Toyota Corolla (2004+). Manual - part 54

05-282

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

7

CHECK HARNESS AND CONNECTOR(CIRCUIT OPENING RELAY - FUEL PUMP,

FUEL PUMP - BODY GROUND)

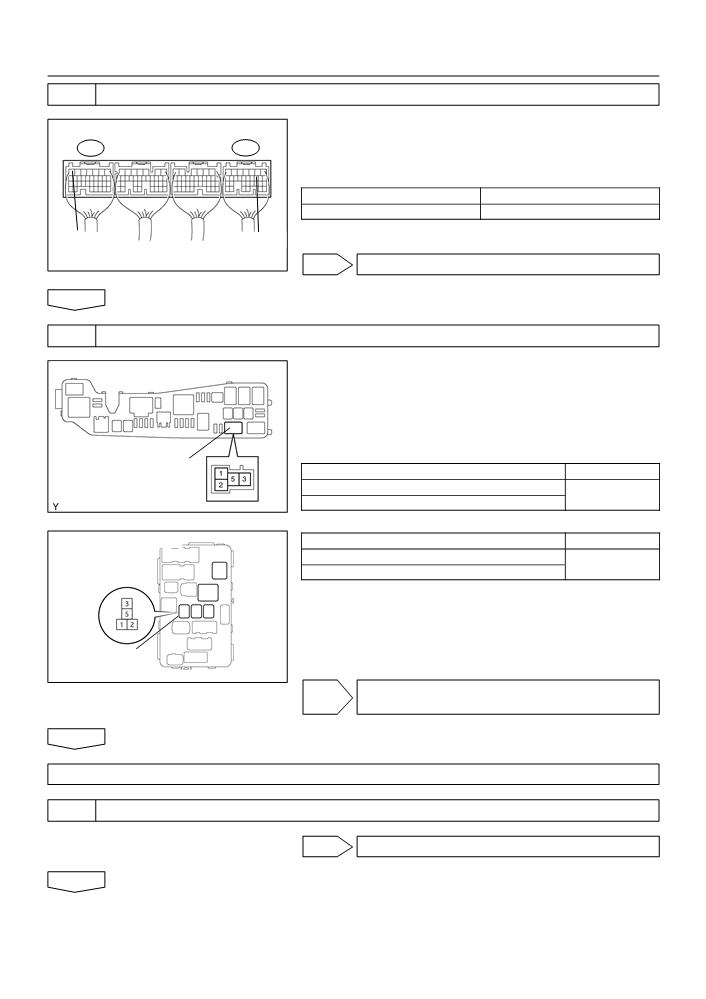

(a) Remove the circuit opening relay from the instrument

Instrument Panel J/B:

panel J/B.

(b) Disconnect the F10 fuel pump connector.

(c)

Check the resistance between the wire harness side con-

nectors.

Standard (Check for open):

Tester Connection

Specified Condition

Circuit Opening

Circuit opening relay (3) - Fuel pump (F10-4)

Below 1 W

Relay

Fuel pump (F10-5) - Body ground

A85429

Standard (Check for short):

Tester Connection

Specified Condition

Wire Harness Side:

Circuit opening relay (3) or Fuel pump (F10-4) - Body ground

10 kW or higher

Fuel Pump Connector

F10

(d) Reconnect the fuel pump connector.

(e) Reinstall the circuit opening relay.

Front View

NG REPAIR OR REPLACE HARNESS OR

A66276

CONNECTOR

OK

REPLACE ECM (See page 10-11)

05-283

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

OBD II scan tool (excluding hand-held tester):

1

CHECK OPERATION OF FUEL PUMP

(a) Turn the ignition switch ON.

(b) Connect between terminals FC and E01 of the ECM con-

E3

E6

nector.

(c)

Check for fuel pressure in the fuel inlet hose when it is

pinched off.

Result: There is pressure in fuel inlet hose.

HINT:

E01 (-)

FC (+)

At this time, you will hear the fuel flowing sound.

