Toyota Corolla (2004+). Manual - part 56

05-64

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

4

CHECK HARNESS AND CONNECTOR(HEATED OXYGEN SENSOR - ECM,

HEATED OXYGEN SENSOR - EFI RELAY)

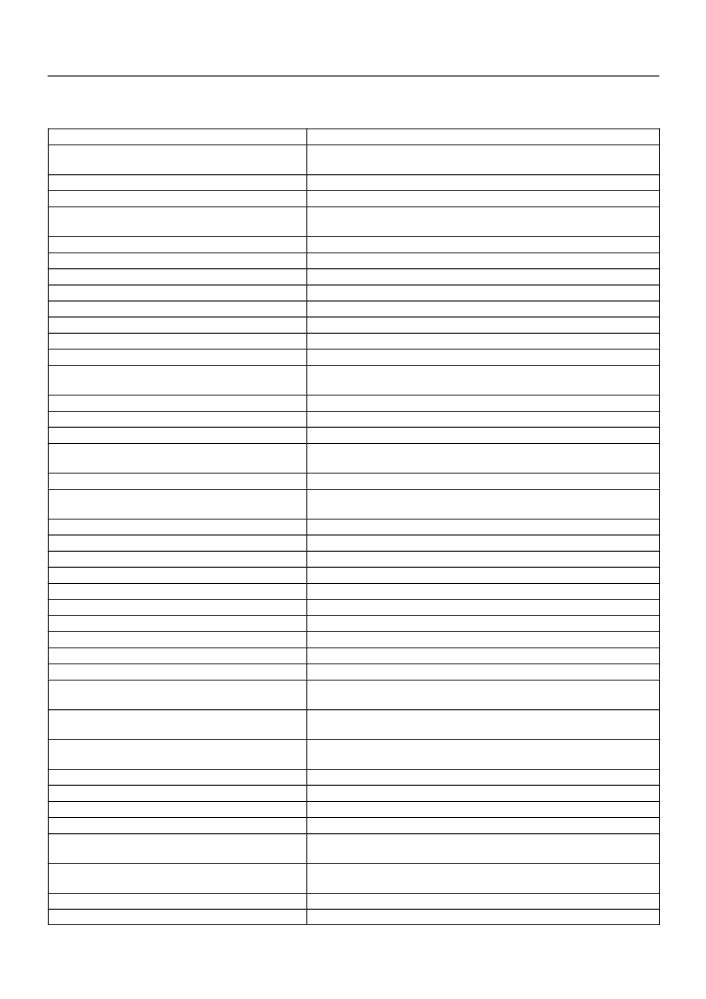

Wire Harness Side:

(a)

Check the harness and connector between the ECM and

Heated Oxygen Sensor Connector

heated oxygen sensor connectors.

(1)

Disconnect the H5 or H8 heated oxygen sensor

H5 Sensor 1

H8

Sensor 2

connector.

+B

HT

+B

(2)

Disconnect the E4 or E5 ECM connector.

HT

(3)

Check the resistance between the wire harness

side connectors.

Standard (Check for open):

Front View

A84757

Tester Connection

Specified Condition

HT (H5-1) - HT1A (E4-4)

Below 1 W

HT (H8-2) - HT1B (E5-4)

Below 1 W

Standard (Check for short):

E4

E5

Tester Connection

Specified Condition

HT (H5-1) or HT1A (E4-4) - Body ground

10 kW or higher

HT (H8-2) or HT1B (E5-4) - Body ground

10 kW or higher

(4)

Reconnect the heated oxygen sensor connector.

(5)

Reconnect the ECM connector.

HT1A

HT1B

(b)

Check the harness and connector between the heated

ECM connector

A65747

oxygen sensor connector and EFI relay.

(1)

Disconnect the H5 or H8 heated oxygen sensor

connector.

Engine Room R/B:

(2)

Remove the EFI relay from the engine room R/B.

(3)

Check the resistance between the wire harness

side connectors.

