Nissan Versa Sedan. Instruction - part 391

CYLINDER BLOCK

EM-99

< UNIT DISASSEMBLY AND ASSEMBLY >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

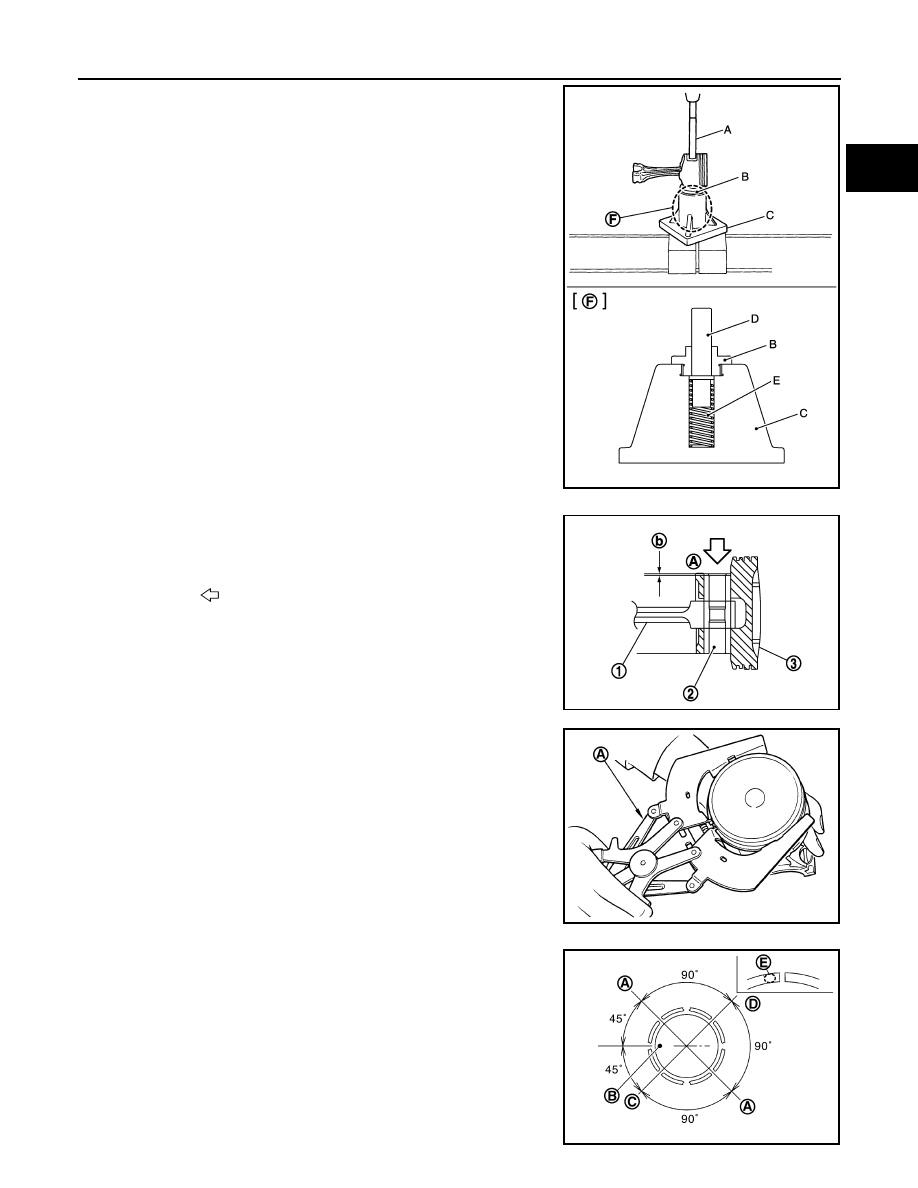

b. Press-fit the piston pin using the Tools (A, B, C, D, E).

CAUTION:

Press-fit the piston so as not to damage it.

NOTE:

The joint between the connecting rod and the piston pin is a

press fit.

• Press-fit the piston pin (2) from piston surface (A) to the depth

of 2.35 mm (0.092 in) (b).

• After finishing work, check that the piston (3) moves freely.

9. Using suitable tool (A), install piston rings.

CAUTION:

• Be careful not to damage piston.

• Be careful not to damage piston rings by expanding them

excessively.

• Position each ring with the gap as shown referring to the pis-

ton front mark (B).

• Install second ring with the stamped mark (E) facing upward.

Tool number (A) : KV10109730

(B)

: KV10110310

(C)

: ST13030020

(D)

: KV10114120

(E)

: ST13030030

(F)

: Detail

PBIC5271J

(1) : Connecting rod

: Press-fit direction

JPBIA2058ZZ

PBIC3233J

(A)

: Oil ring upper or lower rail gap (either of them)

(C)

: Second ring and oil ring spacer gap

(D)

: Top ring gap

PBIC3752E