Haima S5. Chassis System. Instruction - part 4

Steering system 2E-15

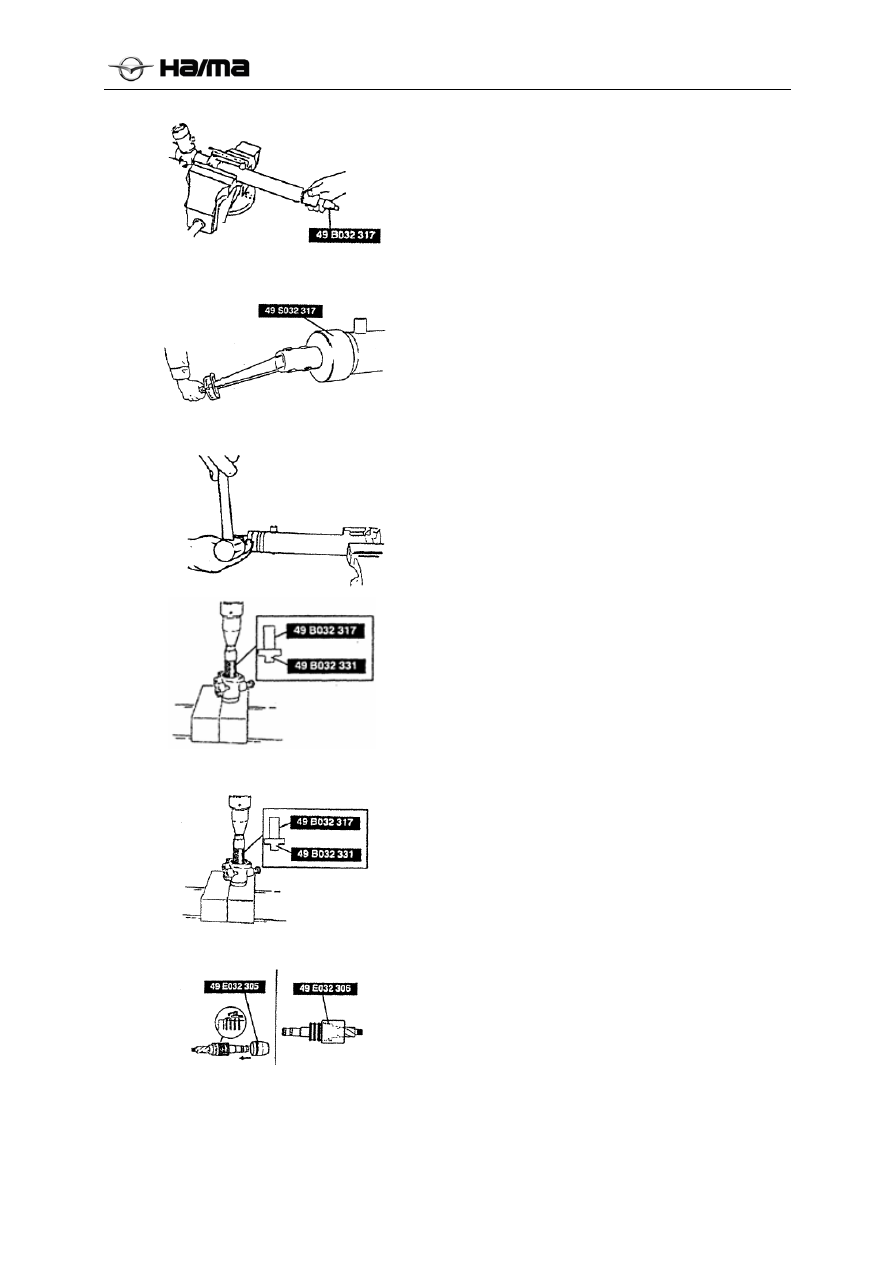

Keypoints for installing the hoop

1. Apply a little of lubricating oil to “O” ring and

U seal gasket.

2. Install “O” ring and U seal gasket on the socket

sleeve.

3. Install them on the steering gear with a special

tool.

4. Install the hoop with a special tool.

5. Fix the hoop on cylinder body with a chisel.

Keypoints for installing the oil seal

1. Apply the appropriate amount of grease to new

oil seal.

2. Press in the new oil seal with a special tool.

Keypoints for installing upper bearing

1. Apply the appropriate amount of grease to new

upper bearing.

2. Press in the bearing with a special tool.

1. Attach a new seal ring to the valve body of

gear shaft with a special tool.

2. After the installation, place the seal ring in

position with a special tool.

3. Install the snap ring.