Stop” indicates a vehicle speed of 0 mph (0 km/h). ”Go” indicates a vehicle speed of 18.6 mph (30 km/h).

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

26.2_ or more

Throttle valve at closed angle position

Less than 7.4_

COMPONENT OPERATING RANGE

Parameter

Standard Value

Throttle valve at closed angle position

Between 7.5_ and 21_

05-95

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the hand−held tester or the OBD II scan tool. Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio was lean or rich,

etc. at the time of the malfunction.

1

CHECK OTHER DTC OUTPUT(IN ADDITION P0121)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Turn the ignition switch ON and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Select the item ”DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES”.

(d) Read the DTCs.

Result:

Display (DTC output)

Proceed to

”P0121” and other DTCs

A

P0121

B

HINT:

If any other codes besides P0121 is output, perform the troubleshooting for those DTCs first.

B

REPLACE THROTTLE POSITION SENSOR

A

GO TO RELEVANT DTC CHART (See page 05-35)

05-96

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05CTU-02

DTC

P0125

INSUFFICIENT COOLANT TEMPERATURE

FOR CLOSED LOOP FUEL CONTROL

CIRCUIT DESCRIPTION

Refer to DTC P0115 on page 05-80.

DTC No.

DTC Detection Condition

Trouble Area

If the engine coolant temperature (ECT) was less than -6.6°C

(20_F) when starting the engine, and 20 minutes after the en-

gine start, the ECT sensor still indicates below 20°C (68_F)

If the ECT was between -6.6°C (20_F) and 10°C (50_F) when

F Cooling system

P0125

start, 5 minutes after the start, the ECT sensor still indicates

F Engine coolant temperature sensor

below 20°C (68_F)

F Thermostat

If the ECT was greater than 10°C (50_F) when starting the

engine, and 2 minutes after the engine start, ECT sensor still

indicates below 20°C (68_F)

MONITOR DESCRIPTION

The engine coolant temperature (ECT) sensor is used to monitor the temperature of the engine coolant. The

resistance of the sensor varies with the actual coolant temperature. The ECM applies a voltage to the sensor

and the varying resistance of the sensor causes the signal voltage to vary. The ECM monitors the ECT signal

voltage after engine start-up. If, after sufficient time has passed, the sensor still reports that the engine is

not warm enough for closed-loop fuel control, the ECM interprets this as a fault in the sensor or cooling sys-

tem.

Example:

The engine coolant temperature was 0_C (32_F) at engine start. After 5 minutes running time, the coolant

temperature sensor still indicates that the engine is not warm enough to begin air-fuel ratio feedback control.

The ECM interprets this as a fault in the sensor or cooling system and will set a DTC.

MONITOR STRATEGY

Related DTCs

P0125

Insufficient coolant temperature for closed loop fuel control

Main sensors

Engine coolant temperature sensor, cooling system, thermostat

Required sensors/components

Related sensors

Mass air flow sensor

Frequency of operation

Continuous

F 20 minutes

F 5 minutes

Duration

F 2 minutes

(Depending on ECT at engine start)

MIL operation

2 driving cycles

Sequence of operation

None

TYPICAL ENABLING CONDITIONS

Specification

Item

Minimum

Maximum

The monitor will run whenever the follow-

See ”List of Disable a Monitor” table (On page 05-25)

ing DTCs are not present

Intake air amount per second

0.1 g/sec

-

Fuel cut

OFF

05-97

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

Time until detected engine coolant temperature (ECT)

(a), (b) or (c)

reaches the closed-loop enabling temperature

(a) ECT at engine start is 10_C (50_F) or more

2 minutes or more

(b) ECT at engine start is between -6.7_C (20_F) and 10_C

5 minutes or more

(50_F)

(c) ETC at engine start is -6.7_C (20_F) or less

20 minutes or more

WIRING DIAGRAM

Refer to DTC P0115 on page 05-80.

