Toyota Corolla (2004+). Manual - part 53

05-37

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

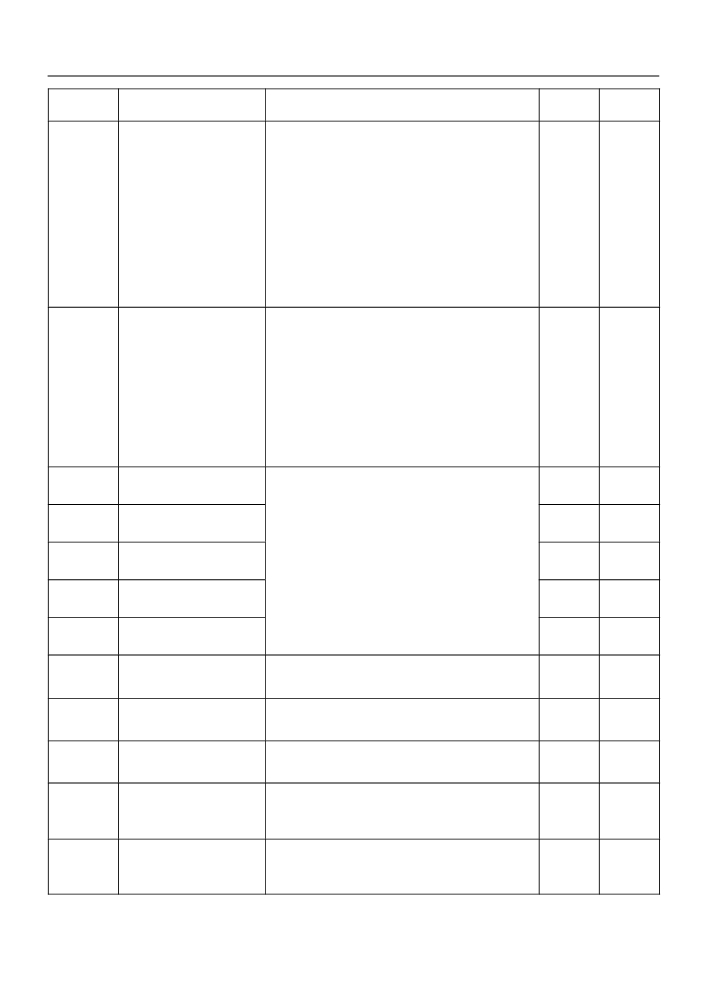

DTC No.

Detection Item

Trouble Area

MIL*1

Memory

(See Page)

F Air induction system

F Injector blockage

F Mass air flow sensor

F Engine coolant temperature sensor

F Fuel pressure

F Gas leakage in exhaust system

P0171

F Open or short in heated oxygen sensor (bank 1, sensor 1)

System too Lean (Bank 1)

_

_

(05-136)

circuit

F Heated oxygen sensor (bank 1, sensor 1)

F Heated oxygen sensor heater (bank 1, sensor 1)

F EFI relay

F PCV valve and hose

F PCV hose connection

F ECM

F Injector leak, blockage

F Mass air flow sensor

F Engine coolant temperature sensor

F Ignition system

F Fuel pressure

P0172

F Gas leakage in exhaust system

System too Rich (Bank 1)

_

_

(05-136)

F Open or short in heated oxygen sensor (bank 1, sensor 1)

circuit

F Heated oxygen sensor (bank 1, sensor 1)

F Heated oxygen sensor heater (bank 1, sensor 1)

F EFI relay

F ECM

P0300

Random/Multiple Cylinder Misfire

F Open or short in engine wire

_*2

_

(05-149)

Detected

F Connector connection

F Vacuum hose connection

P0301

F Ignition system

Cylinder 1 Misfire Detected

_*2

_

(05-149)

F Injector

F Fuel pressure

P0302

F Mass air flow sensor

Cylinder 2 Misfire Detected

_*2

_

(05-149)

F Engine coolant temperature sensor

F Compression pressure

P0303

F Valve clearance

Cylinder 3 Misfire Detected

_*2

_

(05-149)

F Valve timing

F PCV hose connection

P0304

Cylinder 4 Misfire Detected

F PCV hose

_*2

_

(05-149)

