SsangYong Rexton. Service manual - part 313

M162 ENGINE MECHANICAL 1B1-55

SSANGYONG Y200

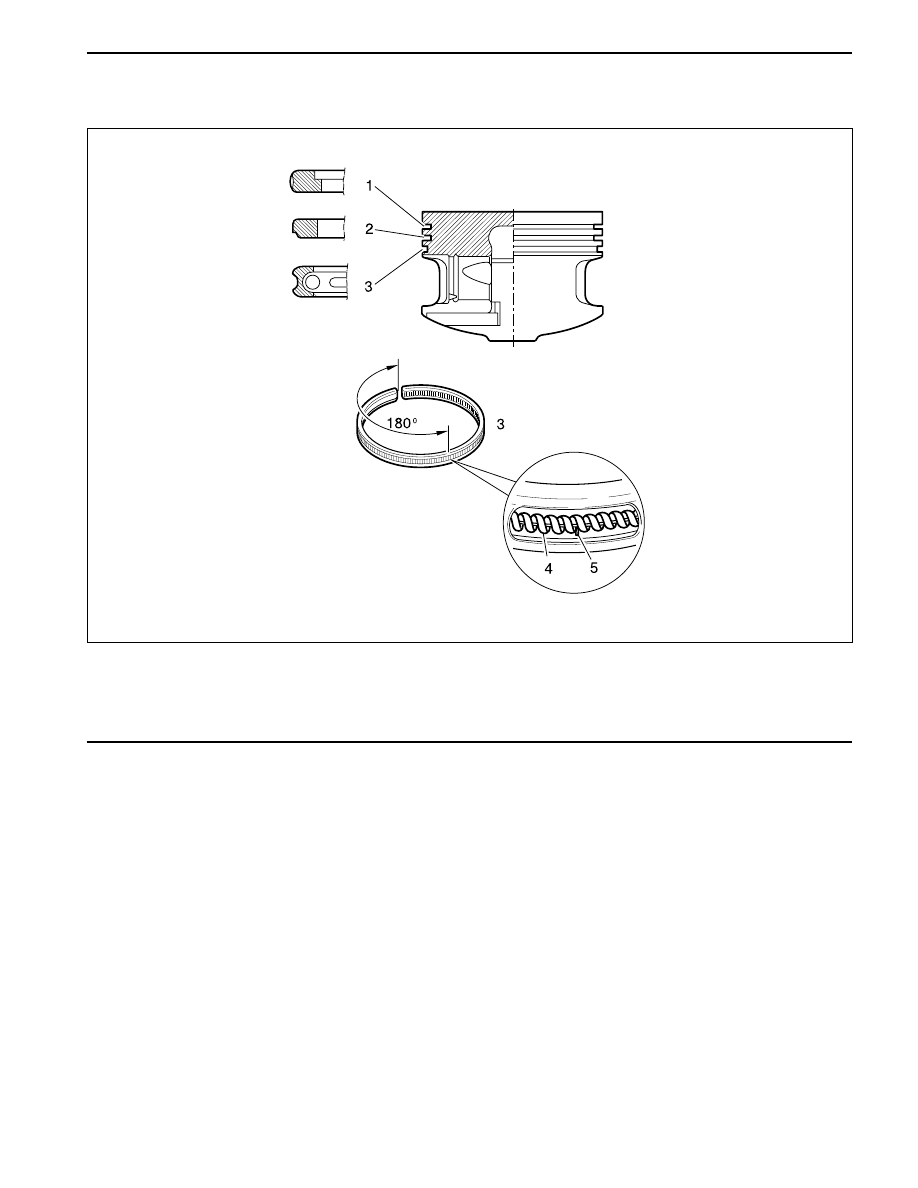

PISTON RING

Preceding Work : Removal of piston

1 Piston Compression Ring

2 Piston Compression Ring

3 Piston Oil Ring

YAD1B2T0

4 Coil Spring and Control Ring

5 Hook Spring