Standard (Check for open):

Tester Connection

Specified Condition

EFI Relay

+B (H5-2) - EFI relay (3)

Below 1 W

+B (H8-1) - EFI relay (3)

Below 1 W

A65750

Standard (Check for short):

Tester Connection

Specified Condition

+B (H5-2) or EFI relay (3) - Body ground

10 kW or higher

+B (H8-1) or EFI relay (3) - Body ground

10 kW or higher

(4)

Reconnect the heated oxygen sensor connector.

(5)

Reinstall the EFI relay.

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

REPLACE ECM (See page

10-11)

05-65

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

059VF-08

DTC

P0100

MASS OR VOLUME AIR FLOW CIRCUIT

DTC

P0102

MASS OR VOLUME AIR FLOW CIRCUIT

LOW INPUT

DTC

P0103

MASS OR VOLUME AIR FLOW CIRCUIT

HIGH INPUT

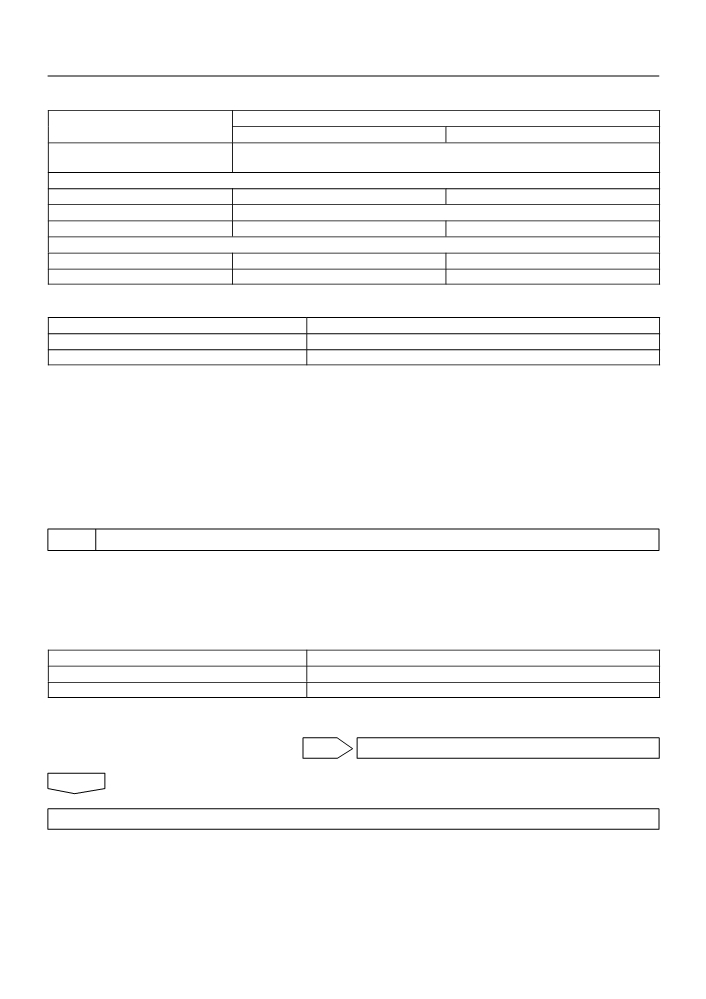

CIRCUIT DESCRIPTION

The MAF (Mass Air Flow) sensor measures the amount of air flowing through the throttle valve. The ECM

uses this information to determine the fuel injection time and provide a proper air-fuel ratio. Inside the MAF

sensor, there is a heated platinum wire exposed to the flow of intake air.

By applying a specific current to the wire, the ECM heats this wire to a given temperature. The flow of incom-

ing air cools the wire and an internal thermister, changing their resistance. To maintain a constant current

value, the ECM varies the voltage applied to these components in the MAF sensor. The voltage level is pro-

portional to the airflow through the sensor and the ECM interprets this voltage as the intake air amount.

The circuit is constructed so that the platinum hot wire and the temperature sensor provides a bridge circuit,

with the power transistor controlled so that the potential of A and B remains equal to maintain the set temper-

ature.