ECM Connector

A18294

OK PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN ON PROBLEM SYMPTOMS TABLE

A72879

(See page 05-42)

NG

2

INSPECT ECM POWER SOURCE CIRCUIT (See page 05-273)

NG REPAIR OR REPLACE ECM POWER SOURCE

CIRCUIT

OK

3

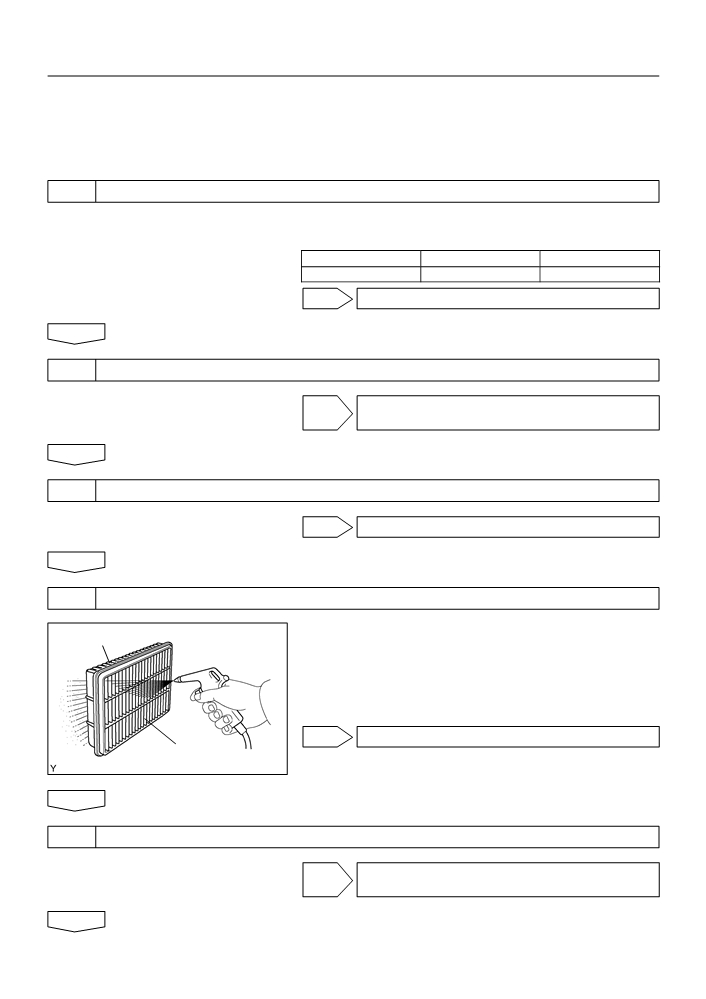

INSPECT CIRCUIT OPENING RELAY

(a) Remove the circuit opening relay from the instrument

panel J/B.

(b) Check for continuity in the circuit opening relay.

Standard:

Tester Connection

Specified Condition

1 - 2

Continuity

No continuity

3 - 5

Continuity

(Apply battery voltage to terminals 1 and 2)

E34090

(c)

Reinstall the circuit opening relay.

NG REPLACE CIRCUIT OPENING RELAY

OK

05-284

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

4

INSPECT ECM(FC VOLTAGE)

(a) Turn the ignition switch ON.

(b) Measure the voltage between the terminals of the E3 and

E3

E6

E6 ECM connectors.

Standard:

Tester Connection

Specified Condition

FC (E6-10) - E01 (E3-7)

9 to 14 V

E01 (-)

FC (+)

ECM Connector

A18294

OK REPLACE ECM (See page 10-11)

NG

5

CHECK HARNESS AND CONNECTOR(EFI RELAY - CIRCUIT OPENING RELAY)

Engine Room R/B:

(a) Remove the EFI relay from the engine room R/B.

(b) Remove the circuit opening relay from the instrument

panel J/B.

(c)

Check the resistance between the wire harness side con-

nectors.

Standard (Check for open):

EFI Relay

Tester Connection

Specified Condition

EFI relay (1) - Circuit opening relay (1)

Below 1 W

A65750

EFI relay (3) - Circuit opening relay (5)

Standard (Check for short):

Instrument Panel J/B:

Tester Connection

Specified Condition

EFI relay (1) or Circuit opening relay (1) - Body ground

10 kW or higher

EFI relay (3) or Circuit opening relay (5) - Body ground

(d) Reinstall the circuit opening relay.

(e) Reinstall the EFI relay.

Circuit Opening

Relay

A85429

NG REPAIR OR REPLACE HARNESS AND

CONNECTOR

OK

REPLACE ECM (See page 10-11)

6

INSPECT FUEL PUMP

NG REPAIR OR REPLACE FUEL PUMP

OK

05-285

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

7

CHECK HARNESS AND CONNECTOR(CIRCUIT OPENING RELAY - FUEL

PUMP,FUEL PUMP - BODY GROUND)

(a) Remove the circuit opening relay from the instrument

Instrument Panel J/B:

panel J/B.

