Nissan Versa Sedan. Instruction - part 390

CYLINDER BLOCK

EM-95

< UNIT DISASSEMBLY AND ASSEMBLY >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Disassembly and Assembly

INFOID:0000000009266677

DISASSEMBLY

NOTE:

The following procedures explain how to disassemble the engine with the engine stand fastened to the bell

housing. Some steps may be different if using a different type of engine stand.

1. Remove cylinder head. Refer to

2. Remove knock sensor.

CAUTION:

Carefully handle knock sensor avoiding shocks.

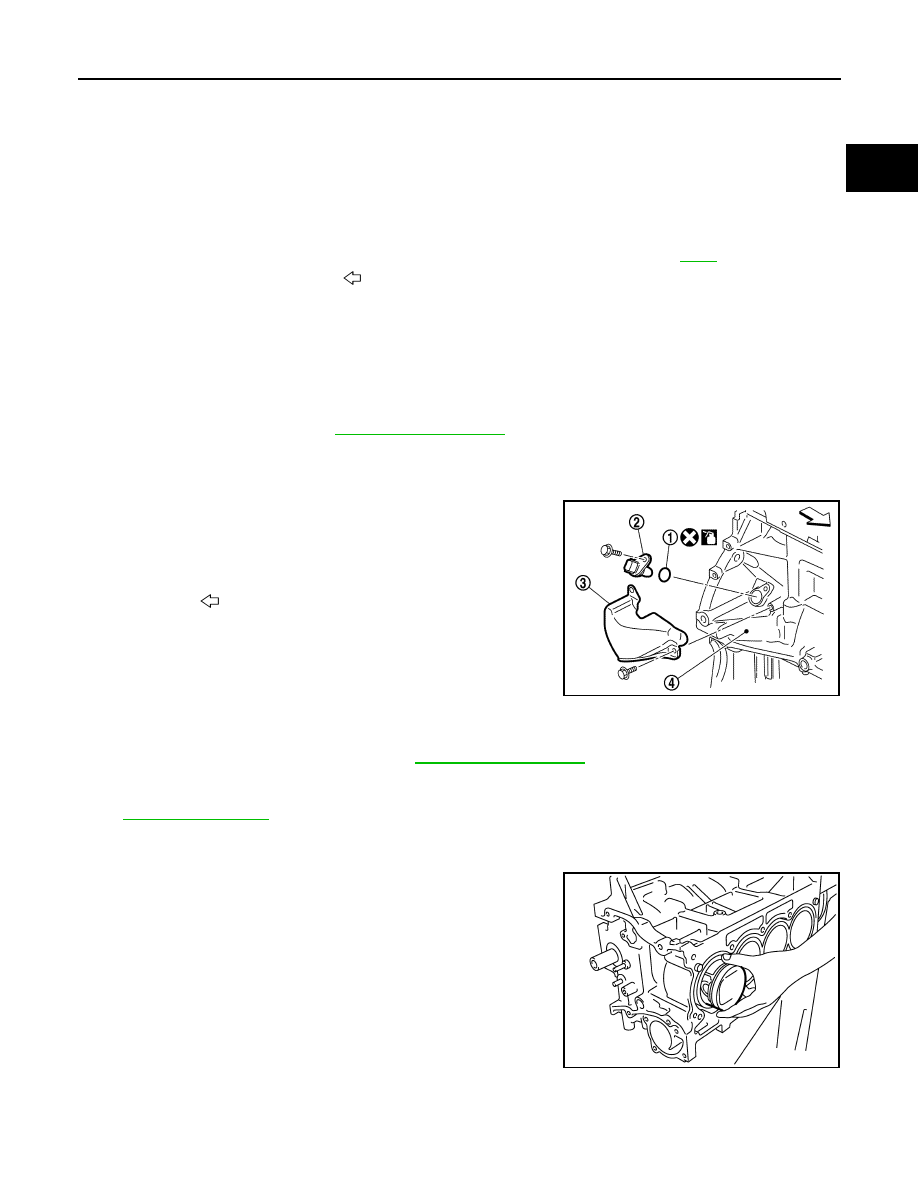

3. Remove the crankshaft position sensor cover (3), and then

crankshaft position sensor (POS) (2).

CAUTION:

• Avoid impacts such as a dropping.

• Do not disassemble.

• Keep sensor away from metal particles.

• Do not place the sensor in a location where it is exposed

to magnetism.

• Do not reuse O-ring.

4. Remove oil pan (upper and lower). Refer to

5. Remove piston and connecting rod assembly:

• Before removing piston and connecting rod assembly, check the connecting rod side clearance. Refer to

.

a. Position crankshaft pin corresponding to connecting rod to be removed onto the bottom dead center.

b. Remove connecting rod cap.

c. Using a hammer handle or similar tool, push piston and connect-

ing rod assembly out through the cylinder head side.

CAUTION:

• Be careful not to damage mating surface with connecting

rod cap.

• Be careful not to damage the cylinder wall or crankshaft

pin.

6. Remove connecting rod bearings.

CAUTION:

Identify original positions for installation, and store the bearings without mixing them up.

10. Oil temperature sensor

11. Oil pressure sensor

12. Oil jet

13. Top ring

14. Second ring

15. Oil ring

16. Piston

17. Piston pin

18. Connecting rod

19. Connecting rod bearing (upper)

20. Main bearing (upper)

21. Thrust bearing

22. Crankshaft key

23. Connecting rod bolt

24. Connecting rod cap

25. Connecting rod bearing (lower)

26. Main bearing (lower)

27. Crankshaft

28. Pilot converter (A/T and CVT models)

29. Signal plate

30. Rear oil seal

31. Drive plate (A/T and CVT models)

32. Reinforce plate (A/T and CVT models) 33. Flywheel (M/T models)

34. Main bearing cap

35. Main bearing cap bolt

A.

Refer to

B.

Chamfered

: Crankshaft side

(1) O-ring

(4) Cylinder block

: Engine front

JPBIA4202ZZ

KBIA3365J