SsangYong Rexton. Service manual - part 314

M162 ENGINE MECHANICAL 1B1-59

SSANGYONG Y200

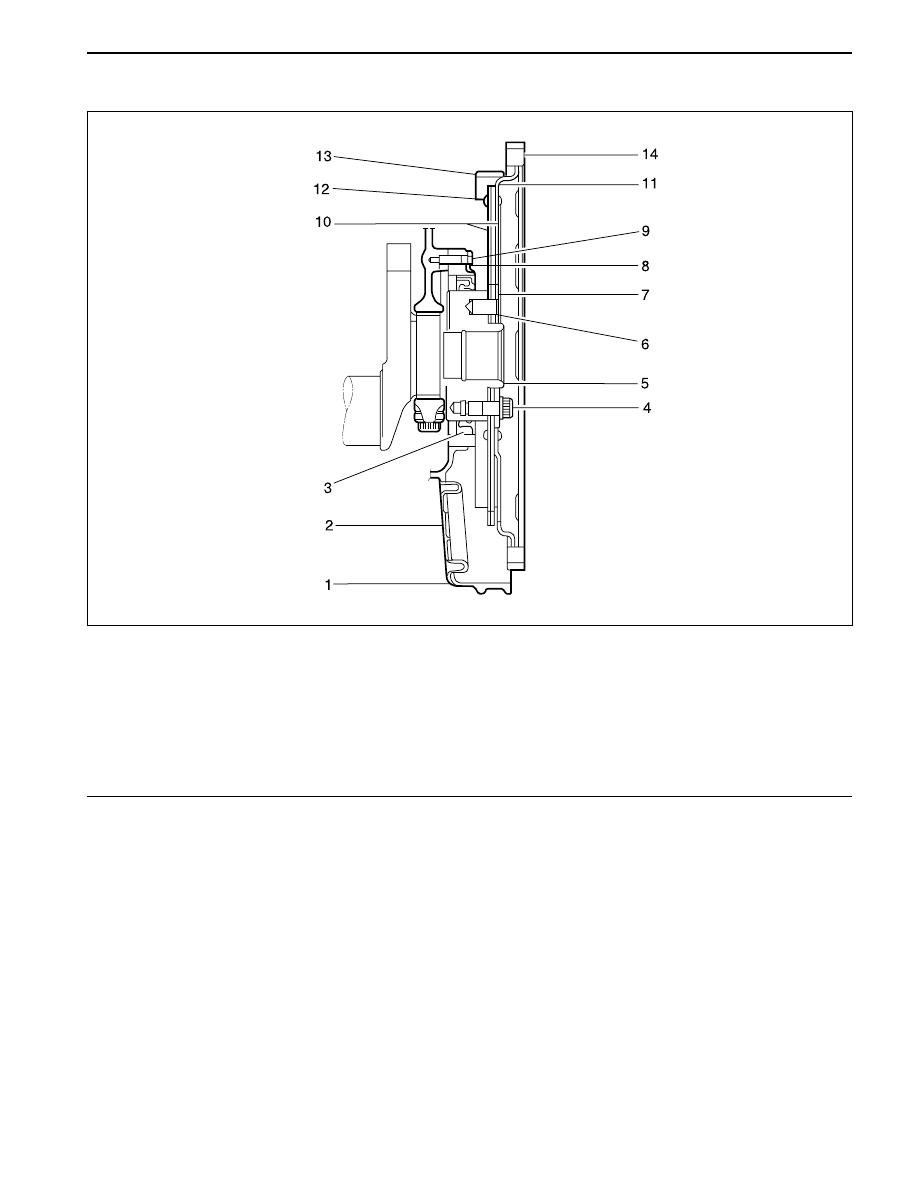

Sectional View

1 Oil Pan

2 Cover

3 Crankshaft Front Seal

4 Flywheel Mounting Bolt

5 Crankshaft

6 Dowel Pin

7 Washer (thickness = 3.5 mm)

YAD1B830

8 Washer

9 Bolt

10 Front Drive Plate

11 Rear Drive Plate

12 Rivet

13 Segment

14 Ring Gear