(b) Disconnect the F10 fuel pump connector.

(c)

Check the resistance between the wire harness side con-

nectors.

Standard (Check for open):

Tester Connection

Specified Condition

Circuit Opening

Circuit opening relay (3) - Fuel pump (F10-4)

Below 1 W

Relay

Fuel pump (F10-5) - Body ground

A85429

Standard (Check for short):

Tester Connection

Specified Condition

Wire Harness Side

Circuit opening relay (3) or Fuel pump (F10-4) - Body ground

10 kW or higher

Fuel Pump Connector

F10

(d) Reconnect the fuel pump connector.

(e) Reinstall the circuit opening relay.

Front View

NG REPAIR OR REPLACE HARNESS AND

A66276

CONNECTOR

OK

REPLACE ECM (See page 10-11)

05-13

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05CRJ-02

BASIC INSPECTION

When the malfunction is not confirmed in the DTC check, troubleshooting should be carried out in all the

possible circuits considered as causes of the problem. In many cases, by carrying out the basic engine check

shown in the following flowchart, the location causing the problem can be found quickly and efficiently. There-

fore, using this check is essential in the engine troubleshooting.

1

CHECK BATTERY VOLTAGE

NOTICE:

Carry out this check with the engine stopped and ignition switch OFF.

OK

NG

Voltage

11 V or more

Less than 11 V

NG CHARGE OR REPLACE BATTERY

OK

2

CHECK IF ENGINE WILL CRANK

NG PROCEED TO PROBLEM SYMPTOMS TABLE

ON PAGE 05-42

OK

3

CHECK IF ENGINE STARTS

NG GO TO STEP 7

OK

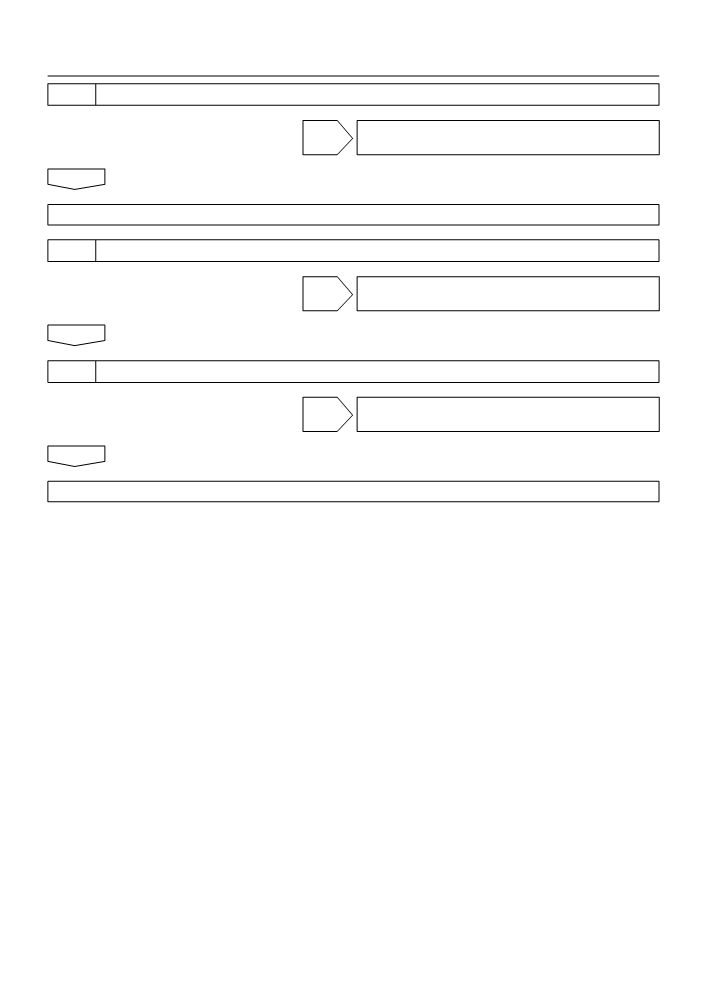

4

CHECK AIR FILTER

(a) Visually check that the air filter is not excessively dirty or

Outside

oily.

NOTICE:

If necessary, clean the filter with compressed air. First blow

from the inside thoroughly, then blow from the outside of

the filter.