F ECM

F Open or short in knock sensor circuit

P0325

Knock Sensor 1 Circuit (Bank 1

F Knock sensor (under-torqued or loose)

_

_

(05-163)

or Single Sensor)

F ECM

F Open or short in knock sensor circuit

P0327

Knock Sensor 1 Circuit Low In-

F Knock sensor (under-torqued or loose)

_

_

(05-163)

put (Bank 1 or Single Sensor)

F ECM

F Open or short in knock sensor circuit

P0328

Knock Sensor 1 Circuit High In-

F Knock sensor (under-torqued or loose)

_

_

(05-163)

put (Bank 1 or Single Sensor)

F ECM

F Open or short in crankshaft position sensor circuit

P0335

Crankshaft Position Sensor ”A”

F Crankshaft position sensor

_

_

(05-168)

Circuit

F Signal plate (crankshaft)

F ECM

F Open or short in crankshaft position sensor circuit

P0339

Crankshaft Position Sensor ”A”

F Crankshaft position sensor

_

(05-168)

Circuit Intermittent

F Signal plate (crankshaft)

F ECM

05-38

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

DTC No.

Detection Item

Trouble Area

MIL*1

Memory

(See Page)

F Open or short in camshaft position sensor circuit

F Camshaft position sensor

P0340

Camshaft Position Sensor ”A”

F Camshaft timing pulley

_

_

(05-173)

Circuit (Bank 1 or Single Sensor)

F Timing chain has jumped a tooth

F ECM

F Open or short in camshaft position sensor circuit

Camshaft Position Sensor ”A”

F Camshaft position sensor

P0341

Circuit Range/Performance

F Camshaft timing pulley

_

_

(05-173)

(Bank 1 or Single Sensor)

F Timing chain has jumped a tooth

F ECM

P0351*3

Ignition Coil ”A” Primary/Second-

_

_

(05-177)

ary Circuit

F Ignition system

P0352*3

Ignition Coil ”B” Primary/Second-

F Open or short in IGF or IGT circuit from ignition coil with igniter

_

_

(05-177)

ary Circuit

to ECM (ignition coil circuit 1 through 4)

P0353*3

Ignition Coil ”C” Primary/Second-

F Ignition coil with igniter (ignition coil circuit 1 through 4)

_

_

(05-177)

ary Circuit

F ECM

P0354*3

Ignition Coil ”D” Primary/Second-

_

_

(05-177)

ary Circuit

F Gas leakage in exhaust system

P0420

Catalyst System Efficiency Be-

F Heated oxygen sensor (bank 1 sensor 1, 2)

_

_

(05-186)

low Threshold (Bank 1)

F Three-way catalytic converter

F Fuel tank cap incorrectly installed

F Fuel tank cap cracked or damaged

F Vacuum hose cracks, blocked, damaged or disconnected ((1),

Evaporative Emission Control

P0441

(2), (3), (4), (5), (6), (7), (8), (9), (10) and (11) in Fig. 1)

System

_

_

(05-193)

F Open or short in vapor pressure sensor circuit

Incorrect Purge Flow

F Vapor pressure sensor

F Open or short in VSV circuit for EVAP

F VSV for EVAP

F Open or short in VSV circuit for CCV

F VSV for CCV

F Open or short in VSV circuit for pressure switching valve

Evaporative Emission Control

P0442

F VSV for pressure switching valve

System Leak detected (small

_

_

(05-218)

F Fuel tank cracked, or damaged

leak)

F Charcoal canister cracked, or damaged

F Fuel tank over fill check valve cracked damaged

F ECM

P0446

Evaporative Emission Control

F Same as DTC No. P0441

_

_

(05-193)

System Vent Control Circuit

Evaporative Emission Control

P0451

System Pressure Sensor Range/

_

_

(05-242)

Performance

Evaporative Emission Control

F Open or short in vapor pressure sensor circuit

P0452

System Pressure Sensor/Switch

F Vapor pressure sensor

_

_

(05-242)

Low Input

F ECM

Evaporative Emission Control

P0453

System Pressure Sensor/Switch

_

_

(05-242)

High Input

Evaporative Emission Control

P0456

System Leak Detected (very

F Same as DTC No. P0442

_

_

(05-218)

small leak)

F Open or short in speed sensor circuit

F Speed sensor

P0500

Vehicle Speed Sensor ”A”

F Combination meter

_

_

(05-247)

F ECM

F Stability control ECU

05-39

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

DTC No.