INSPECTION PROCEDURE

HINT:

F

If DTCs P0115, P0116, P0117, P0118 and P0125 are output simultaneously, the engine coolant tem-

perature sensor circuit may be open or short. Perform the troubleshooting of DTC P0115, P0117 or

P0118 first.

F

Read freeze frame data using the hand−held tester or the OBD II scan tool. Freeze frame data records

the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determin-

ing whether the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio

was lean or rich, etc. at the time of the malfunction.

1

CHECK OTHER DTC OUTPUT(IN ADDITION TO DTC P0125)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Turn the ignition switch ON and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Select the item ”DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES”.

(d) Read the DTCs.

Result:

Display (DTC output)

Proceed to

P0125

A

P0125 and other DTCs

B

HINT:

If any other codes besides P0125 are output, perform the troubleshooting for those DTCs first.

B

GO TO RELEVANT DTC CHART

(See page 05-35)

A

2

INSPECT THERMOSTAT (See page 16-3)

NG REPLACE THERMOSTAT

(See page 16-11)

OK

REPLACE ENGINE COOLANT TEMPERATURE SENSOR

05-98

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

052NG-09

DTC

P0128

COOLANT THERMOSTAT (COOLANT

TEMPERATURE BELOW THERMOSTAT

REGULATING TEMPERATURE)

HINT:

This is the purpose of the ”thermostat” malfunction detection.

CIRCUIT DESCRIPTION

If the engine coolant temperature (ECT) does not reach 75°C (167°F) despite sufficient warm - up time has

elapsed.

DTC No.

DTC Detection Condition

Trouble Area

Condition (a), (b) and (c):

F Thermostat

(a) Cold start

F Cooling system

P0128

(b) After engine is warmed up

F Engine coolant temperature sensor

(c) Engine coolant temperature is less than 75°C (167°F)

F ECM

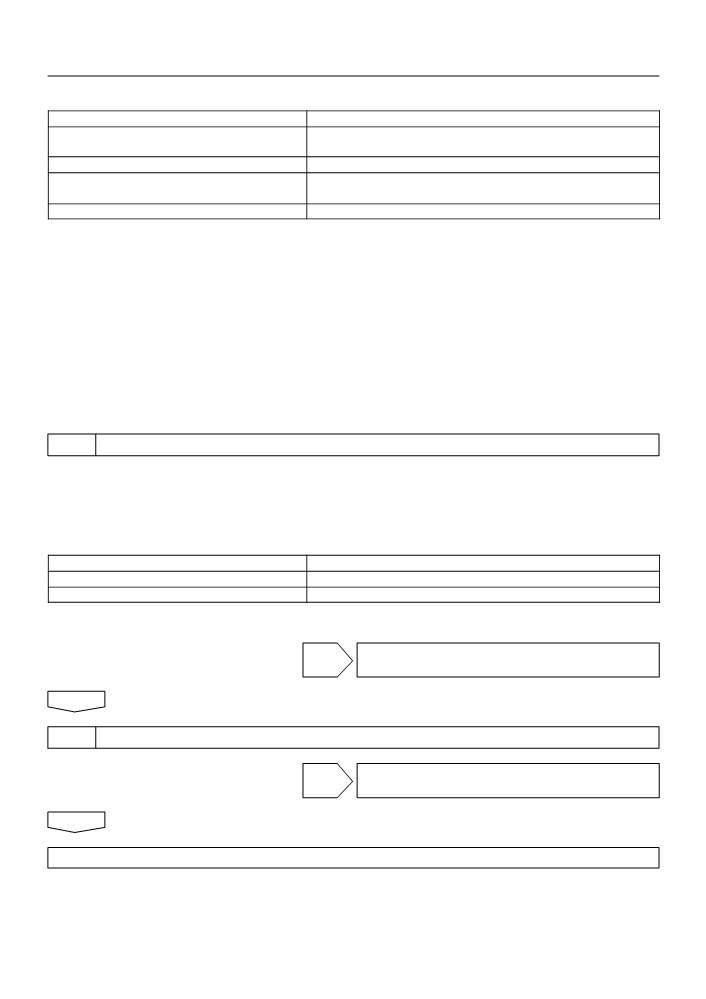

MONITOR DESCRIPTION

5 sec

Estimated ECT

Threshold

(75_C (167_F))

