SsangYong Rexton. Service manual - part 312

M162 ENGINE MECHANICAL 1B1-51

SSANGYONG Y200

Inspection

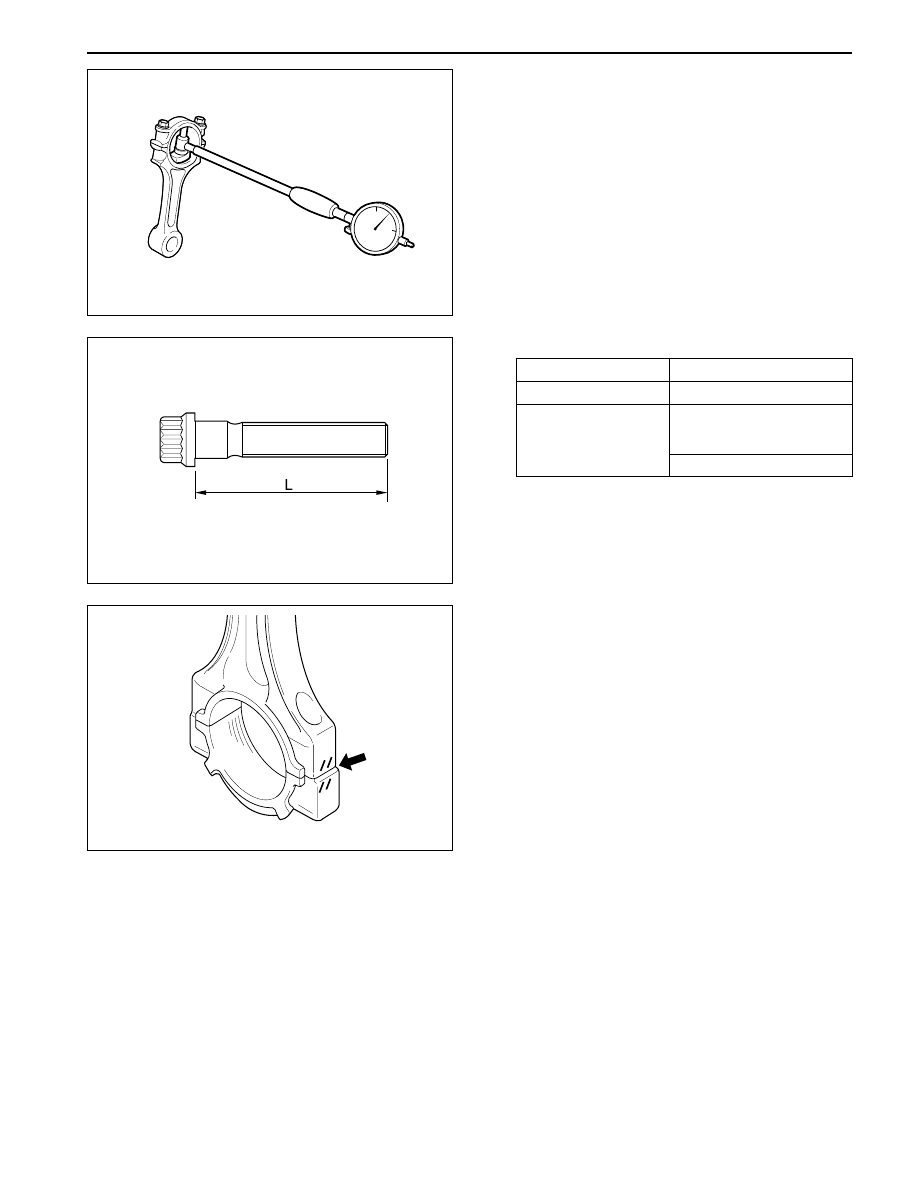

1. Measure the basic bore of the connecting rod

bearing.

Notice: If the basic bore exceeds the value of

51.614 mm, replace the bearing or check the

connecting rod.

2. Check connecting rod bolts.

3. Check the assembly mark(indication//or number:

arrow) of the connecting rods and the bearing cap

when installing.

Notice:

•

Make sure it doesn’t exceed over 4g with other

connecting rods when replacing the connecting

rods.

•

Check if the connecting rod and the bearing

cap are accurately seated on the groove when

replacing the bearing.

Notice: If the length exceeds max. length, replace

it.

YAD1B980

YAD1B990

YAD1B0A0

Length When New (L)

Max. Length (L)

Tightening Torque

51.7 - 52 mm

52.9 mm

1st step: 40 + 5 N•m

(30 + 3.7 lb-ft)

2nd step: 90°+10°