B+

Temperature sensor

Power Transistor

Platinum Hot Wire

(Heater)

A

B

Output

Voltage

Temperature

sensor

Platinum Hot Wire (Heater)

A80089

DTC No.

DTC Detection Condition

Trouble Area

When the mass air flow sensor circuit has an open or short for

P0100

more than 3 seconds.

F Open or short in mass air flow sensor circuit

When the mass air flow sensor circuit has an open for more

P0102

F Mass air flow sensor

than 3 seconds.

F ECM

When the mass air flow sensor circuit has a short for more

P0103

than 3 seconds.

HINT:

After confirming DTC P0100, P0102 or P0103, confirm the mass air flow ratio in the ”DIAGNOSIS / EN-

HANCED OBD II / DATA LIST / ALL” using the hand-held tester or the OBD II scan tool.

05-66

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

Air Flow Value (gm/s)

Malfunction

F Mass air flow sensor power source circuit open

Approx. 0.0

F VG circuit open or short

271.0 or more

F EVG circuit open

MONITOR DESCRIPTION

If there is a defect in the sensor or an open or short circuit, the voltage level will deviate outside the normal

operating range. The ECM interprets this deviation as a defect in the MAF sensor and sets a DTC.

Example:

When the sensor voltage output is less than 0.2 V or more than 4.9 V and if either the condition continues

for more than 3 seconds.

MONITOR STRATEGY

P0100

Mass air flow sensor circuit range check (fluttering)

Related DTCs

P0102

Mass air flow sensor circuit range check (low voltage)

P0103

Mass air flow sensor circuit range check (high voltage)

Required sensors/components

Mass air flow sensor

Frequency of operation

Continuous

Duration

3 seconds

Immediately (when engine speed at 4,000rpm or less)

MIL operation

2 driving cycles (when engine speed at 4,000 rpm or more)

Sequence of operation

None

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the follow-

See ”List of Disable a Monitor” (On page 05-25)

ing DTCs are not present

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

P0100:

Mass air flow sensor voltage

Less than 0.2 V or more than 4.9 V

P0102:

Mass air flow sensor voltage

Less than 0.2 V

P0103:

Mass air flow sensor voltage

More than 4.9 V

COMPONENT OPERATING RANGE

Parameter

Standard Value

Mass air flow sensor voltage

0.4 to 2.2 V

05-67

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

WIRING DIAGRAM

M1

Mass Air Flow Sensor

ECM

G

24

3

VG

VG

E4

+B

B

1

32

From

E2G

2

L-W

EVG

E4

Terminal 3 of

EFI Relay

(See page 05-273)

A76970

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the hand−held tester or the OBD II scan tool. Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio was lean or rich,

etc. at the time of the malfunction.

1

READ VALUE OF HAND-HELD TESTER OR OBD II SCAN TOOL(MASS AIR FLOW

RATE)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Start the engine.

(c)

Push the hand-held tester or the OBD II scan tool main switch ON.

(d) Select the item ”DIAGNOSIS / ENHANCED OBD II / DATA LIST / ALL / MAF” and read its value dis-

played on the hand-held tester or the OBD II scan tool.

Result:

Air Flow Rate (gm/s)

Proceed to

0.0

A

271.0 or more

B

Between 1.0 and 270.0 (*1)

C

*1: The value must be changed when the throttle valve is opened or closed.

B

Go to step 6

C CHECK FOR INTERMITTENT PROBLEMS

(See page 05-41)

A

05-68

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

2

INSPECT MASS AIR FLOW SENSOR(POWER SOURCE)

(a) Turn the ignition switch ON.

Wire Harness Side:

(b) Disconnect the M1 mass air flow sensor connector.

M1

Mass Air Flow Sensor Connector

(c)

Measure the voltage between the terminal of the wire har-

+B (+)

ness side connector and body ground.

Standard:

Tester Connection

Specified Condition

+B (M1-1) - Body ground

9 to 14 V

Front View

(d) Reconnect the mass air flow sensor connector.

