Nissan Versa Sedan. Instruction - part 383

CAMSHAFT

EM-67

< REMOVAL AND INSTALLATION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

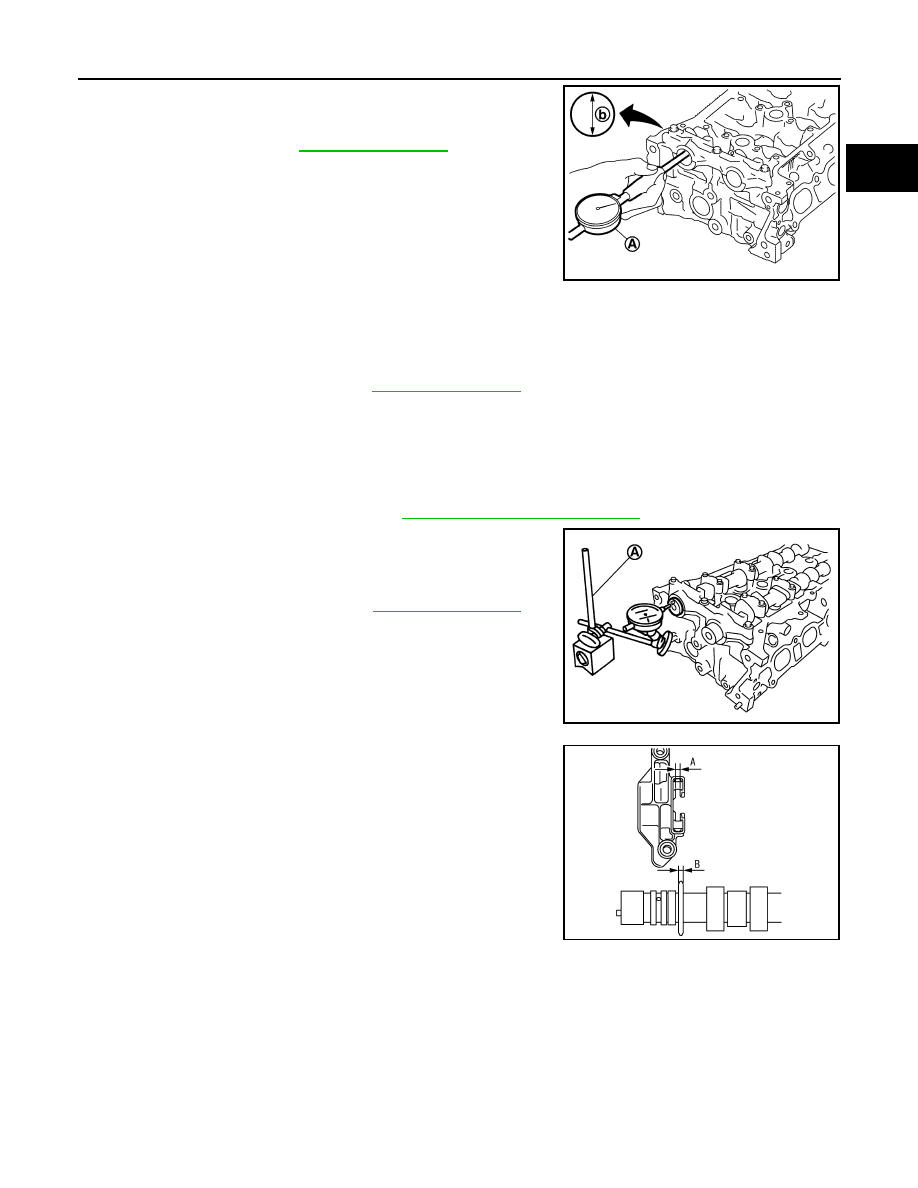

• Measure inner diameter (b) of camshaft bracket with a bore gauge

(A).

CAMSHAFT JOURNAL OIL CLEARANCE

• (Oil clearance) = (Camshaft bracket inner diameter) – (Camshaft journal diameter)

• If it exceeds the limit, replace either or both camshaft and cylinder head.

NOTE:

Camshaft brackets cannot be replaced as single parts, because they are machined together with cylinder

head. Replace whole cylinder head assembly.

Camshaft End Play

1. Install camshaft in cylinder head. Refer to

EM-56, "Removal and Installation"

2. Install a dial indicator (A) in thrust direction on front end of cam-

shaft. Measure the camshaft end play on the dial indicator when

camshaft is moved forward/backward (in direction to axis).

• Measure the following parts if out of the standard.

- Dimension “A” for cylinder head No. 1 journal bearing

- Dimension “B” for camshaft thrust

• Refer to the standards above, and then replace camshaft and/

or cylinder head.

Camshaft Sprocket Runout

1. Put V-block on precise flat table, and support No. 2 and 5 journals of camshaft.

CAUTION:

Do not support No. 1 journal (on the side of camshaft sprocket) because it has a different diameter

from the other four locations.

Standard

: Refer to

.

JPBIA4192ZZ

Standard and Limit

: Refer to

.

Standard and Limit

: Refer to

.

PBIC3694E

Standard

: 4.000 - 4.030 mm (0.1574 - 0.1586 in)

Standard

: 3.877 - 3.925 mm (0.1526 - 0.1545 in)

KBIA3345J