Indicated coolant temp. reading

ECT

Time

DTC set (after 2 driving cycle)

A82385

The ECM estimates the engine coolant temperature (ECT) based on starting temperature, engine loads, and

engine speeds. The ECM then compares the estimated ECT with the actual ECT. When the estimated ECT

reaches 75_C (167_F) the ECM checks the actual ECT. If the actual ECT is less than 75_C (167_F), the ECM

will interpret this as a fault in the thermostat or engine cooling system or thermostat and set a DTC.

05-99

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

MONITOR STRATEGY

Related DTCs

P0128

Thermostat

Main sensors

Engine coolant temperature sensor, engine cooling system, thermostat

Required sensors/components

Related sensors

Intake air temperature sensor, vehicle speed sensor

Frequency of operation

Once per drive cycle

Duration

15 minutes

MIL operation

2 driving cycles

Sequence of operation

None

TYPICAL ENABLING CONDITIONS

Specification

Item

Minimum

Maximum

The monitor will run whenever the follow-

See ”List of Disable a Monitor” (On page 05-25)

ing DTCs are not present

Battery voltage

11.0 V

-

Intake air temperature (at engine start)

-10_C (14_F)

35_C (95_F)

Engine coolant temperature

-10_C (14_F)

35_C (95_F)

(at engine start)

Engine coolant temperature - Intake air

-15_C (-27_F)

7_C (12.6_F)

temperature (at engine start)

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

(1) Estimated engine coolant temperature

75_C (167_F) or more

(2) Engine coolant temperature sensor output value

Less than 75_C (167_F)

Duration period of both (1) and (2)

5 seconds or more

COMPONENT OPERATING RANGE

Parameter

Standard Value

Engine coolant temperature sensor output value after

75_C (167_F) or more

warm-up

MONITOR RESULT (MODE 06 DATA)

Conversion

Test ID

Comp ID

Description of Test Data

Description of Test Limit

Unit

Factor

Difference between estimated and

actual engine coolant tempera-

Multiply

tures is calculated by ECM.

$08

$81

Malfunction criteria for thermostat

Degree C

by 0.625 and

The value stored when estimated

minus 40

coolant temperature

=75_C (167_F)

Refer to page 05-27 for the detailed information on Checking Monitor Status.

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the hand−held tester or the OBD II scan tool. Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio was lean or rich,

etc. at the time of the malfunction.

05-100

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

1

CHECK COOLING SYSTEM

(a) Check that there is a defect in the cooling system which causes overcool, such as abnormal radiator

fan operation, modified cooling system and so on.

NG REPAIR OR REPLACE COOLING SYSTEM

OK

2

INSPECT THERMOSTAT (See page 16-3)

NG REPLACE THERMOSTAT

(See page 16-11)

OK

3

CHECK OTHER DTC OUTPUT(IN ADDITION TO DTC P0128)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Turn the ignition switch ON and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Select the item ”DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES”.

(d) Read the DTCs.

Result:

Display (DTC output)

Proceed to

P0128

A

P0128 and other DTCs

B

HINT:

If any other codes besides P0128 is output, perform the troubleshooting for those DTCs first.

