Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 880

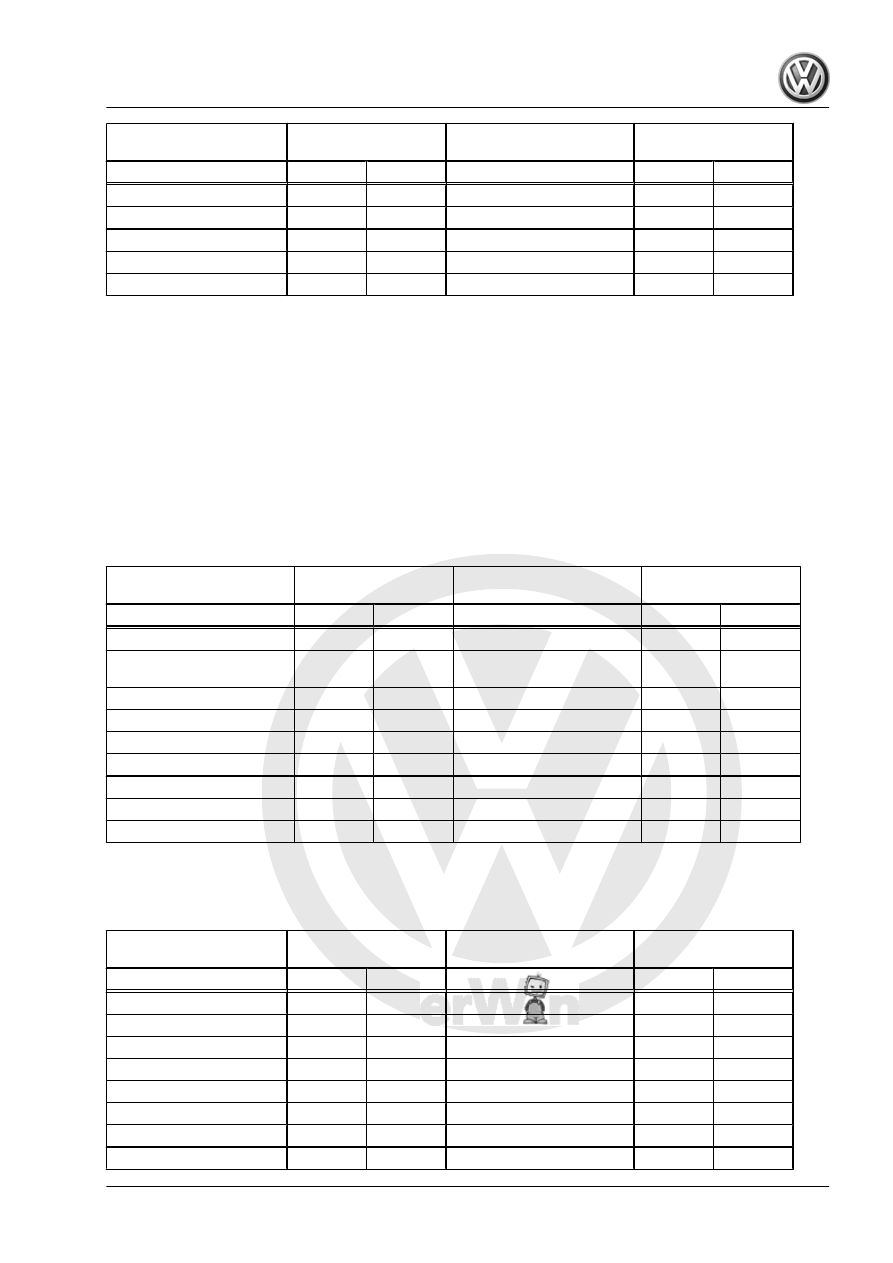

Components Of Front Axle

Removed And Installed

Wheel Alignment

Check Required

Components Of Rear Axle

Removed And Installed

Wheel Alignment

Check Required

Yes

No

Yes

No

Tie rod/tie rod end

X

Axle Beam

X

Steering Gear

X

Subframe

)

Suspension Strut

X

Stabilizer Bar

)

11) Requirement: Subframe and brackets were secured before removal.

3.6.2

Evaluating Need for Axle Alignment,

Multi-Link Suspension

When Vehicle Alignment is Necessary

♦ Vehicle shows handling problems.

♦ There is an accident damage and components were replaced.

♦ Axle components have been removed or replaced.

♦ Tire wear patterns are uneven.

Components Replaced

Front Axle Component Re‐

placed

Wheel Alignment

Check Required

Rear Axle Component Re‐

placed

Wheel Alignment

Check Required

Yes

No

Yes

No

Lower Control Arm

X

Lower transverse link

X

Bonded rubber bushings

for control arm

X

Upper Transverse Link

X

Wheel bearing housing

X

Tie rod

X

Tie rod/tie rod end

X

Wheel bearing housing

X

Steering Gear

X

Subframe

X

Subframe

X

Coil Spring

X

Suspension Strut

X

Shock Absorber

X

Stabilizer Bar

X

Stabilizer Bar

X

Trailing Arm

X

12) Requirement: Subframe and brackets were secured before removal.

Components Removed and Installed

Components Of Front Axle

Removed And Installed

Wheel Alignment

Check Required

Components Of Rear Axle

Removed And Installed

Wheel Alignment

Check Required

Yes

No

Yes

No

Lower Control Arm

)

Lower transverse link

X

Wheel bearing housing

X

Upper Transverse Link

X

Tie rod/tie rod end

X

Tie rod

X

Steering Gear

X

Wheel bearing housing

X

Subframe

)

Subframe

X

Suspension Strut

X

Coil Spring

X

Stabilizer Bar

)

Shock Absorber

X

Stabilizer Bar

X