Nissan Versa Sedan. Instruction - part 379

TIMING CHAIN

EM-51

< REMOVAL AND INSTALLATION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

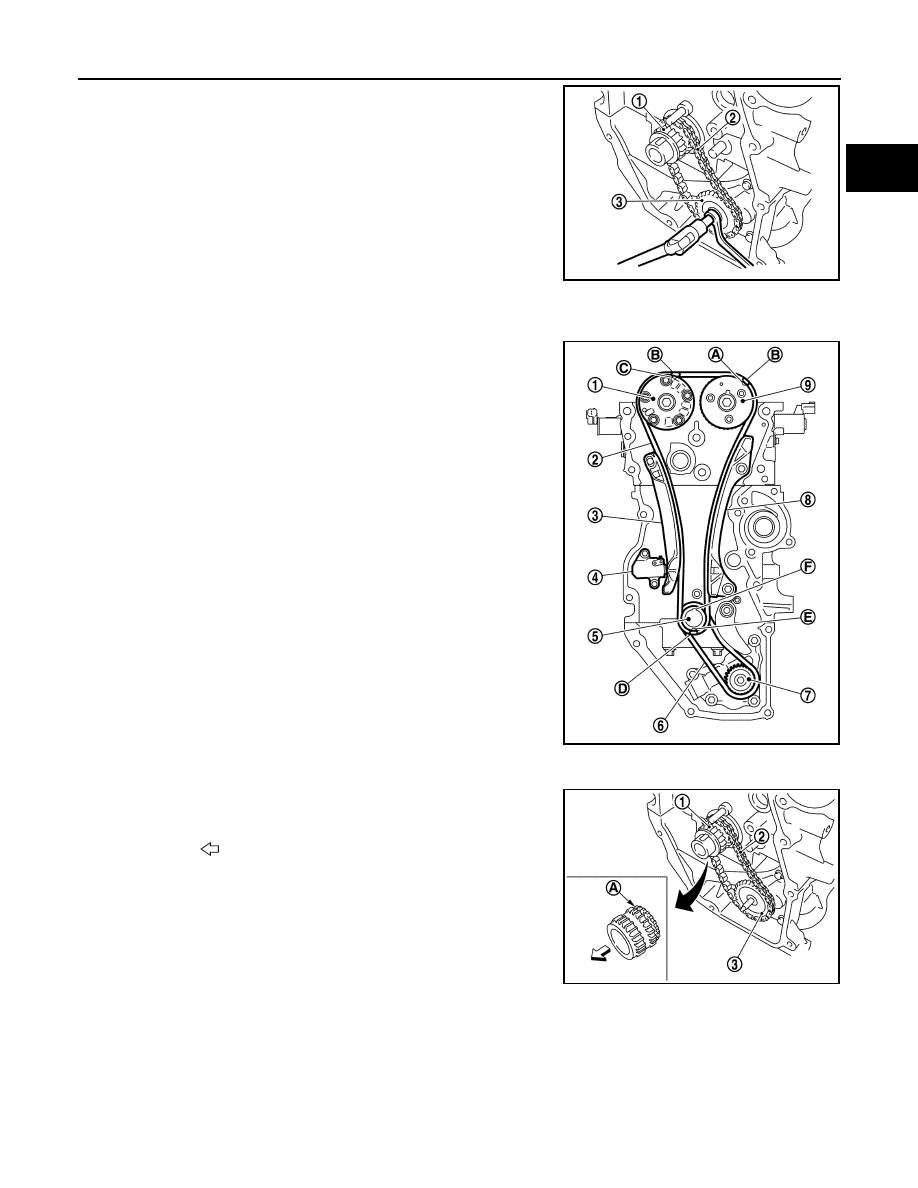

b. Hold the top of the oil pump shaft using the socket (size: E8),

and then loosen the oil pump sprocket nut and remove it.

c. Remove the crankshaft sprocket (1), the oil pump drive chain

(2), and the oil pump sprocket (3) at the same time.

INSTALLATION

NOTE:

For installation follow the relationship between the matching mark on

each timing chain and that of the corresponding sprocket, with the

components installed.

1. Install the crankshaft sprocket and the oil pump drive related parts:

a. Install the crankshaft sprocket (1), the oil pump drive chain (2),

and the oil pump sprocket (3) at the same time.

• Install the crankshaft sprocket so that its invalid gear area (A)

is toward the back of the engine.

• Install the oil pump sprocket so that its protrusion faces the

front of engine.

NOTE:

There is no matching mark in the oil pump drive related parts.

JPBIA4230ZZ

(1) : Camshaft sprocket (EXH)

(2) : Timing chain

(3) : Timing chain slack guide

(4) : Chain tensioner

(5) : Crankshaft sprocket

(6) : Oil pump drive chain

(7) : Oil pump sprocket

(8) : Timing chain tension guide

(9) : Camshaft sprocket (INT)

(A) : Matching mark (Peripheral groove)

(B) : Pink link

(C) : Matching mark (Peripheral groove)

(D) : Orange link

(E) : Matching mark (stamp)

(F) : Crankshaft key (point straight up)

JPBIA4223ZZ

: Engine front

JPBIA5248ZZ