NG CLEAN OR REPLACE

Inside

A66289

OK

5

CHECK IDLE SPEED (See page 14-1)

NG PROCEED TO PROBLEM SYMPTOMS TABLE

ON PAGE 05-42

OK

05-14

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

6

CHECK IGNITION TIMING (See page 14-1)

NG PROCEED TO PAGE 14-1 AND CONTINUE TO

TROUBLESHOOT

OK

PROCEED TO PROBLEM SYMPTOMS TABLE ON PAGE 05-42

7

CHECK FUEL PRESSURE (See page 11-5)

NG PROCEED TO PAGE 11-1 AND CONTINUE TO

TROUBLESHOOT

OK

8

CHECK FOR SPARK (See page 18-1)

NG PROCEED TO PAGE 18-1 AND CONTINUE TO

TROUBLESHOOT

OK

PROCEED TO PROBLEM SYMPTOMS TABLE ON PAGE 05-42

05-25

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

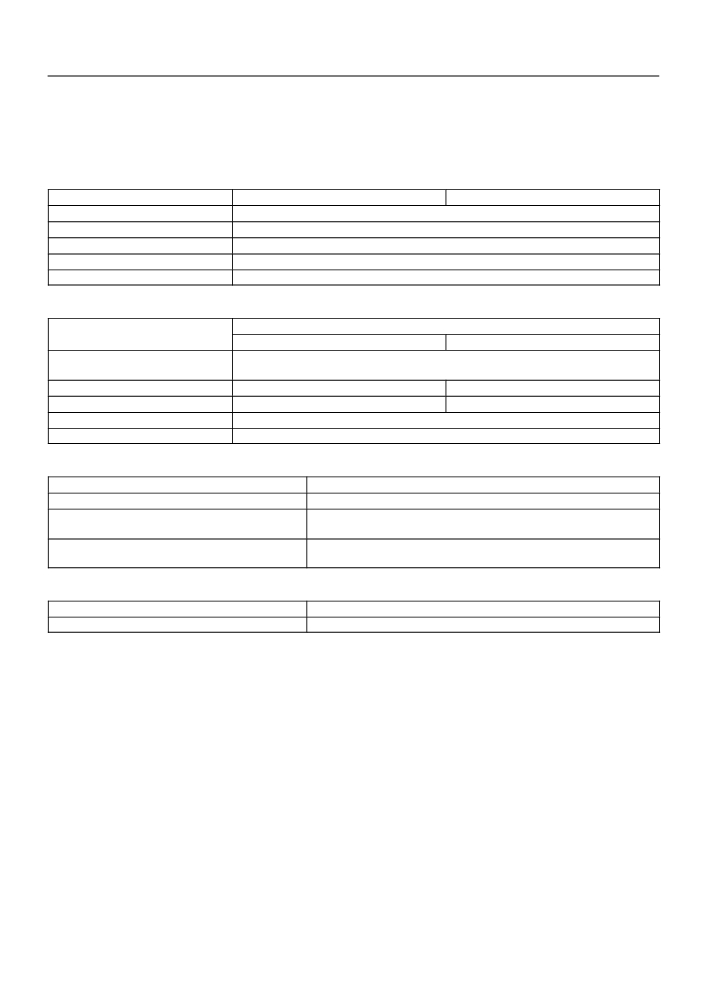

05DIF-01

LIST OF DISABLE A MONITOR

HINT:

This table indicates ECM monitoring status for the items in the upper columns if the DTCs in each line on

the left are being set.

G26588

05-26

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

G26589

05-292

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

059UT-07

MIL CIRCUIT

CIRCUIT DESCRIPTION

The ignition switch provides circuit power and the ECM provides the circuit ground that illuminates the MIL.

MIL operation is checked visually:

It should be illuminated when the ignition is first turned on. If the MIL is off all of the time or on all of the time,

use the procedure below to troubleshoot it. The MIL is used to indicate the ECM’s detection of a vehicle mal-

function. Follow this procedure using the hand-held tester or an OBD II scan tool to determine the cause

of the problem and to check the MIL.

WIRING DIAGRAM

AM2

3

6

B-R

B

IM

IM

ECM

5

11

Instrument

R-Y

E6

W

2

IA4

Panel J/B

I10

Ignition

B-R

Switch

33

1

6

2

Malfunction

Engine

Indicator

MAIN

Room R/B

Lamp

and J/B

1

B-W

1

IA

B

5

IL

32

C9

FL MAIN

Instrument

Combination

Panel J/B

Meter

8

IK

Battery

B-O

A84735

INSPECTION PROCEDURE

HINT:

Troubleshoot each trouble symptom in accordance with the chart below.