A54396

NG Go to step 5

OK

3

INSPECT ECM(VG VOLTAGE)

(a) Start the engine.

E4

(b) Measure the voltage between the terminals of the E4

ECM connector.

HINT:

The shift position should be P or N and the A/C switch should

be turned OFF.

Standard:

VG (+)

EVG (-)

Tester Connection

Condition

Specified Condition

ECM Connector

A18294

VG (E4-24) -

Engine is idling

1.1 to 1.5 V

EVG (E4-32)

NG REPLACE ECM (See page 10-11)

OK

05-69

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

4

CHECK HARNESS AND CONNECTOR(MASS AIR FLOW SENSOR - ECM)

(a) Disconnect the M1 mass air flow sensor connector.

Wire Harness Side:

(b) Disconnect the E4 ECM connector.

M1

Mass Air Flow Sensor Connector

(c)

Check the resistance between the wire harness side con-

nectors.

Standard (Check for open):

Tester Connection

Specified Condition

VG (M1-3) - VG (E4-24)

E2G

VG

Below 1 W

E2G (M1-2) - EVG (E4-32)

Front View

A54396

Standard (Check for short):

Tester Connection

Specified Condition

VG (M1-3) or VG (E4-24) - Body ground

10 kW or higher

(d) Reconnect the mass air flow sensor connector.

E4

(e) Reconnect the ECM connector.

NG REPAIR OR REPLACE HARNESS OR

VG

EVG

CONNECTOR

ECM Connector

A65745

OK

REPLACE MASS AIR FLOW SENSOR

05-70

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

5

CHECK HARNESS AND CONNECTOR(MASS AIR FLOW SENSOR - EFI RELAY)

Engine Room R/B:

(a) Remove the EFI relay from the engine room R/B.

(b) Disconnect the M1 mass air flow sensor connector.

(c)

Check the resistance between the wire harness side con-

nectors.

Standard (Check for open):

Tester Connection

Specified Condition

EFI Relay

+B (M1-1) - EFI relay (3)

Below 1 W

Standard (Check for short):

A65750

Tester Connection

Specified Condition

+B (M1-1) or EFI relay (3) - Body ground

10 kW or higher

Wire Harness Side:

(d) Reconnect the mass air flow sensor connector.

(e) Reinstall the EFI relay.

M1

+B

NG REPAIR OR REPLACE HARNESS OR

Mass Air Flow Sensor Connector

A54396

CONNECTOR

OK

CHECK FOR ECM POWER SOURCE CIRCUIT (See page 05-273)

6

INSPECT ECM(SENSOR GROUND)

(a) Check the resistance between the terminals of the E4

ECM connector.

E4

Standard:

Tester Connection

Specified Condition

EVG (E4-32) - Body ground

Below 1 W

EVG

ECM Connector

A18294

NG REPLACE ECM (See page 10-11)

OK

05-71

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

7

CHECK HARNESS AND CONNECTOR(MASS AIR FLOW SENSOR - ECM)

(a) Disconnect the M1 mass air flow sensor connector.

Wire Harness Side:

(b) Disconnect the E4 ECM connector.

M1

Mass Air Flow Sensor Connector

(c)

Check the resistance between the wire harness side con-

nectors.

Standard (Check for open):

Tester Connection

Specified Condition

VG (M1-3) - VG (E4-24)

E2G

VG

Below 1 W

E2G (M1-2) - EVG (E4-32)

Front View

A54396

Standard (Check for short):

Tester Connection

Specified Condition

VG (M1-3) or VG (E4-24) - Body ground

10 kW or higher

(d) Reconnect the ECM connector.

E4

(e) Reconnect the mass air flow sensor connector.