Detection Item

Trouble Area

MIL*1

Memory

(See Page)

F Open or short in idle speed control (ISC) valve circuit

P0505

Idle Air Control System

F Idle speed control (ISC) valve is stuck or closed

_

_

(05-251)

F A/C switch circuit

F Air induction system

P0511

Idle Air Control Circuit

F PCV valve and hose

_

_

(05-251)

F ECM

P0560

F Open in back up power source circuit

System Voltage

_

_

(05-260)

F ECM

P0606

ECM/PCM Processor

F ECM

_

_

(05-264)

F Short in Park/Neutral position switch circuit (A/T)

P0617

F Park/Neutral position switch (A/T)

Starter Relay Circuit High

_

_

(05-265)

F Clutch start switch (M/T)

F ECM

P0705

Transmission Range Sensor Cir-

_

_

(05-379)

cuit Malfunction (PRNDL Input)

P0724

Brake Switch ”B” Circuit High

_

_

(05-384)

Torque Converter Clutch Sole-

P0741

noid Performance (Shift Solenoid

_

_

(05-386)

Valve SL)

P0751

Shift Solenoid ”A” Performance

_

_

(05-389)

(Shift Solenoid Valve S1)

P0756

Shift Solenoid ”B” Performance

_

_

(05-394)

(Shift Solenoid Valve S2)

F Electronic controlled automatic transmission (ECT)

P0850

Park/Neutral Switch Input Circuit

_

_

(05-379)

P0973

Shift Solenoid ”A” Control Circuit

_

_

(05-402)

Low (Shift Solenoid Valve S1)

P0974

Shift Solenoid ”A” Control Circuit

_

_

(05-402)

High (Shift Solenoid Valve S1)

P0976

Shift Solenoid ”B” Control Circuit

_

_

(05-406)

Low (Shift Solenoid Valve S1)

P0977

Shift Solenoid ”B” Control Circuit

_

_

(05-406)

High (Shift Solenoid Valve S1)

F Open or short in heated oxygen sensor (bank 1 sensor 1)

P2195

Oxygen Sensor Signal Stuck

circuit

_

_

(05-101)

Lean (Bank 1 Sensor 1)

F Heated oxygen sensor (bank 1 sensor 1)

F Heated oxygen sensor heater (bank 1 sensor 1)

F EFI relay

F Air induction system

P2196

Oxygen Sensor Signal Stuck

F Fuel pressure

_

_

(05-101)

Rich (Bank 1 Sensor 1)

F Injector

F ECM

P2716

Pressure Control Solenoid ”D”

_

_

(05-409)

Electrical

P2769

DSL Solenoid Circuit Low

F Electronic controlled automatic transmission (ECT)

_

_

(05-413)

(Shift Solenoid Valve DSL)

P2770

DSL Solenoid Circuit High

_

_

(05-413)

(Shift Solenoid Valve DSL)

*1: ”_” ... MIL is illuminated, ”” ... MIL is not illuminated.

*2: MIL is illuminated or blinks

*3: This DTC is indicate a malfunction related to primary circuit.

05-9

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05CRH-02

DTC CHECK/CLEAR

NOTICE:

F

If there is no DTC in the normal mode, check the pend-

ing fault code using the Continuous Test Results

function (Mode 7 for SAE J1979) on the OBD II scan

tool or the hand-held tester.

F

Hand-held tester only:

When the diagnosis system is switched from the nor-

mal mode to the check mode, all the DTCs and freeze

frame data recorded in the normal mode will be

erased. So before switching modes, always check the

DTCs and freeze frame data, and then write them

down.

1.

CHECK DTC (Using the OBD II scan tool or hand-held

Hand-held Tester

tester)

(a)

Connect the OBD II scan tool or hand-held tester to the

DLC3.

(b)

Turn the ignition switch ON.