B

GO TO RELEVANT DTC CHART

(See page 05-35)

A

REPLACE ECM (See page 10-11)

05-101

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05DIJ-01

DTC

P0130

OXYGEN SENSOR CIRCUIT MALFUNCTION

(BANK 1 SENSOR 1)

DTC

P2195

OXYGEN SENSOR SIGNAL STUCK LEAN

(BANK 1 SENSOR 1)

DTC

P2196

OXYGEN SENSOR SIGNAL STUCK RICH

(BANK 1 SENSOR 1)

CIRCUIT DESCRIPTION

The rear heated oxygen sensor is used to monitor oxygen concentration in the exhaust gas. For optimum

catalytic converter operation, the air fuel mixture must be maintained near the ideal ”stoichiometric” ratio.

The heated oxygen sensor output voltage changes suddenly in the vicinity of the stoichiometric ratio. The

ECM adjusts the fuel injection time so that the air-fuel ratio is nearly stoichiometric.

When the air-fuel ratio becomes LEAN, the oxygen concentration in the exhaust gas increases. And the

heated oxygen sensor informs the ECM of the LEAN condition (low voltage, i.e. less than 0.45 V).

When the air-fuel ratio is RICHER than the stoichiometric air-fuel ratio, the oxygen will be vanished from

the exhaust gas. And the heated oxygen sensor informs the ECM of the RICH condition (high voltage, i.e.

more than 0.45 V).

Ideal Air-Fuel Mixture

Heater

Solid Electrolyte

(Zirconia Element)

Platinum Electrode

Element

Cover

Richer - Air Fuel Ratio - Leaner

Air

Exhaust Gas

A

A

A-A Section

A66651

DTC No.

DTC Detection Condition

Trouble Area

Output voltage of heated oxygen sensor remains at 0.4 V or

F Open or short in heated oxygen sensor (bank 1 sensor 1)

P0130

more, or 0.5 V or less, during idling after engine is warmed up

circuit

(2 trip detection logic)

F Heated oxygen sensor (bank 1 sensor 1)

Output voltage of heated oxygen sensor remains at 0.5 V or

F Heated oxygen sensor heater (bank 1 sensor 1)

P2195

less, during idling after engine is warmed up (2 trip detection

F EFI relay

logic)

F Air induction system

Output voltage of heated oxygen sensor remains at 0.4 V or

F Fuel pressure

F Injector

P2196

more, during idling after engine is warmed up (2 trip detection

logic)

F ECM

HINT:

F

Sensor 1 refers to the sensor closest to the engine assembly.

F

The output voltage of the heated oxygen sensor and the short-term fuel trim value can be read using

the hand-held tester or the OBD ll scan tool.

