Nissan Qashqai (2007-2010). Manual - part 683

BRAKE BOOSTER

BR-31

< ON-VEHICLE REPAIR >

[LHD]

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

Note the following, and installation is the reverse order of removal.

CAUTION:

• Be careful not to damage brake booster stud bolt threads. If brake booster is tilted during installa-

tion, the dash panel may damage the threads.

• Never deform or bend the brake tubes when installing the brake booster.

• Always use a new gasket between the brake booster and the spacer.

• Replace the clevis pin if it is damaged. Refer to

BR-18, "Inspection and Adjustment"

• After installation, perform the air bleeding. Refer to

BR-12, "Bleeding Brake System"

.

CAUTION:

Never reuse drained brake fluid.

Inspection and Adjustment

INFOID:0000000000925808

INSPECTION AFTER REMOVAL

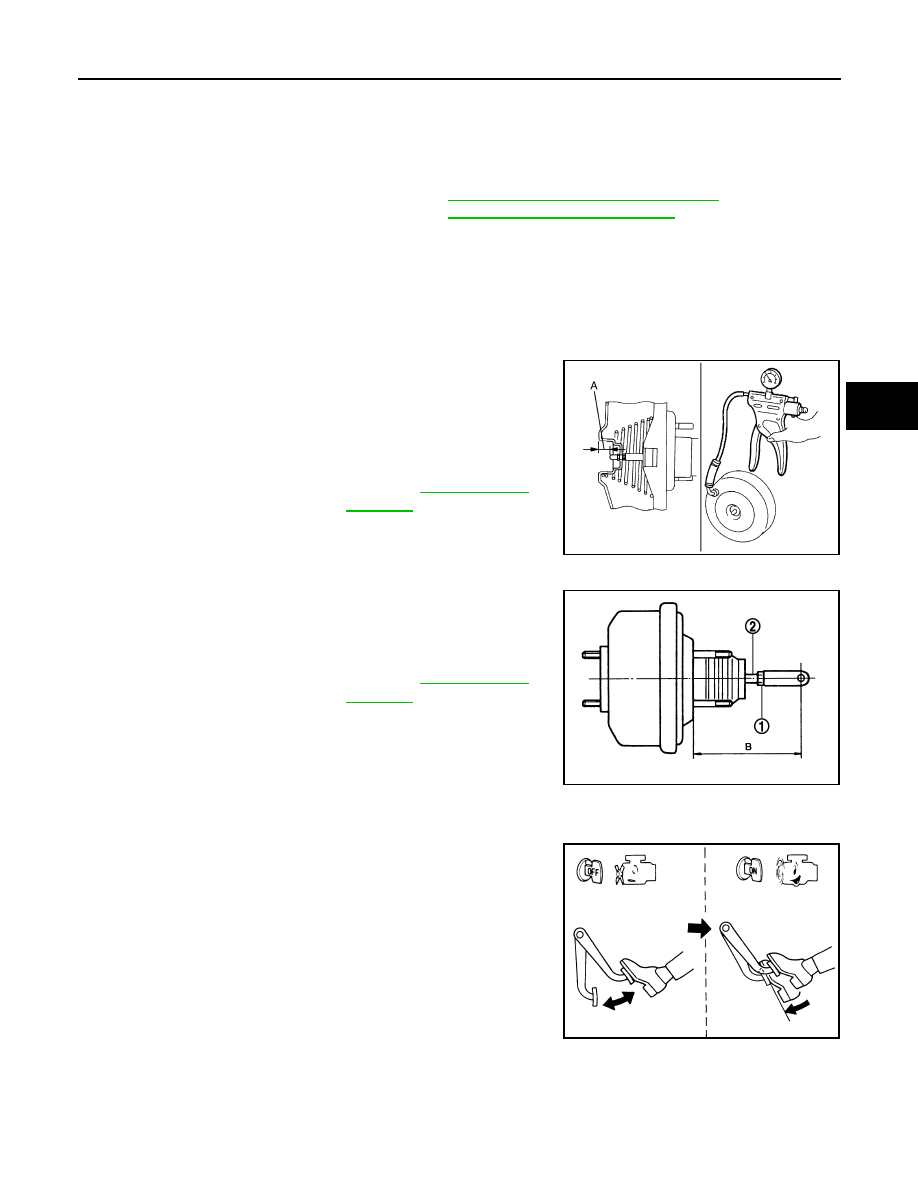

Output Rod Length Inspection

1.

With a handy vacuum pomp, apply vacuum pressure of

−

66.7

kPa (

−

500 mmHg,

−

19.70 inHg,

−

0.667 bar) to the brake

booster.

2.

Check the output rod length (A).

Input Rod Length Inspection

1.

Loosen the lock nut (1) and adjust the input rod (2) to the speci-

fied length (B).

2.

Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation

Depress the brake pedal several times at 5-second intervals with the

engine stopped. Start the engine with the brake pedal fully

depressed. Check that the clearance between brake pedal and dash

lower pane decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due to

the brake system operation.

Air Tight

Standard

Output rod length (A)

: Refer to

.

JPFIA0021ZZ

Standard

Input rod length (B)

: Refer to

.

JPFIA0020ZZ

BRA0037D