Nissan Versa Sedan. Instruction - part 392

CYLINDER BLOCK

EM-103

< UNIT DISASSEMBLY AND ASSEMBLY >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Inspection

INFOID:0000000009266678

CRANKSHAFT END PLAY

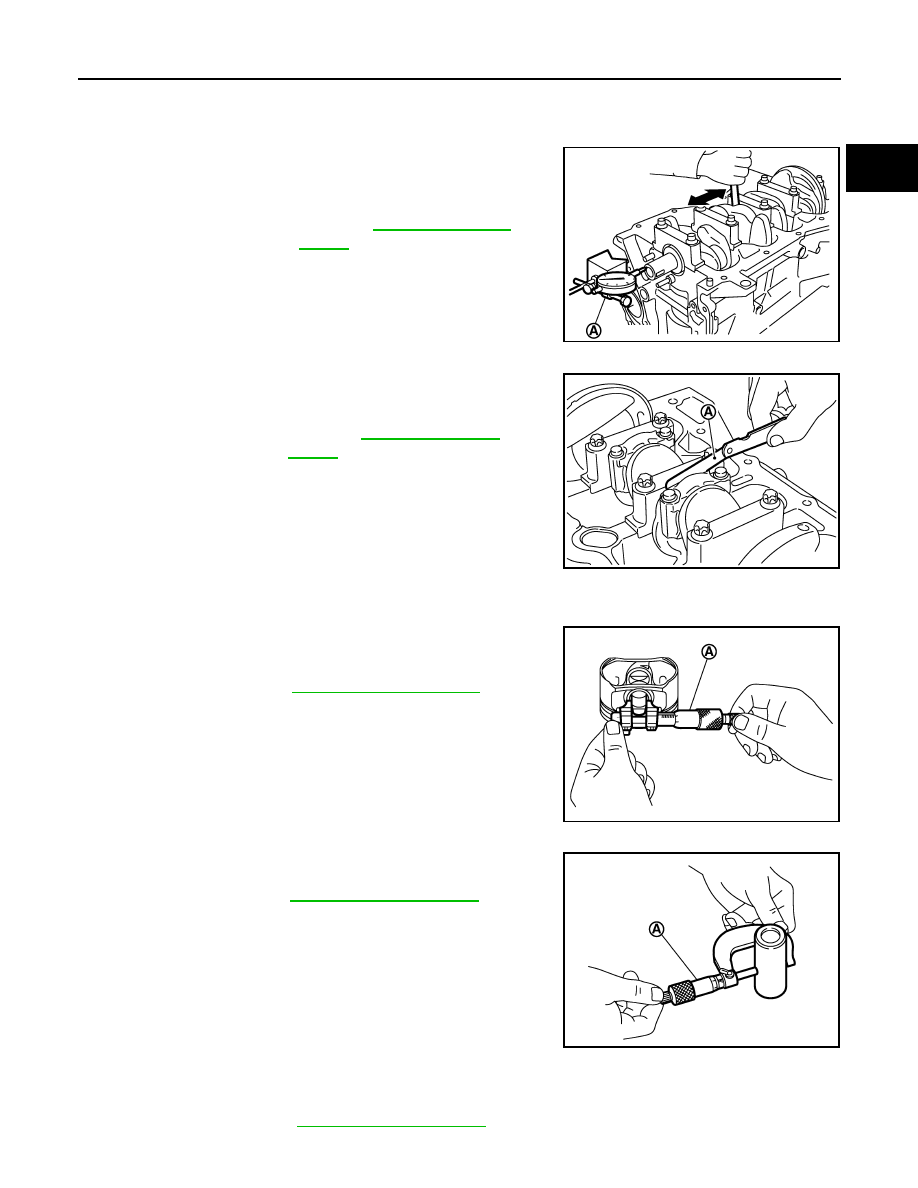

• Measure the clearance between thrust bearings and crankshaft

arm when crankshaft is moved fully forward or backward with a

suitable tool (A).

• If the measured value exceeds the limit, replace thrust bearings,

and measure again. If it still exceeds the limit, replace crankshaft

also.

CONNECTING ROD SIDE CLEARANCE

• Measure the side clearance between connecting rod and crank-

shaft arm with a suitable tool (A).

• If the measured value exceeds the limit, replace connecting rod,

and measure again. If it still exceeds the limit, replace crankshaft

also.

PISTON TO PISTON PIN OIL CLEARANCE

Piston Pin Hole Diameter

Measure the inner diameter of piston pin hole with an suitable tool

(A).

Piston Pin Outer Diameter

Measure the outer diameter of piston pin with a suitable tool (A).

Piston to Piston Pin Oil Clearance

(Piston to piston pin oil clearance) = (Piston pin hole diameter) – (Piston pin outer diameter)

Standard and Limit

: Refer to

.

PBIC3762E

Standard and Limit : Refer to

.

PBIC3763E

Standard

: Refer to

.

PBIC3265J

Standard :

Refer

PBIC3266J

Standard :