MIL remains on

Start inspection from step 1

MIL is not illuminated

Start inspection from step 3

05-293

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

1

CLEAR DTC

(a) Connect the hand-held tester or the OBD II scan tool to the DLC 3.

(b) Turn the ignition switch ON and push the hand-held tester or the OBD II scan tool main switch ON.

(c)

Read the DTC (See page 05-9).

(d) Clear the DTC (See page 05-9).

(e) Check that MIL is not illuminated.

Standard: MIL is not illuminated

OK REPAIR CIRCUIT INDICATED BY OUTPUT

CODE (See page 05-35)

NG

2

CHECK HARNESS AND CONNECTOR(CHECK FOR SHORT IN WIRE HARNESS)

(a) Disconnect the E6 ECM connector.

(b) Turn the ignition switch ON.

E6

(c)

Check that MIL is not illuminated.

Standard: MIL is not illuminated

(d) Reconnect the ECM connector.

ECM Connector

A65748

OK REPLACE ECM (See page 10-11)

NG

CHECK AND REPAIR HARNESS AND CONNECTOR (COMBINATION METER - ECM)

3

CHECK THAT MIL IS ILLUMINATED

(a) Check that MIL is illuminated when turning the ignition switch ON.

Standard: MIL is illuminated

OK SYSTEM OK

NG

4

INSPECT COMBINATION METER ASSY (MIL CIRCUIT)

(a) See the combination meter troubleshooting on page (See page 05-638).

NG REPAIR OR REPLACE BULB OR COMBINATION

METER ASSEMBLY

OK

CHECK AND REPAIR HARNESS AND CONNECTOR (COMBINATION METER - ECM)

05-44

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05AIH-06

DTC

P0010

CAMSHAFT POSITION ”A” ACTUATOR

CIRCUIT (BANK 1)

CIRCUIT DESCRIPTION

The Variable Valve Timing (VVT) system includes the ECM, the Oil Control Valve (OCV) and the VVT control-

ler. The ECM sends a target ”duty-cycle” control signal to the OCV. This control signal, applied to the OCV,

regulates the oil pressure supplied to the VVT controller. Camshaft timing control is performed based on en-

gine operation conditions such as the intake air volume, throttle position and engine coolant temperature.

The ECM controls the OCV, based on the signals output from the sensors. The VVT controller regulates the

intake camshaft angle using oil pressure through the OCV. As result, the relative position between the cam-

shaft and the crankshaft is optimized, and the engine torque improves, fuel economy improves, and exhaust

emissions decrease under overall driving conditions. Also, the ECM detects the actual valve timing using

signals from the camshaft position sensor and the crankshaft position sensor, and performs the feedback

control. This is how target valve timing is verified by the ECM.

ECM

Crankshaft Position Sensor

Camshaft Timing

Mass Air Flow Sensor

Target Valve Timing

Oil Control

Valve (OCV)

Throttle Position Sensor

Feedback

Duty Control

Engine Coolant Temp. Sensor

Correction

Vehicle Speed Signal

Actual Valve Timing

Camshaft Position Sensor

A71007

DTC No.

DTC Detection Condition

Trouble Area

F Open or short in oil control valve circuit

P0010

Open or short in oil control valve circuit

F Oil control valve

F ECM

05-45

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

MONITOR DESCRIPTION

After the ECM sends the ”target” duty-cycle signal to the OCV, the ECM monitors the OCV current to estab-

lish an ”actual” duty-cycle. The ECM detects a malfunction and sets a DTC when the actual duty-cycle ratio

varies from the target duty-cycle ratio.