05-102

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

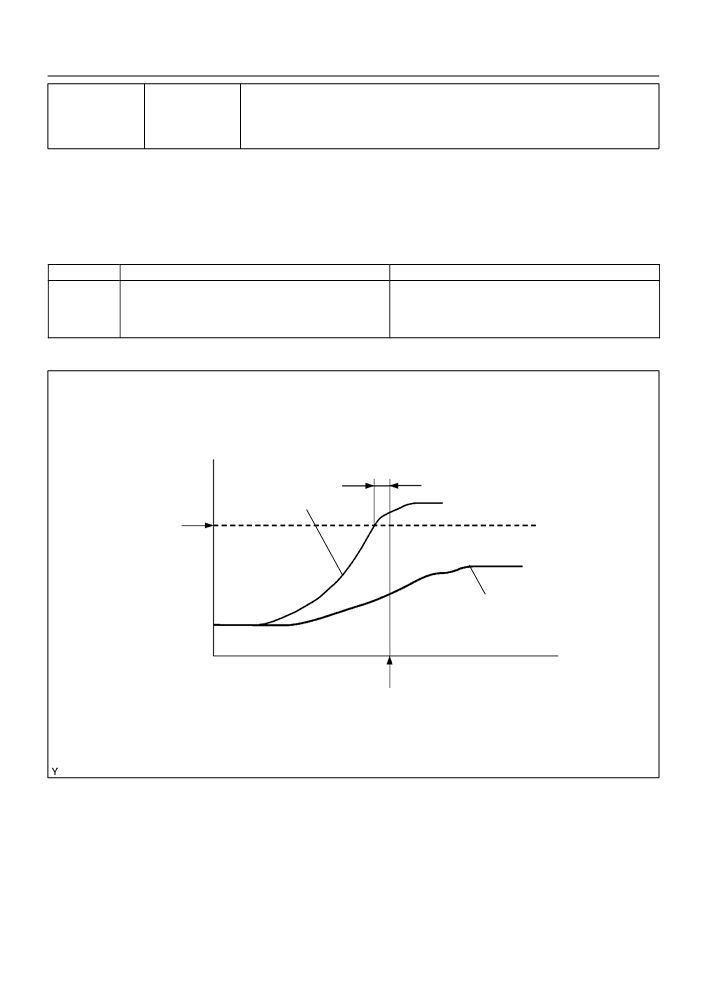

MONITOR DESCRIPTION

Rich

FAIL

0.5

PASS

FAIL

0.4

FAIL

Lean

Pass / Fail definition of voltage malfunction

Time

A85193

The engine control module (ECM) uses the heated oxygen sensor information to regulate the air-fuel ratio

near to the stoichiometric air-fuel ratio. The sensor detects oxygen levels in the exhaust gases and sends

this signal to the ECM. This maximizes the catalytic converter’s ability to purify the exhaust gases.

The heated oxygen sensor element consists of the platinum coated zirconia and heating element. The inner

surface of sensor element is exposed to the outside air, and the outer surface of sensor element is exposed

to the exhaust gases. The sensor generates between 0 V and 1 V of the voltage output in response to the

oxygen concentration in the exhaust gases. The sensor’s output voltage varies suddenly in the vicinity of

the stoichiometric air-fuel ratio.

Under normal condition, the output voltage from the heated oxygen sensor alternates between RICH and

LEAN sides periodically. When it is 0.4 V or less, the air-fuel ratio is judged as LEAN.

If the heated oxygen sensor outputs RICH signal (or LEAN signal) constantly, or if the heated oxygen sensor

cannot output enough voltage to reach the minimum specification, the ECM interprets this as a malfunction

in the heated oxygen sensor and sets a DTC.

MONITOR STRATEGY

P0130

Front heated oxygen sensor voltage is constant

Related DTCs

P2195

Front heated oxygen sensor voltage is constant at lean side

P2196

Front heated oxygen sensor voltage is constant at rich side

Main sensors

Front heated oxygen senor

Required sensors/components

Related sensors

Crank shaft position sensor, vehicle speed sensor

Frequency of operation

Once per drive cycles

Duration

18 to 36 seconds x 3

MIL operation

2 driving cycles

Sequence of operation

None

05-103

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

TYPICAL ENABLING CONDITION

Specification

Item

Minimum

Maximum

The monitor will run whenever the follow-

See ”List of Disable a Monitor” (On page 05-25)

ing DTCs are not present

There is history of following condition (a)

20 seconds (Continuously)

-

and (b) a met:

(a) Vehicle speed

25 mph (40 km/h)

-

(b) Engine speed

900 rpm

-

Time after engine start

120 seconds

-

Idle

ON

Fuel system status

Closed loop

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

P0130:

Sensor voltage is 0.5 V or less for 18 seconds or more

3 times or more

Sensor voltage is 0.4 V or more for 18 seconds or more

P2195:

Front heated oxygen sensor voltage is 0.5 V or less for 18

3 times or more

seconds or more

P2196:

Front heated oxygen sensor voltage is 0.4 V or more for 18

3 times or more

seconds or more

COMPONENT OPERATING RANGE

Parameter

Standard Value

In the normal condition, the heated oxygen sensor voltage

0 to 1 V

MONITOR RESULT (MODE 06 DATA)

Conversion fac-

Test ID

Comp ID

Description of test data

Description of test limit

Unit

tor

Not supported by mode $06, but

$03

-

-

-

-

by mode $05

Refer to page 05-27 for detailed information on Checking Monitor Status.

