Nissan Versa Sedan. Instruction - part 389

OIL PAN (UPPER) AND OIL STRAINER

EM-91

< UNIT DISASSEMBLY AND ASSEMBLY >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

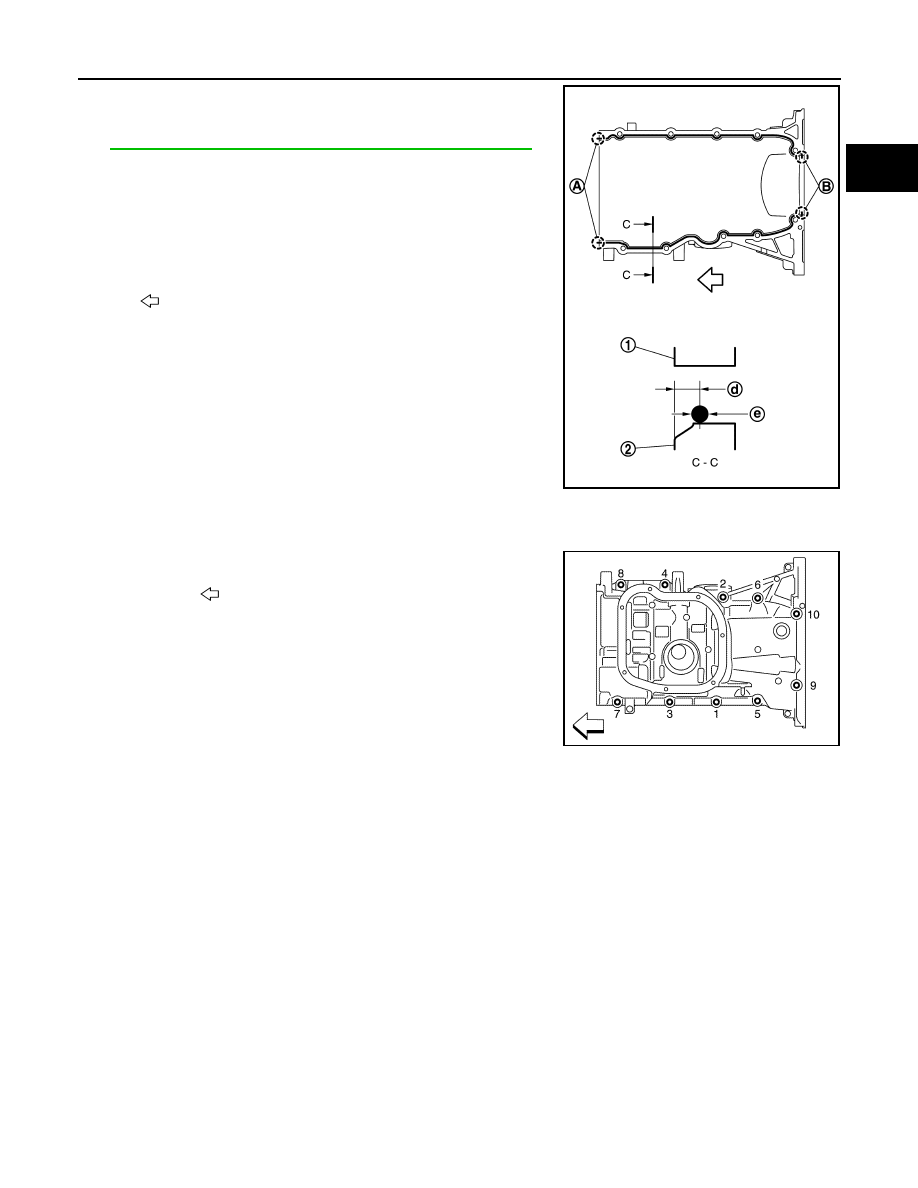

c. Apply a continuous bead of liquid gasket with the Tool or suitable

tool to areas as shown.

Use Genuine Silicone RTV Sealant or equivalent. Refer to

GI-21, "Recommended Chemical Products and Sealants"

.

CAUTION:

Attaching should be done within 5 minutes after coating.

d. Tighten bolts in the numerical order as shown.

CAUTION:

Install avoiding misalignment of both oil pan gasket and O-

ring.

• The bolts are different according to the installation position.

Refer to the numbers as shown.

2. Install rear oil seal:

CAUTION:

• The installation of rear oil seal should be completed within 5 minutes after installing oil pan

(upper).

• Do not touch oil seal lip.

a. Wipe off any liquid gasket protruding to the rear oil seal mounting part of oil pan (upper) and cylinder block

using a suitable tool.

b. Apply the liquid gasket lightly to entire outside area of new rear oil seal.

Use Genuine Liquid Gasket or equivalent.

(1) : Cylinder block

(2) : Oil pan (upper)

(A) : 2 mm (0.07 in) protruded to outside

(B) : 2 mm (0.07 in) protruded to rear oil seal mounting side

(d) : 5.5 - 7.5 mm (0.217 - 0.295 in)

(e) : 4.0 - 5.0 mm (0.157 - 0.197 in) diameter

: Engine front side

JSBIA1301ZZ

: Engine front

M8

×180 mm (7.09 in)

: No. 9, 10

M8

×25 mm (0.98 in)

: No. 4, 7, 8

M8

×90 mm (3.54 in)

: No. 1, 2, 3, 5, 6

JPBIA4199ZZ