Nissan Versa Sedan. Instruction - part 381

CAMSHAFT

EM-59

< REMOVAL AND INSTALLATION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

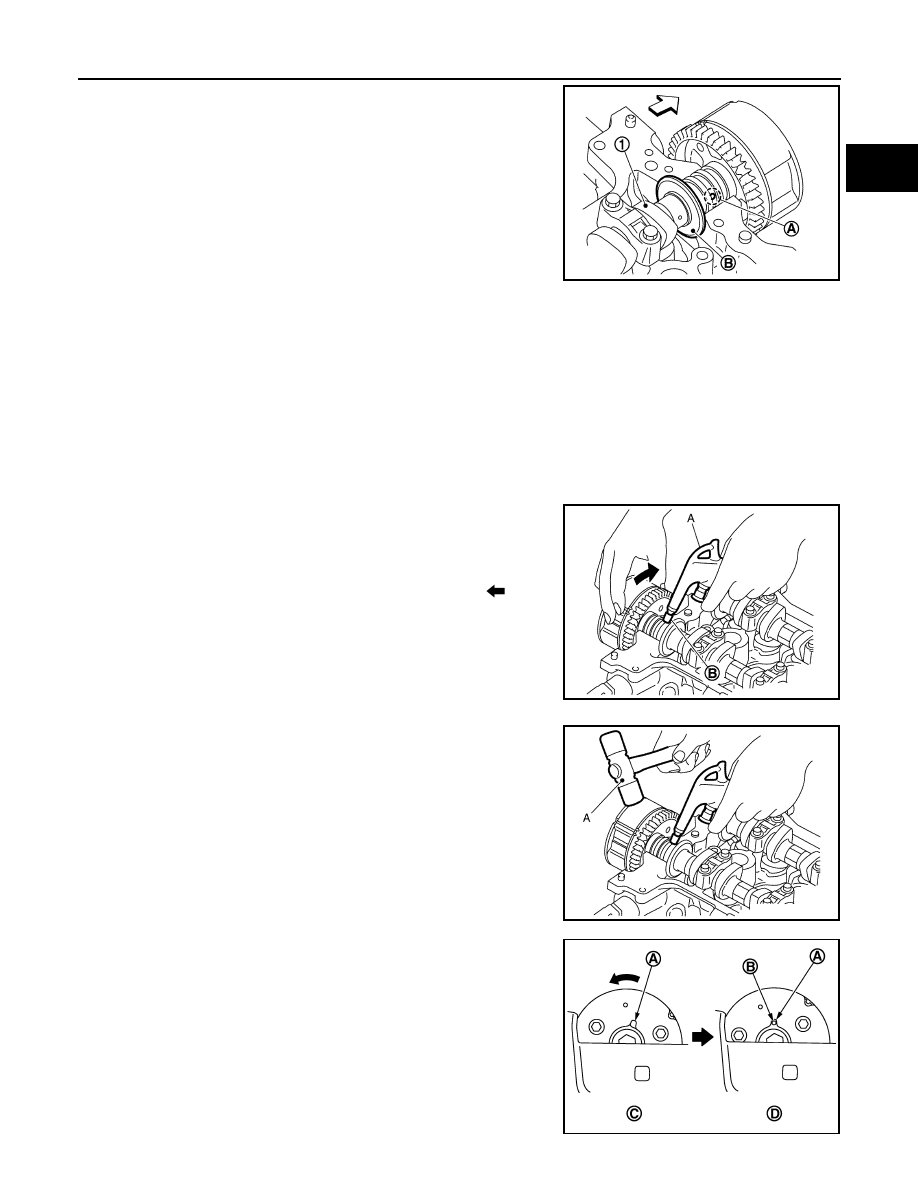

b. Apply the following air pressure to the No. 1 journal oil hole (A)

of camshaft (INT) (1) shown using an air gun.

• Apply the air pressure into the oil hole on the second groove

from the front of camshaft thrust (B).

• Proceed all the way through step “e” with the air pressure on.

• Attach the rubber nozzle narrowed to the top of the air gun to

prevent air leakage from the oil hole (A). Securely apply the air

pressure to the oil hole.

WARNING:

Eye protection should be worn as needed.

CAUTION:

• There are other oil holes in the side grooves. Do not use the incorrect oil holes.

• Be sure not to damage the oil path with the tip of the air gun.

• Wipe all the oil off the air gun to prevent oil from being blown all over along with the air, and the

area around the air gun should be wiped with a rag when applying air pressure. Eye protection

should be worn as needed.

NOTE:

The air pressure is used to move the lock pin into the disengage position.

c. Hold the camshaft sprocket (INT) with hands, and then apply the power counterclockwise/clockwise alter-

nately.

• Finally rotate the sprocket of the camshaft sprocket (INT)

counterclockwise [the direction shown by the arrow (

)].

• Perform the work while continuously applying the air pressure

to the oil hole.

• If the lock pin is not released, tap the camshaft sprocket (INT)

lightly with a plastic hammer (A).

• If the camshaft sprocket (INT) is not rotated counterclockwise

even if the above procedures are performed, check the air

pressure and the oil hole position.

d. While doing the above, once you hear a click (the sound of the

internal lock pin disengaging) from inside the camshaft sprocket

(INT), start turning the camshaft sprocket (INT) in the counter-

clockwise direction in the most advanced angle position.

• Keep the air pressure on.

• If there is no click, as soon as the vane side (camshaft side)

starts moving independently of the sprocket, the lock pin has

become disengaged.

Air pressure

: 300 kPa (3.1 kg/cm

2

, 44 psi) or more

JPBIA4150ZZ

(A) : Air gun

(B) : Rubber nozzle

JPBIA4151ZZ

JPBIA4152ZZ

(C) : Lock pin engaged

(D) : Most advanced angle

PBIC3684E