Haima S5. Chassis System. Instruction - part 3

Suspension system 2D-4

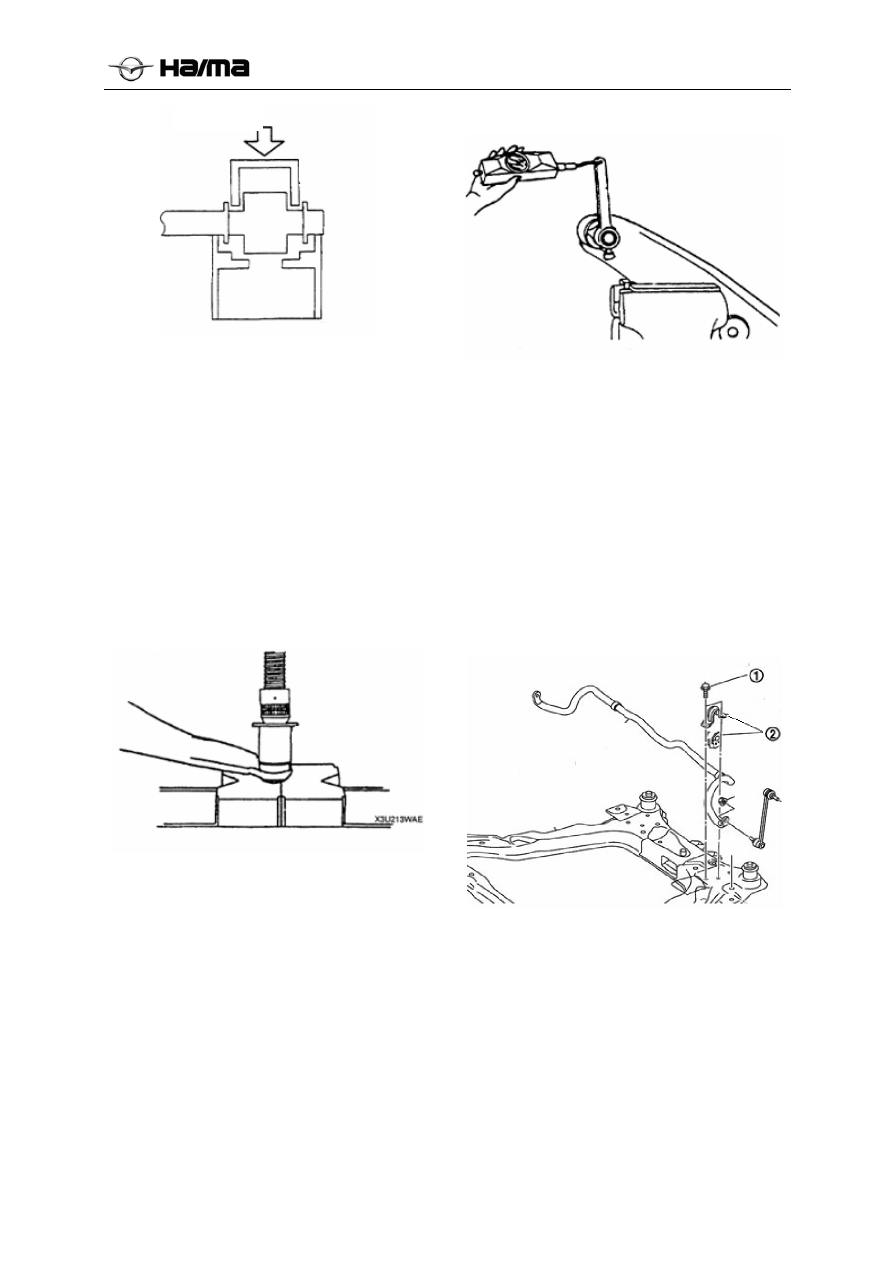

Keypoints for installing the lower swing front

bush

1. Place the alignment mark on the demolition

done, make sure the angle of the bushing press-

fitting the body correctly.

2. Press a new bush into swing arm body with SST

special service tool.

Keypoints for installing the dust cover

1. Wipe off the grease from the ball head bolt.

2. Fill the grease into the new dust cover.

3. Press the dust cover on the ball joint with SST

special service tool.

4. Wipe off the excessive grease.

Check of front lower swing arm

1. Remove lower swing arm from the vehicle.

2. Check it for damages, cracks and bends.

3. Check the rotation torque of ball joint.

(1) Turn the ball joint five times.

(2) Connect SST special service tool to ball head

bolt, and measure its rotation torque with a

tension meter. If unqualified, replace the

lower swing arm.

Pre-load of ball joint: 1.0 -4.9N.m {0.1-0.5kgf.cm,

0.74-3.6in.lbf}

Reading of tension meter: 10-49N {1-5kgf, 0.225-

1.1lbf}

Removal/installation of front transverse

stabilizer bar

1. Remove the front suspension crossbeam

assembly (refer to the removal/installation of

R-9 front suspension crossbeam assembly).

2. Remove the control front stabilizer bar

connecting rod assembly and coupling nut ①.

3. Remove the front stabilizer bar fixing plate

nut, front stabilizer bar fixing plate, stabilizer

bar rubber bushings, stabilizer bar rubber seat

②

.

4. Install it in the reverse sequence of removal.

Keypoints for installing front transverse

stabilizer bar fixing plate

1. Apply the rubber grease to inner surface of

stabilizer bar rubber sleeve.

2. When installing rubber sleeve, insert the

rubber sleeve notch toward the vehicle rear

stabilizer bar fixing plate of the hole toward

the rear of the car.

3. Before installing the stabilizer bar fixing plate.

Press in