(c)

Use the OBD II scan tool or the hand-held tester to check

the DTCs and freeze frame data and then write them

down. If you need help with the OBD II scan tool, refer to

DCL3

A79121

the scan tool’s manual book.

If there is no DTC in the normal mode, check the pending

fault code using the Continuous Test Results function on

the OBD II scan tool or the hand-held tester.

(d)

See page 05-35 to confirm the details of the DTCs.

NOTICE:

F

When simulating a symptom with the OBD II scan tool

(excluding hand-held tester) to check the DTCs, use

the normal mode. For code on the DTC chart subject

to the ”2 trip detection logic”, perform either of the fol-

lowing actions.

F

Turn the ignition switch OFF after the symptom is

simulated once. Then repeat the simulation process

again. When the problem has been simulated twice,

the MIL lights up and the DTCs are recorded in the

ECM.

F

Check the pending fault code using the Continuous

Test Results function on the OBD II scan tool.

2.

CLEAR DTC (Using the OBD II scan tool or hand-held

tester)

(a) Connect the OBD II scan tool or the hand-held tester to

the DLC3.

(b) Turn the ignition switch ON.

05-10

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

(c)

Operate the OBD II scan tool or the hand-held tester to

erase the codes. All the DTCs and freeze frame data will

be erased. (See the OBD II scan tool’s manual book for

operating manuals.)

3.

CLEAR DTC (Not using the OBD II scan tool or hand-

held tester)

(a) Disconnect the battery terminal or remove the EFI fuse

from the engine room R/B for more than 60 seconds.

05-273

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

05CRY-02

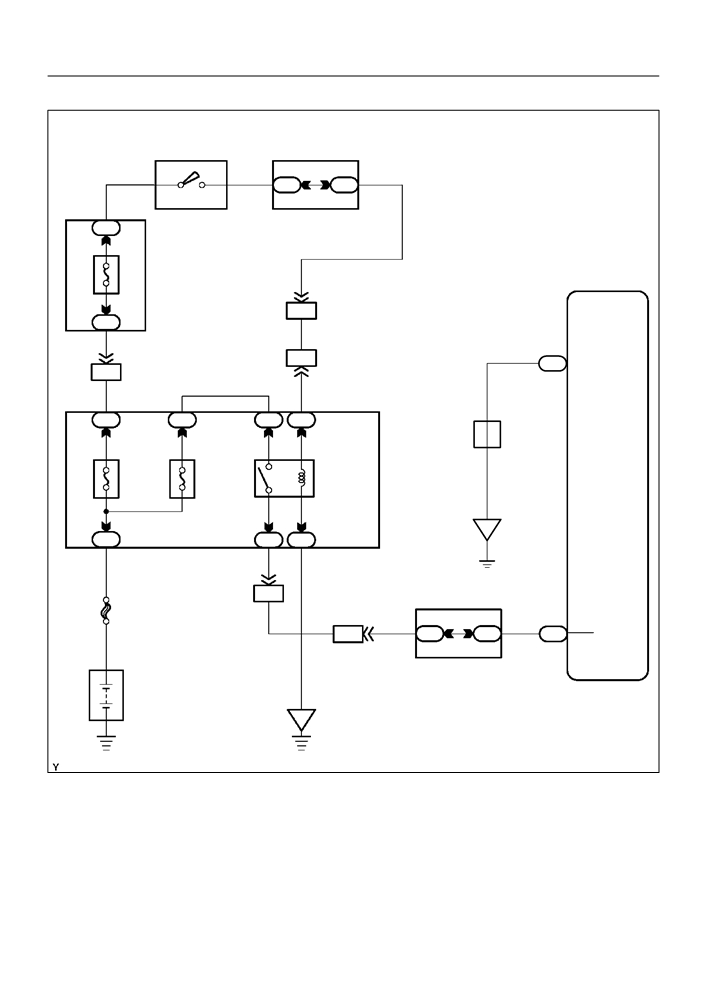

ECM POWER SOURCE CIRCUIT

CIRCUIT DESCRIPTION

When the ignition switch is turned ON, battery positive voltage is applied to the coil which closes the contacts

of the EFI main relay (Marked: EFI) and supplies power to terminal +B of the ECM.