VG

EVG

ECM Connector

A65745

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

REPLACE MASS AIR FLOW SENSOR

05-5

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

05285-11

LOCATION

Power Steering OIl Pressure Switch

ECM

Ignition Coil Assy

Heated Oxygen Sensor

Fuel Injector Assy

(Bank 1 Sensor 1)

Camshaft Timing OIl

Mass Air Flow Sensor

Control Valve Assy

Heated Oxygen Sensor

(Bank 1 Sensor 2)

Crankshaft

Instrument Panel J/B:

Position Sensor

F

IGN Fuse

F

Circuit Opening Relay

F

ST Relay

DLC3

Vacuum Switching Valve

(for EVAP)

Engine Room R/B and

Fusible Link block:

F

EFI Relay

Knock Sensor

F

EFI Fuse

Idle Speed Control

Engine Coolant Temperature Sensor

Valve Assy

Throttle Position Sensor

Park/Neutral Position Switch *1

Camshaft Position Sensor

Vacuum Switching Valve

(for Charcoal Canister)

Vapor Pressure Sensor

Charcoal Canister Assy

*1: Only for A/T

A84398

05-23

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05DIE-01

TOYOTA/LEXUS PART AND SYSTEM NAME LIST

This reference list indicates the part names used in this manual along with their definitions.

TOYOTA/LEXUS name

Definition

Toyota HCAC system, Hydro-carbon Adsorptive Catalyst

HC adsorptive three-way catalytic converter

(HCAC) system, HC adsorptive three-way catalyst

Variable Valve Timing sensor, VVT sensor

Camshaft position sensor

Variable valve timing system, VVT system

Camshaft timing control system

Camshaft timing oil control valve, Oil control valve, OCV,

Camshaft timing oil control valve

VVT, VSV

Variable timing and lift

Camshaft timing and lift control

Crankshaft position sensor ”A”

Crankshaft position sensor

Engine speed sensor

Crankshaft position sensor

THA

Intake air temperature

Knock control module

Engine knock control module

Knock sensor

Engine knock sensor

Mass or volume air flow circuit

Mass air flow sensor circuit

Vacuum sensor

Manifold air pressure sensor

Internal control module, Control module, Engine control

Power train control module

ECM, PCM

FC idle

Deceleration fuel cut

Idle air control valve

Idle speed control

VSV for CCV, Canister close valve, VSV for canister control

Evaporative emissions canister vent valve

VSV for EVAP, Vacuum switching valve assembly No. 1,

Evaporative emissions canister purge valve

EVAP VSV, Purge VSV

VSV for pressure switching valve, Bypass VSV

Evaporative emission pressure switching valve

Vapor pressure sensor, EVAP pressure sensor, Evaporative

Fuel tank pressure sensor

emission control system pressure sensor

Charcoal canister

Evaporative emissions canister

ORVR system

On-boad refueling vapor recovery system

Intake manifold runner control

Intake manifold tuning system

Intake manifold runner valve, IMRV, IACV (runner valve)

Intake manifold tuning valve

Intake control VSV

Intake manifold tuning solenoid valve

AFS

Air fuel ratio sensor

O2 sensor

Heated oxygen sensor

Oxygen sensor pumping current circuit

Oxygen sensor output signal

Oxygen sensor reference ground circuit

Oxygen sensor signal ground

Accel position sensor

Accelerator pedal position sensor

Throttle actuator control motor, Actuator control motor, Elec-

Electronic throttle actuator

tronic throttle motor, Throttle control motor

Electronic throttle control system, Throttle actuator control

Electronic throttle control system

system

Throttle/pedal position sensor, Throttle/pedal position switch,

Throttle position sensor

Throttle position sensor/switch

Turbo press sensor

Turbocharger pressure sensor

Turbo VSV

Turbocharger pressure control solenoid valve

P/S pressure switch

Power-steering pressure switch

VSV for ACM

Active control engine mount

Speed sensor, Vehicle speed sensor ”A”, Speed sensor for

Vehicle speed sensor

skid control ECU

ATF temperature sensor, Trans. fluid temp. sensor, ATF

Transmission fluid temperature sensor

temperature sensor ”A”

Electronic controlled automatic transmission, ECT

Electronically controlled automatic

Intermediate shaft speed sensor ”A”