05-104

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

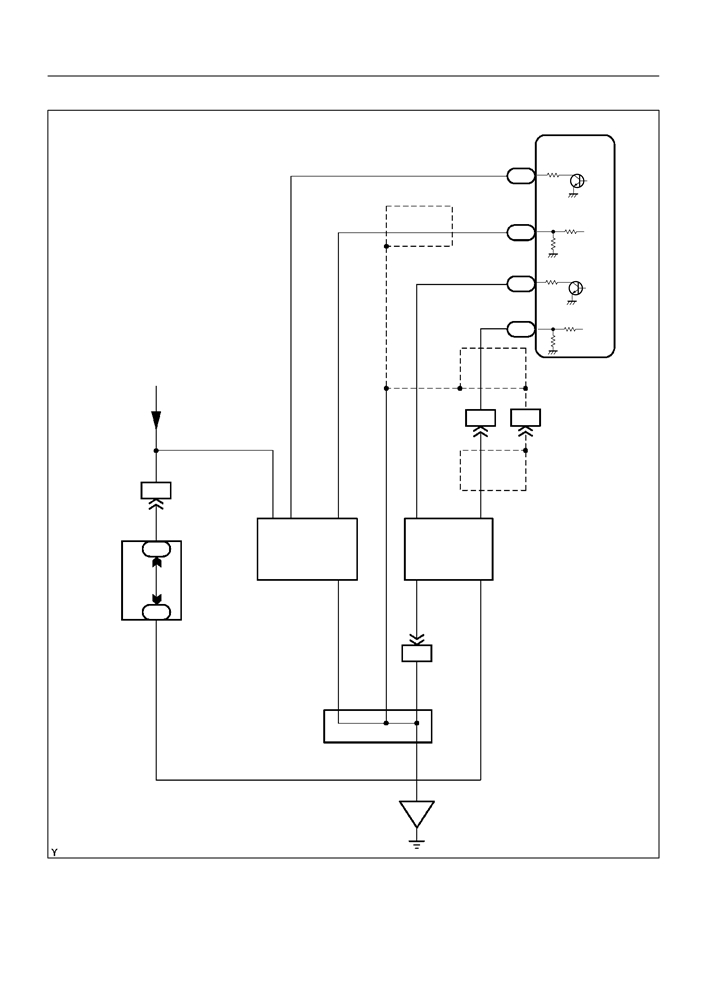

WIRING DIAGRAM

ECM

4

HT1A

P

E4

(*1)

23

OX1A

B

E4

4

HT1B

P-B

E5

P

(*1)

21

OX1B

E4

From Terminal

3 of EFI Relay

W

B

(*1)

II2

18

II2

9

BR P-B

B

W

(*1)

B

II1

6

2

1

3

2

4

B

H8

+B HT OX

HT

OX

Heated

1

4B

Oxygen

Sensor

Center

E1

E1

+B

J/B

H5

4

3

1

(Bank 1

Sensor 2)

Heated

4

4B

Oxygen

BR

Sensor

BR

(Bank 1

II2

8

Sensor 1)