This signal causes current to flow to the coil, closing the contacts of the EFI relay and supplying power to

terminal +B of the ECM.

If the ignition switch is turned off, the ECM continues to switch on the EFI relay for a maximum of 2 seconds

for the initial setting of the ISC valve.

05-274

DIAGNOSTICS

-

SFI SYSTEM (April, 2003)

WIRING DIAGRAM

Instrument

Panel J/B

5

12

5

6

IL

IC

AM2 IG2

B-W

B

Ignition

B-W

6

IM

Switch

AM2

Instrument

ECM

Panel J/B

EA1 10

3

IM

B-W

B-R

7

EA1 3

BR

E4

E1

IA4

2

R-W

B-W

B-R

A

1

1

1

1

J4 J/B

2

2

5

1

A

EFI

Engine Room

MAIN

EFI

Relay

R/B and J/B

BR

3

2

1

1

EB

1

1A

1

1

B

B

EA1

9

W-B

FL

MAIN

6

1

3

1

B

B

B

+B

II1

4B

4B

E6

Center J/B

Battery

ED

A84935

05-275

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

INSPECTION PROCEDURE

1

INSPECT ECM(+B VOLTAGE)

(a) Turn the ignition switch ON.

(b) Measure the voltage between the terminals of the E4 and

E4

E6

E6 ECM connectors.

Standard:

Tester Connection

Specified Condition

+B (E6-1) - E1 (E4-7)

8 to 14 V

E1 (-)

+B (+)

OK REPLACE ECM (See page 10-11)

ECM Connecter

A18294

NG

2

CHECK HARNESS AND CONNECTOR(ECM - BODY GROUND)

(a) Disconnect the E4 ECM connector.

(b) Check the resistance between the wire harness side con-

E4

nectors.

Standard (Check for open):

Tester Connection

Specified Condition

E1 (E4-7) - Body ground

Below 1 W

(c)

Reconnect the ECM connector.

E1

ECM Connector

A65745

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

3

INSPECT IGNITION OR STARTER SWITCH ASSY

(a) Disconnect the I10 ignition switch connector.

Component Side:

Ignition Switch

(b) Check for continuity between the connector terminals

shown in the chart below.

I10

Switch Position

Tester Connection

Specified Condition

LOCK

All Terminals

No continuity

ACC

1-3

Continuity

ON

1-2, 1-3, 2-3, 5-6

Continuity

START

1-2, 4-5, 4-6, 5-6

Continuity

Front View

B50489

(c)

Reconnect the ignition switch connector.