Counter gear speed sensor

05-24

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

TOYOTA/LEXUS name

Definition

Output speed sensor

Output shaft speed sensor

Input speed sensor, Input turbine speed sensor ”A”, Speed

Input turbine speed sensor

sensor (NT), Turbine speed sensor

PNP switch, NSW

Park/neutral position switch

Pressure control solenoid

Transmission pressure control solenoid

Shift solenoid

Transmission shift solenoid valve

Transmission control switch, Shift lock control unit

Shift lock control module

Engine immobiliser system, Immobiliser system

Vehicle anti-theft system

05-72

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

052N9-11

DTC

P0101

MASS OR VOLUME AIR FLOW CIRCUIT

RANGE/PERFORMANCE PROBLEM

CIRCUIT DESCRIPTION

Refer to DTCs P0100 on page 05-65.

DTC No.

DTC Detection Condition

Trouble Area

After engine is warmed up, conditions (a) to (d) continue for

more than 10 seconds (2 trip detection logic):

(a) Engine speed less than 900 rpm

(b) Throttle valve fully closed

(c) Mass air flow sensor output greater than 2.2 V

P0101

F Mass air flow sensor

(d) Engine coolant temperature higher than 70_C (158_F)

Conditions (a) and (b) continue for more than 6 seconds: (2 trip

detection logic)

(a) VTA greater than 0.1 V

(b) Mass air flow sensor output less than 0.4 V

MONITOR DESCRIPTION

The MAF (Mass Air Flow) sensor helps the ECM calculates the amount of air flowing through the throttle

valve. The ECM uses this information to determine the fuel injection time and provides a proper air-fuel ratio.

Inside the MAF sensor, there is a heated platinum wire exposed to the flow of intake air. By applying a specific

current to the wire, the ECM heats this wire to a given temperature. The flow of incoming air cools the wire

and an internal thermister, changing their resistance. To maintain a constant current value, the ECM varies

the voltage applied to these components in the MAF sensor. The voltage level is proportional to the air flow

through the sensor and the ECM interprets this voltage as the intake air amount. If there is a defect in the

sensor or an open or short circuit, the voltage level will deviate outside the normal operating range. The ECM

interprets this deviation as a defect in the MAF sensor and sets a DTC.

Example: If the voltage is more than 2.2 V at idle, or less than 0.4 V at idle off, the ECM interprets this as

a defect in the MAF sensor and sets a DTC.

MONITOR STRATEGY

Related DTCs

P0101

Mass air flow sensor rationality

Main sensors

Mass air flow sensor

Required sensors/components

Engine speed sensor, engine coolant tempera-

Related sensors

ture sensor, throttle position sensor

Frequency of operation

Continuous

10 seconds (high voltage)

Duration

6 seconds (Low voltage)

MIL operation

2 driving cycles

Sequence of operation

None

05-73

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

TYPICAL ENABLING CONDITIONS

Specification

Item

Minimum

Maximum

The monitor will run whenever the follow-

See ”List of Disable a Monitor” (On page 05-25)

ing DTCs are not present

High voltage:

Engine speed

-

900 rpm

Idle

ON

Engine coolant temperature

70_C (158_F)

-

Low voltage:

Engine speed

0 rpm

-

Throttle position

0.1 V

-

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

Mass air flow sensor voltage (high voltage)

More than 2.2 V

Mass air flow sensor voltage (low voltage)

Less than 0.4 V

WIRING DIAGRAM

Refer to DTC P0100 on page 05-65.

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the hand−held tester or the OBD II scan tool. Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio was lean or rich,

etc. at the time of the malfunction.

1

CHECK OTHER DTC OUTPUT(IN ADDITION TO DTC P0101)

(a) Connect the hand-held tester or the OBD II scan tool to the DLC3.

(b) Turn the ignition switch ON and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Select the item ”DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES”.

(d) Read the DTCs.

Result:

Display (DTC output)

Proceed to

P0101 and other DTCs

A

P0101

B

HINT:

If any other codes besides P0101 are output, perform the troubleshooting for those DTCs first.