B

BR

B

A

A

A

J4

A

Junction Connector

BR

*1: Shielded

EB

A84873

05-105

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

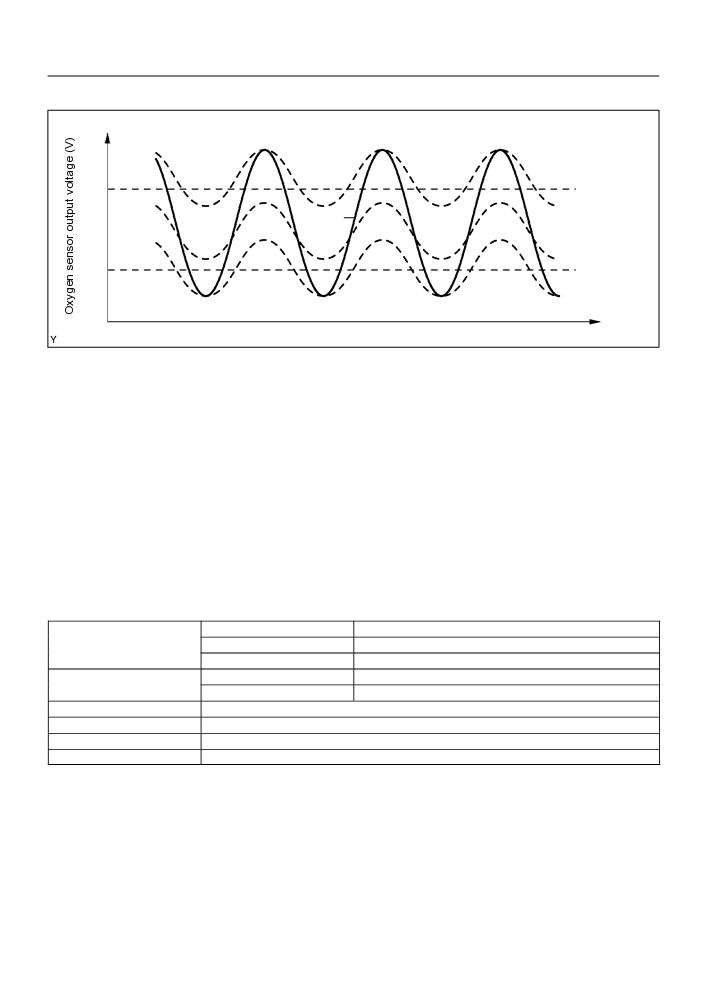

CONFIRMATION DRIVING PATTERN

40 seconds

40 seconds

40 seconds

Vehicle speed

or more

or more

or more

25 mph

(40 km/h)

(d)

(d)

(d)

Idling(c)

(e)

(e)

(f)

IgnitionOFF

120 seconds

20 seconds

20 secconds

(a)(b)

30 seconds

or more

or more

or more

A85081

(a) Connect the hand-held tester to the DLC3.

(b) Switch the hand-held tester from the ”normal mode” to the ”check mode” (See page 05-11).

(c)

Start the engine and let the engine idle for 120 seconds or more.

(d) Drive the vehicle at 25 mph (40 km/h) or more for 40 seconds or more.

(e) Let the engine idle for 20 seconds or more. Perform steps (d) and (e) at least 3 times.

(f)

Let the engine idle for 30 seconds.

HINT:

If a malfunction exists, the MIL will be illuminated on the multi information display during step (f).

NOTICE:

If the conditions in this test are not strictly followed, detection of a malfunction will not occur.

If you do not have the hand-held tester, turn the ignition switch OFF after performing steps from (c)

to (f), then perform steps from (c) to (f) again.

INSPECTION PROCEDURE

HINT:

Hand-held tester only:

Narrowing down the trouble area is possible by performing ”A/F CONTROL” ACTIVE TEST (heated oxygen

sensor or other trouble areas can be distinguished).

(a) Perform ACTIVE TEST using hand-held tester (A/F CONTROL).

HINT:

”A/F CONTROL” is the ACTIVE TEST which changes the injection volume to -12.5 % or +25 %.

(1)

Connect the hand-held tester to the DLC3 on the vehicle.

(2)

Turn the ignition switch ON.

(3)

Warm up the engine by running the engine speed at 2,500 rpm for approximately 90 seconds.

(4)

Select the item ”DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / A/F CONTROL”.

(5)

Perform ”A/F CONTROL” with the engine in an idle condition (press the right or left button).

Result:

Heated oxygen sensor reacts in accordance with increase and decrease of injection volume

+25 % rich output: More than 0.5 V,

-12.5 % lean output: Less than 0.4 V