NG REPLACE IGNITION OR STARTER SWITCH

ASSY

OK

05-276

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

4

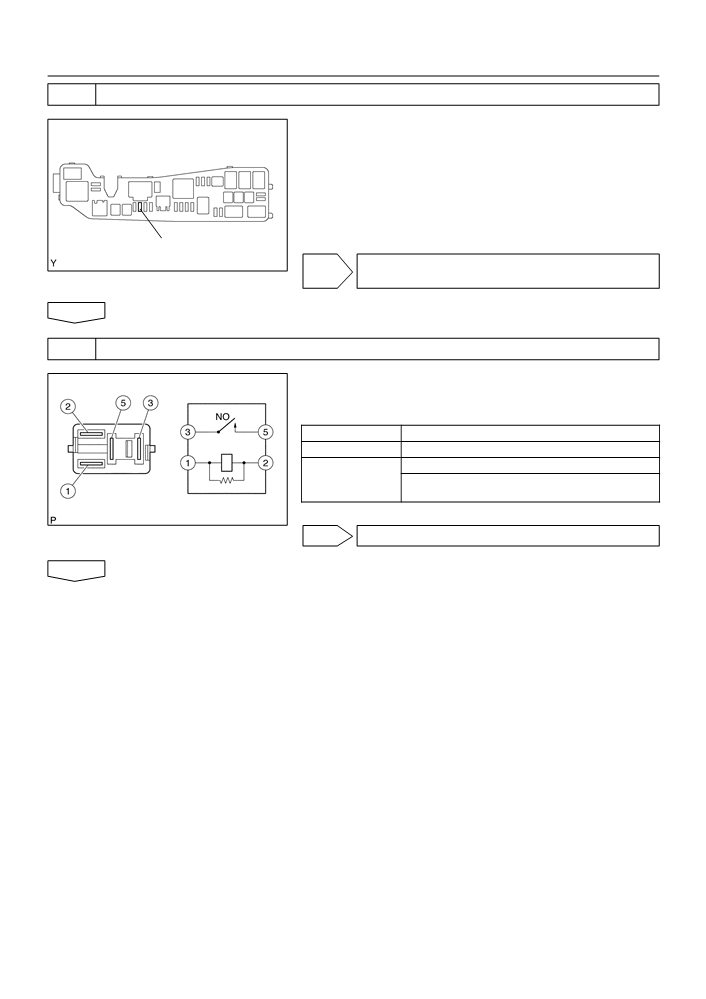

CHECK FUSE(EFI FUSE)

(a) Remove the EFI fuse from the engine room R/B.

Engine Room R/B:

(b) Check for continuity in the EFI fuse.

Standard: Continuity

(c)

Reinstall the EFI fuse.

EFI fuse

A65754

NG CHECK FOR SHORT IN ALL HARNESSES AND

COMPONENTS CONNECTED FUSE

OK

5

INSPECT EFI RELAY

(a) Remove the EFI relay from the engine room R/B.

(b) Check for continuity in the circuit EFI relay.

Standard:

Tester Connection

Specified Condition

1 - 2

Continuity

No continuity

3 - 5

Continuity

(Apply battery voltage to terminals 1 and 2)

(c)

Reinstall the EFI fuse.

E34090

NG REPLACE EFI RELAY

OK

05-277

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

6

CHECK HARNESS AND CONNECTOR(EFI RELAY - ECM, EFI RELAY - BODY

GROUND)

(a)

Check the harness and connector between the EFI relay

Engine Room R/B:

and ECM.

(1)

Remove the EFI relay from the engine room R/B.

(2)

Disconnect the E6 ECM connector.

(3)

Check the resistance between the wire harness

side connectors.

Standard (Check for open):

Tester Connection

Specified Condition

A65750

EFI relay (3) - +B (E6-1)

Below 1 W

Standard (Check for short):

Tester Connection

Specified Condition

EFI relay (3) or +B (E6-1) - Body ground

10 kW or higher

E6

(4)

Reconnect the ECM connector.

(5)

Reinstall the EFI relay.

(b)

Check the harness and connector between the EFI relay

and body ground.

(1)

Remove the EFI relay from the engine room R/B.

+B

(2)

Check the resistance between the wire harness

ECM Connector

A65748

side connector and body ground.

Standard (Check for open):

Tester Connection

Specified Condition

EFI relay (2) - Body ground

Below 1 W

(3)

Reinstall the EFI relay.

OK REPAIR OR REPLACE HARNESS OR

CONNECTOR

NG

CHECK AND REPAIR HARNESS AND CONNECTOR (TERMINAL +B OF ECM - BATTERY POS-

ITIVE TERMINAL)

05-40

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05CRL-02

FAIL-SAFE CHART

If any of the following codes is recorded, the ECM enters the fail-safe mode.

DTC No.

Fail-Safe Operation

Fail-Safe Deactivation Conditions

P0031

P0032

The heater circuit in which the abnormality is detected is

Ignition switch OFF

P0037

turned off

P0038

P0100

Ignition timing is calculated from engine speed and a throttle

P0102

”Pass” condition detected.

angle

P0103

P0110

P0112

Intake air temperature is fixed at 20°C (68°F)

”Pass” condition detected.

P0113

P0115

P0117

Engine coolant temperature is fixed at 80°C (176°F)

”Pass” condition detected.

P0118

P0120

P0122

Fuel cut intermittently

”Pass” condition detected and ignition switch OFF

P0123

P0121

Fuel cut intermittently

”Pass” condition detected and ignition switch OFF

P0325

P0327

Max. ignition timing retardation

Ignition switch OFF

P0328

P0351

P0352

Fuel cut

”Pass” condition detected.

