Haima S5. Chassis System. Instruction - part 5

Brake system 2F-10

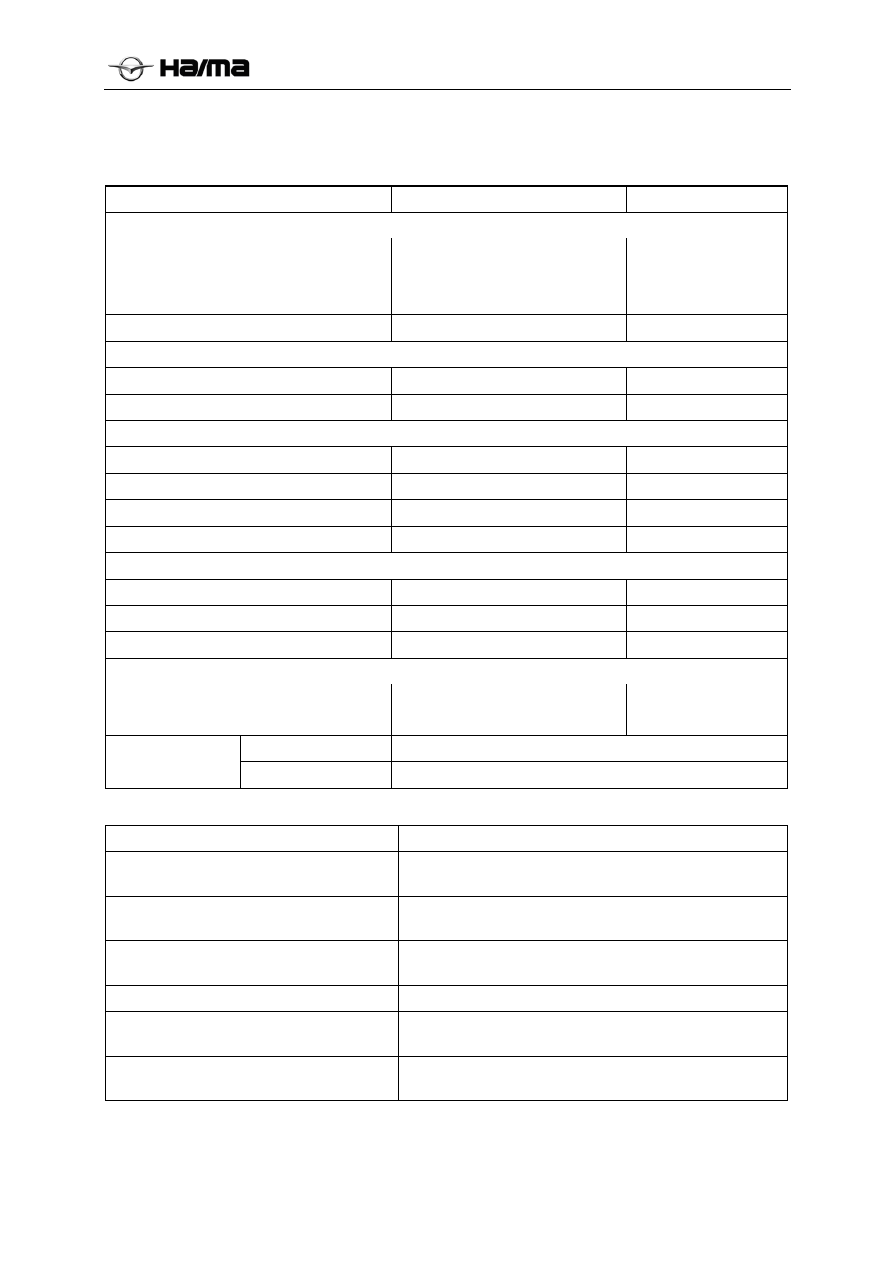

Specifications

General parameters

Item mm

Front brake

Diameter of brake disc

Thickness of brake disc

Valid thickness of disc

φ296

26

24

Diameter of caliper cylinder

Φ60.3

Rear-drum brake

Specification

Φ172×20

Inner diameter of brake drum

Φ172

Rear-disc brake

Diameter of brake disc

φ292

Thickness of brake disc

9

Valid thickness of disc

7

caliper cylinder diameter

φ35

Vacuum booster with brake master cylinder assembly

Assist rate

9

diameter of master cylinder

23.8

Stroke of master cylinder

18+18

Brake pedal

free stroke

Valid stroke

6-10

120

Type DOT-4

brake fluid

Capacity 700ml±50ml

Tightening torque specifications of fasteners

Application

N·m

Install the brake oil pipe at the joint of

brake oil pipe.

14 to 18

Mounting bolt of front brake hose and

caliper

22 to 29

Connecting bolt of brake pedal and pedal

support

19 to 25

brake hose support tightening bolt

8 to 14

Connecting bolt of wheel speed sensor

support

8 to 14

ABS/ESP/proportional valve support

mounting bolt

20 to 24