Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 881

♦ Torque Wrench 1332 40-200Nm - VAG1332-

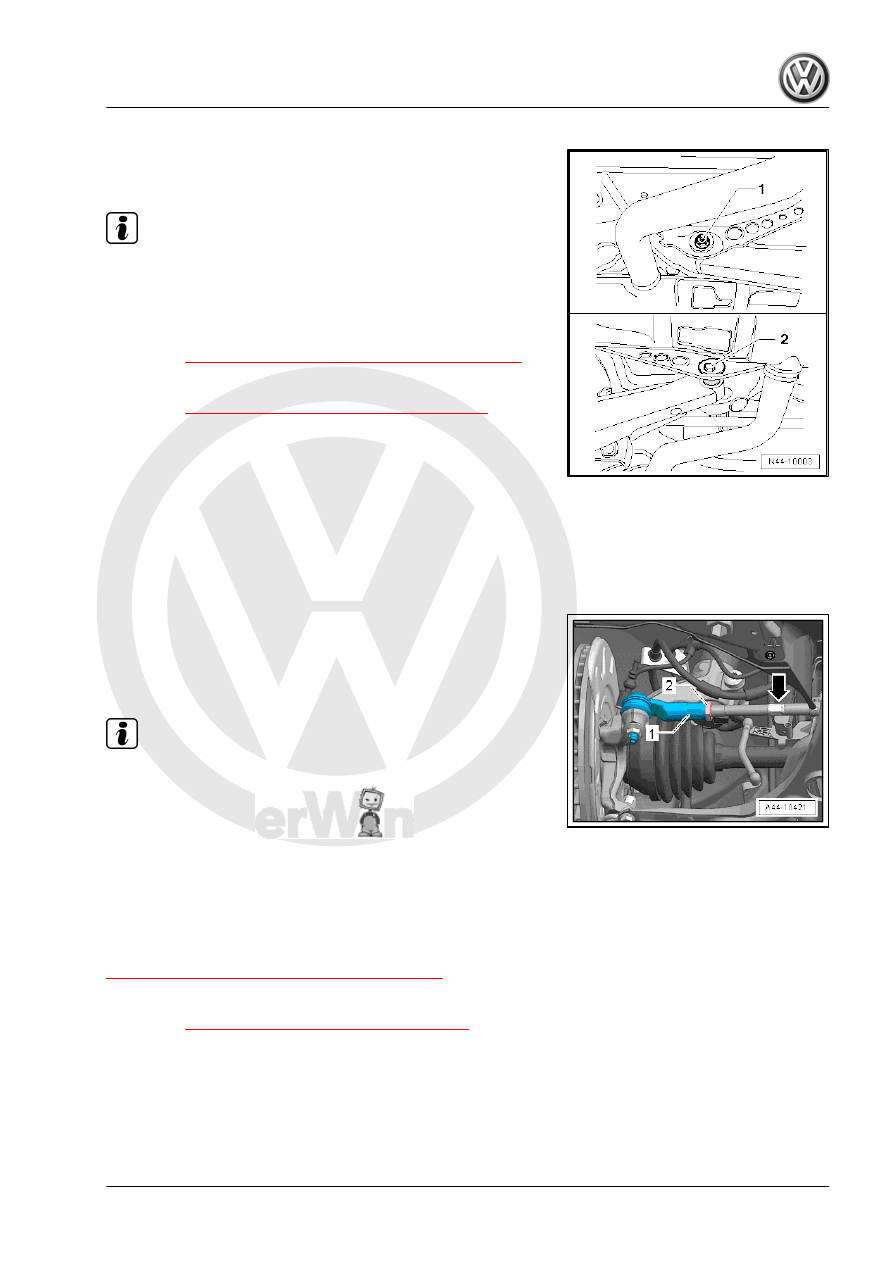

– Loosen nut -1-.

– Turn the eccentric bolt -2- until the specified value is reached.

Note

The maximum adjustment range is 90° to left or right of center

position.

– Tighten the nut -1-.

– After the nut -A- is tightened, check the toe value once more.

⇒ “3.4 Axle Alignment Specified Values”, page 298

Tightening Specifications

♦ Refer to

⇒ “5.1 Overview - Transverse Link”, page 181

3.11

Front Axle Toe, Adjusting

Special tools and workshop equipment required

♦ Torque Wrench 1332 40-200Nm - VAG1332-

♦ Torque Wrench 1332 Insert - Open Ring Wrench - 24mm -

VAG1332/9-

– To loosen or tighten the lock nut -2-, counterhold at the tie rod

end -1- with a suitable tool.

– Loosen the lock nut -2-.

– Adjust toe on left and right–hand wheels at hex -arrow-.

Note

♦

Make sure that boot on steering gear is not damaged or twis‐

ted. Twisted boots wear out quickly.

♦

Only tighten the lock nuts when the vehicle is resting on the

ground - the tie rod end must be parallel to the suspension

strut steering lever.

– Tighten the lock nut -2- and check the toe-in value again.

After tightening the lock nut -2-, it is possible that the value devi‐

ates slightly.

If the measured toe nevertheless lies within the tolerance, the

adjustment is correct. Refer to

⇒ “3.4 Axle Alignment Specified Values”, page 298

.

Tightening Specifications

♦ Refer to

⇒ “3.6 Steering Gear, Servicing”, page 363

3.12

Wheel Run-Out Compensation

A correct toe-in adjustment will not be possible without performing

lateral run-out compensation!

The lateral run–out of the wheel must be compensated for. Oth‐

erwise, measurement will result in false readings.