Nissan Versa Sedan. Instruction - part 393

CYLINDER BLOCK

EM-107

< UNIT DISASSEMBLY AND ASSEMBLY >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Piston Skirt Diameter

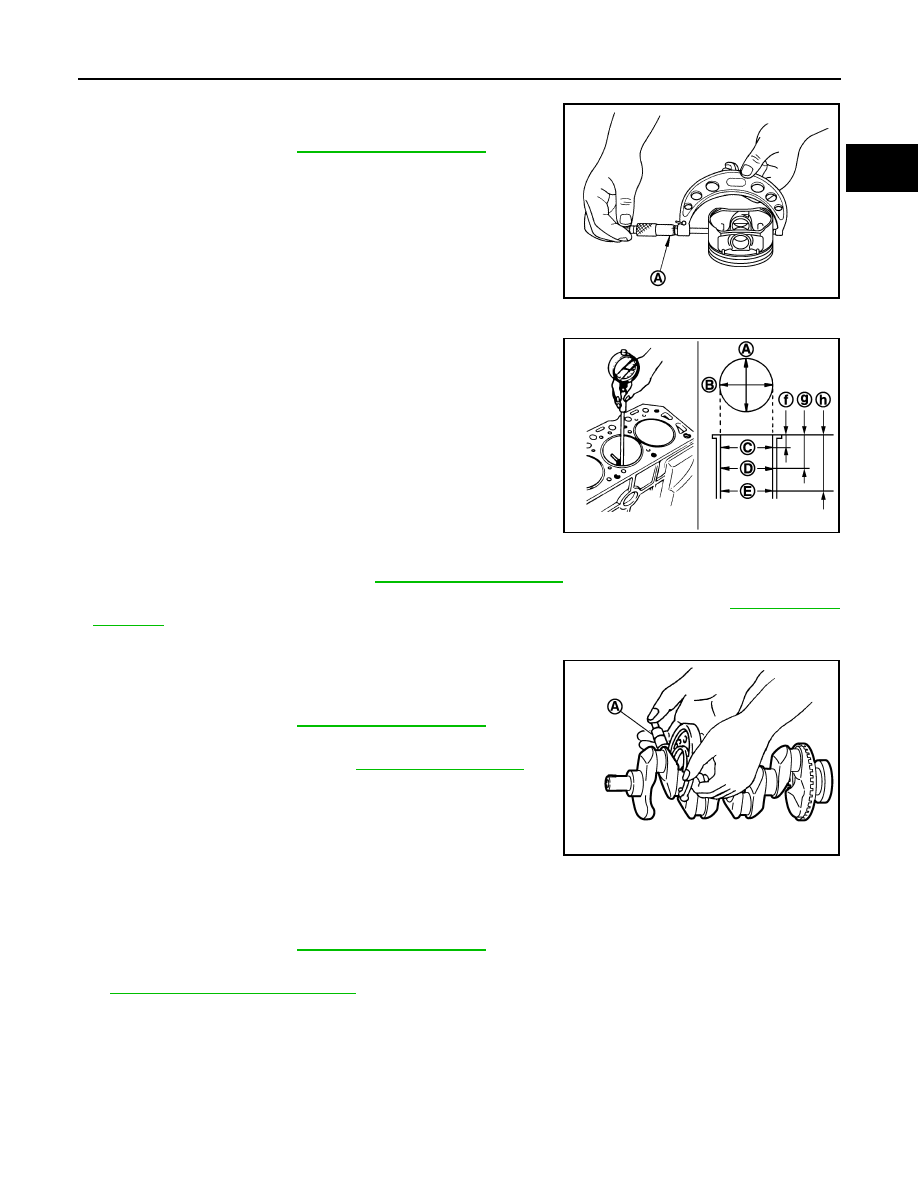

Measure the outer diameter of piston skirt with a suitable tool (A).

Piston to Cylinder Bore Clearance

Calculate by piston skirt diameter and cylinder bore inner diameter

[direction (B), position (D)].

(Clearance) = (Cylinder bore inner diameter) – (Piston skirt diame-

ter)

• If it exceeds the limit, replace piston and piston pin assembly and/or cylinder block. Refer to

CRANKSHAFT MAIN JOURNAL DIAMETER

• Measure the outer diameter of crankshaft main journals with a suit-

able tool (A).

• If out of the standard, measure the main bearing oil clearance.

Then use undersize bearing. Refer to

CRANKSHAFT PIN JOURNAL DIAMETER

• Measure the outer diameter of crankshaft pin journal with a suitable tool.

• If out of the standard, measure the connecting rod bearing oil clearance. Then use undersize bearing. Refer

EM-126, "Connecting Rod Bearing"

.

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

Standard :

PBIC3272J

(A)

: Direction A

(C)

: Position C

(E)

: Position E

(f)

: 10 mm (0.39 in)

(g)

: 60 mm (2.36 in)

(h)

: 124 mm (4.88 in)

Standard and Limit

: Refer to

.

JPBIA2059ZZ

Standard :

PBIC3457J

Standard :