B

REPLACE MASS AIR FLOW SENSOR

A

GO TO RELEVANT DTC CHART (See page 05-35)

05-74

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

059VE-07

DTC

P0110

INTAKE AIR TEMPERATURE CIRCUIT

DTC

P0112

INTAKE AIR TEMPERATURE CIRCUIT LOW

INPUT

DTC

P0113

INTAKE AIR TEMPERATURE CIRCUIT HIGH

INPUT

CIRCUIT DESCRIPTION

The intake air temperature (IAT) sensor, mounted on the mass

(Fig.1)

air flow (MAF) sensor, monitors the intake air temperature. The

IAT sensor has a thermistor that varies its resistance depending

30

on the temperature of the intake air. When the air temperature

20

is low, the resistance in the thermistor increases. When the tem-

10

perature is high, the resistance drops. The variations in resis-

Acceptable

tance are reflected as voltage changes to the ECM terminal.

5

(See Fig. 1).

3

2

The intake air temperature sensor is connected to the ECM.

The 5 V power source voltage in the ECM is applied to the in-

1

take air temperature sensor from terminal THA (THAR) via re-

0.5

sistor R.

0.3

That is, the resistor R and the intake air temperature sensor are

0.2

connected in series. When the resistance value of the intake air

0.1

temperature sensor changes in accordance with changes in the

intake air temperature, the potential at terminal THA (THAR)

– 20

0

20

40

60

80

100

(- 4)

32

68

104

140

176

212

also changes. Based on this signal, the ECM increases the fuel

Temp. _C (_F)

injection volume to improve the drive ability during cold engine

A67628

operation.

DTC No.

Proceed to

DTC Detection Condition

Trouble Area

Open or short in intake air

P0110

Step 1

temperature sensor circuit for

0.5 seconds

Short in intake air tempera-

F Open or short in intake air temperature sensor circuit

P0112

Step 4

ture sensor circuit for 0.5 se-

F Intake air temperature sensor (built in mass air flow sensor)

conds

F ECM

Open in intake air tempera-

P0113

Step 2

ture sensor circuit for 0.5 se-

conds

HINT:

After confirming DTC P0110, P0112 or P0113, confirm the intake air temperature in the ”DIAGNOSIS / EN-

HANCED OBD II / DATA LIST / ALL” using the hand-held tester or the OBD II scan tool.

Temperature Displayed

Malfunction

-40°C (-40°F)

Open circuit

140°C (284°F) or more

Short circuit

05-75

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

MONITOR DESCRIPTION

The ECM monitors the sensor voltage and uses this value to calculate the intake air temperature. When the

sensor output voltage deviates from the normal operating range, the ECM interprets this as a fault in the IAT

sensor and sets a DTC.

Example:

When the sensor voltage output equal to

-40_C (-40_F) or more than 140_C (284_F).

MONITOR STRATEGY

P0110

Intake air temperature sensor range check (fluttering)

Related DTCs

P0112

Intake air temperature sensor range check (low resistance)

P0113

Intake air temperature sensor range check (high resistance)

Required sensors/components

Intake air temperature sensor

Frequency of operation

Continuous

Duration

0.5 seconds

MIL operation

Immediately

Sequence of operation

None

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the follow-

See ”List of Disable a Monitor” (On page 05-25)

ing DTCs are not present

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

P0110:

Intake air temperature sensor resistance

Less than 98.5 W or more than 156 kW

(Intake air temperature)

(more than 140_C (284_F) or less than -40_C (-40_F)

P0112:

Intake air temperature sensor resistance

Less than 98.5 W

(Intake air temperature)

(more than 140_C (284_F))

P0113:

Intake air temperature sensor resistance

More than 156 kW

(Intake air temperature)

(less than -40_C (-40_F))

COMPONENT OPERATING RANGE

Parameter

Standard Value

Intake air temperature sensor resistance

98.5 W140_C (281_F)) to 156 kW(-40_C (-40_F)

WIRING DIAGRAM

ECM

M1

Intake Air Temp. Sensor

(Mass Air Flow Sensor)

20

4

Y-B

THA

E3

H

F

28

5

BR

BR

E2

J2

J3

E3

Junction

Connector

A84867