Nissan Versa Sedan. Instruction - part 382

CAMSHAFT

EM-63

< REMOVAL AND INSTALLATION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

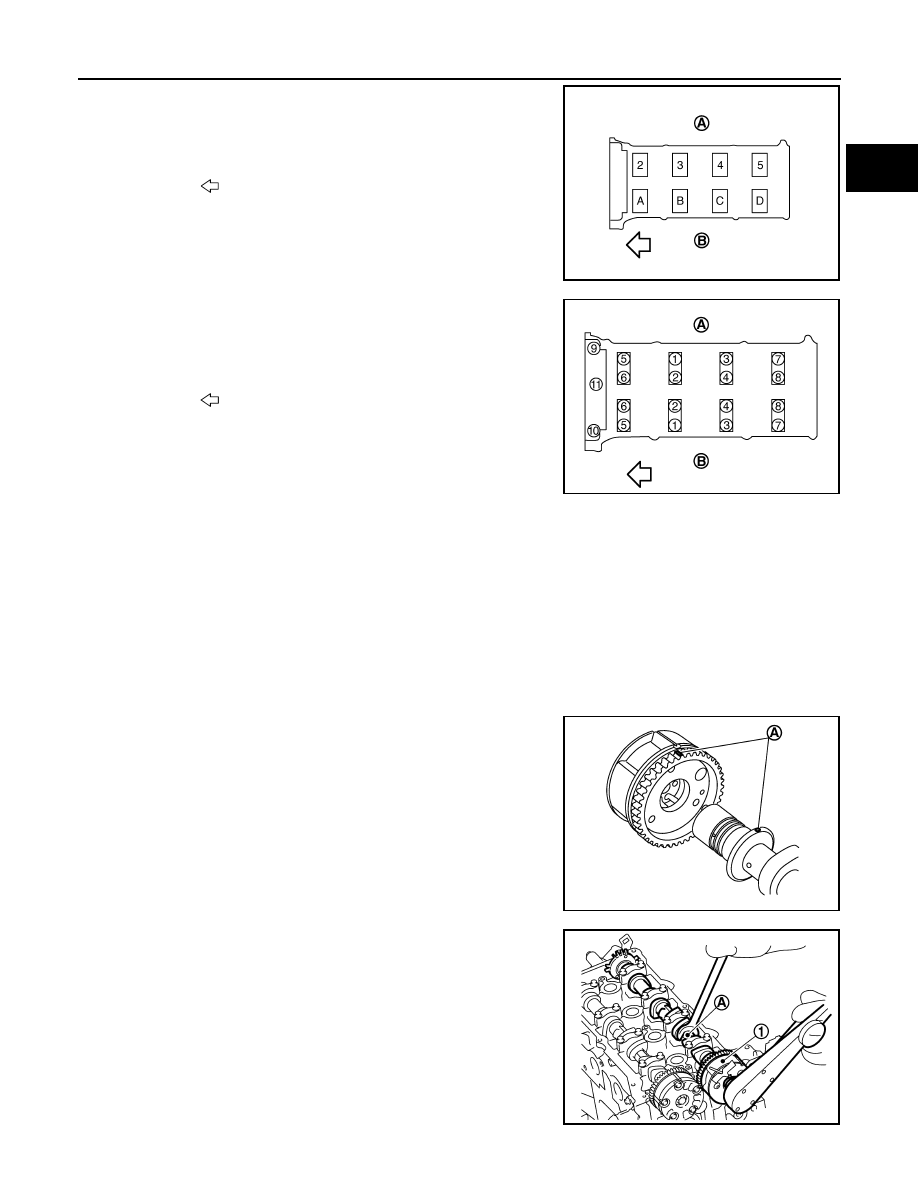

7. Install camshaft brackets (No. 2 to 5) aligning the identification

marks on upper surface as shown.

• Install so that identification mark can be correctly read when

viewed from the INT side.

8. Tighten bolts of camshaft brackets in the following steps, in

numerical order as shown.

a. Tighten No. 9 to 11 in numerical order.

b. Tighten No. 1 to 8 in numerical order.

c. Tighten all bolts in numerical order.

d. Tighten all bolts in numerical order.

9. Install the camshaft sprocket (INT and EXH) to the camshaft (INT and EXH):

a. Refer to the matching mark (A) added in step 4. Securely align

the knock pin and the pin hole, and then install them.

NOTE:

The intake side is shown as an example.

10. Tighten the camshaft sprocket bolt (INT and EXH).

CAUTION:

Hold the camshaft hexagonal part (A), using a suitable tool

to secure the camshaft.

(A) : EXH side

(B) : INT side

: Engine front

PBIC3703E

(A) : EXH side

(B) : INT side

: Engine front

Camshaft bracket bolts

: 1.96 N·m (2.0 kg-m, 14 in-lb)

Camshaft bracket bolts

: 1.96 N·m (2.0 kg-m, 14 in-lb)

Camshaft bracket bolts

: 5.88 N·m (0.60 kg-m, 52 in-lb)

Camshaft bracket bolts

: 10.4 N·m (1.1 kg-m, 8 ft-lb)

PBIC3686E

PBIC3700E

(1) : Camshaft sprocket (EXH)

JPBIA4158ZZ