P0353

P0354

05-278

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

05DIT-01

FUEL PUMP CONTROL CIRCUIT

CIRCUIT DESCRIPTION

In the diagram below, when the engine is cranked, current flows from terminal ST2 of the ignition switch to

the starter relay coil and also current flows to terminal STA of the ECM (STA signal).

When the STA signal and NE signal are input to the ECM, Tr is turned ON, current flows to the coil of the

circuit opening relay, the relay switches on, power is supplied to the fuel pump and the fuel pump operates.

While the NE signal is generated (engine running), the ECM keeps Tr ON (circuit opening relay ON) and the

fuel pump also keeps operating.

Fuel Pump

EFI Relay

C/OPN Relay

ECM

EFI

FC

Tr

Ignition Switch

AM2

ST2

From

NE

Crankshaft Position Sensor

Clutch Start Switch*1

Park/Neutral position Switch*2

STA

ST Relay

Starter

Battery

*1: M/T

*2: A/T

A84734

05-279

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

WIRING DIAGRAM

Instrument Panel J/B

ECM

From Terminal

5

1

10

B-W

1

2

G-R

FC

6 of Ignition

IL

IG

E6

Switch

C/OPEN

4

Relay

19

From Terminal

B

B-R

IG

ID

3 of EFI Relay

5

3

F10

4

Fuel

Pump

5

W-B

BH

A84936

INSPECTION PROCEDURE

Hand-held tester:

1

PERFORM ACTIVE TEST BY HAND-HELD TESTER(OPERATION OF CIRCUIT

OPENING RELAY)

(a) Connect the hand-held tester to the DLC3.

(b) Turn the ignition switch ON and push the hand-held tester main switch ON.

(c)

Select the item ”DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / FUEL PUMP / SPD”.

(d) Check the relay operation while operating it with the hand-held tester.

Standard: Operating noise can be heard from the relay.

OK Go to step 6

NG

2

INSPECT ECM POWER SOURCE CIRCUIT (See page 05-273)

NG REPAIR OR REPLACE POWER SOURCE

CIRCUIT

OK

05-280

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

3

INSPECT CIRCUIT OPENING RELAY

(a) Remove the circuit opening relay from the instrument

panel J/B.

(b) Check for continuity in the circuit opening relay.

Standard:

Tester Connection

Specified Condition

1 - 2

Continuity

No continuity

3 - 5

Continuity

(Apply battery voltage to terminals 1 and 2)

E34090

(c)

Reinstall the circuit opening relay.

NG REPLACE CIRCUIT OPENING RELAY

OK

4

INSPECT ECM(FC VOLTAGE)

(a) Turn the ignition switch ON.

(b) Measure the voltage between the terminals of the E3 and

E3

E6

E6 ECM connectors.

Standard:

Tester Connection

Specified Condition

FC (E6-10) - E01 (E3-7)

9 to 14 V

E01 (-)

FC (+)

OK REPLACE ECM (See page 10-11)

ECM Connector

A18294

NG

05-281

DIAGNOSTICS

- SFI SYSTEM (April, 2003)

5

CHECK HARNESS AND CONNECTOR(EFI RELAY - CIRCUIT OPENING RELAY)

Engine Room R/B

(a) Remove the EFI relay from the engine room R/B.

(b) Remove the circuit opening relay from the instrument

panel J/B.

(c)

Check the resistance between the wire harness side con-

nectors.

Standard (Check for open):

EFI Relay

Tester Connection

Specified Condition

EFI relay (1) - Circuit opening relay (1)

Below 1 W

A65750

EFI relay (3) - Circuit opening relay (5)

Standard (Check for short):

Instrument Panel J/B:

Tester Connection

Specified Condition

EFI relay (1) or Circuit opening relay (1) - Body ground

10 kW or higher

EFI relay (3) or Circuit opening relay (5) - Body ground

(d) Reinstall the circuit opening relay.

(e) Reinstall the EFI relay.

Circuit Opening

Relay

A85429

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

REPLACE ECM (See page 10-11)

6

INSPECT FUEL PUMP (See page 11-7)

NG REPAIR OR REPLACE FUEL PUMP

(See page 11-16)

OK