MONITOR STRATEGY

Related DTCs

P0010

VVT oil control valve bank 1 range check

Required sensors/components

OCV

Frequency of operation

Continuous

Duration

1 seconds

MIL operation

Immediately

Sequence of operation

None

TYPICAL ENABLING CONDITIONS

Specification

Item

Minimum

Maximum

The monitor will run whenever the follow-

See ”List of Disable a Monitor” (On page 05-25)

ing DTCs are not present

Battery voltage

11 V

13 V

Target duty ratio

-

70 %

Starter

OFF

Current cut status

Not cut

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

One of the following condition is met:

(a) or (b)

Output duty ratio is 100 % (always ON)

(a) Output signal duty for OCV

despite the target duty ratio is less than 70 %

Output duty is 3 % or less

(b) Output signal duty for OCV

despite the ECM supplying the current to the OCV

COMPONENT OPERATING RANGE

Parameter

Standard Value

Output signal duty for OCV

Between 3 % and 100 %

05-46

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

WIRING DIAGRAM

ECM

C2

Camshaft Timing Oil

Control Valve

15

1

Y

E3

OCV+

14

2

B-Y

E3

OCV-

A59779

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the hand-held tester or the OBD II scan tool. Freeze frame data records the

engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether

the vehicle was running or stopped, the engine was warmed up or not, the air-fuel ratio was lean or rich,

etc. at the time of the malfunction.

Hand-held tester:

1

PERFORM ACTIVE TEST BY HAND-HELD TESTER(OPERATE OCV)

(a) Connect the hand-held tester to the DLC3.

(b) Start the engine and warm it up.

(c)

Turn the ignition switch ON and push the hand-held tester main switch ON.

(d) Select the item ”DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / VVT CTRL B1”.

(e) Check the engine speed when operating the Oil control valve (OCV) by the hand-held tester.

Standard:

Tester Operation

Specified Condition

OCV is OFF

Normal engine speed

OCV is ON

Rough idle or engine stall

OK CHECK FOR INTERMITTENT PROBLEMS

(See page 05-41)

NG

2

INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSY(OCV)

(See page 10-2)

NG REPLACE CAMSHAFT TIMING OIL CONTROL

VALVE ASSY

OK

05-47

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

3

INSPECT ECM(OCV SIGNAL)

(a) Inspection using the oscilloscope.

(b) During idling, check the waveform between the terminals

E3

of the E3 ECM connector.

Standard:

Tester Connection

Specified Condition

OCV+ (E3-15) - OCV- (E3-14)

Correct waveform is as shown

OCV + OCV-

OCV Signal Waveform

5 V/

Division

GND

1 msec./Division

A79111

NG REPLACE ECM (See page 10-11)

OK

4

CHECK HARNESS AND CONNECTOR(CAMSHAFT TIMING OIL CONTROL VALVE

(OCV) - ECM)

(a) Disconnect the C2 camshaft timing oil control valve con-

Wire Harness Side:

Camshaft Timing Oil Control Valve

nector.

C2

Connector

(b) Disconnect the E3 ECM connector.

(c)

Check the resistance between the wire harness side con-

nectors.

Standard (Check for open):

Tester Connection

Specified Condition

Oil control valve (C2-1) - OCV+ (E3-15)

Front View

Below 1 W

A54386

Oil control valve (C2-2) - OCV- (E3-14)

Standard (Check for short):

Tester Connection

Specified Condition

Oil control valve (C2-1) or OCV+ (E3-15) - Body ground

10 kW or higher

E3

Oil control valve (C2-2) or OCV- (E3-14) - Body ground

(d) Reconnect the camshaft timing oil control valve connec-

tor.

(e) Reconnect the ECM connector.

NG REPAIR OR REPLACE HARNESS OR

OCV+ OCV-

CONNECTOR

ECM Connector

A65743

OK

CHECK FOR INTERMITTENT PROBLEMS (See page 05-41 )

05-48

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

OBDII scan tool (excluding hand-held tester):

1

INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSY(OPERATE OCV)

(a) Disconnect the C2 camshaft timing oil control valve con-

Component Side:

nector.

Camshaft Timing Oil Control Valve

(b) Apply positive battery voltage between the terminals of

C2

the camshaft timing oil control valve.

(c)

Check the engine speed.

Standard:

Engine speed is rough idle or engine is stalled.

(-)

(+)

(d) Reconnect the camshaft timing oil control valve connec-

Front View

A76968

tor.

NG REPLACE CAMSHAFT TIMING OIL CONTROL

VALVE ASSY

OK

2

INSPECT ECM(OCV SIGNAL)

(a) Inspection using the oscilloscope.

(b) During idling, check the waveform between the terminals

E3

of the E3 ECM connector.

Standard:

Tester Connection

Specified Condition

OCV+ (E3-15) - OCV- (E3-14)

Correct waveform is as shown

OCV + OCV-

OCV Signal Waveform

5 V/

Division

GND

1 msec./Division

A79111

NG REPLACE ECM (See page 10-11)

OK