Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 879

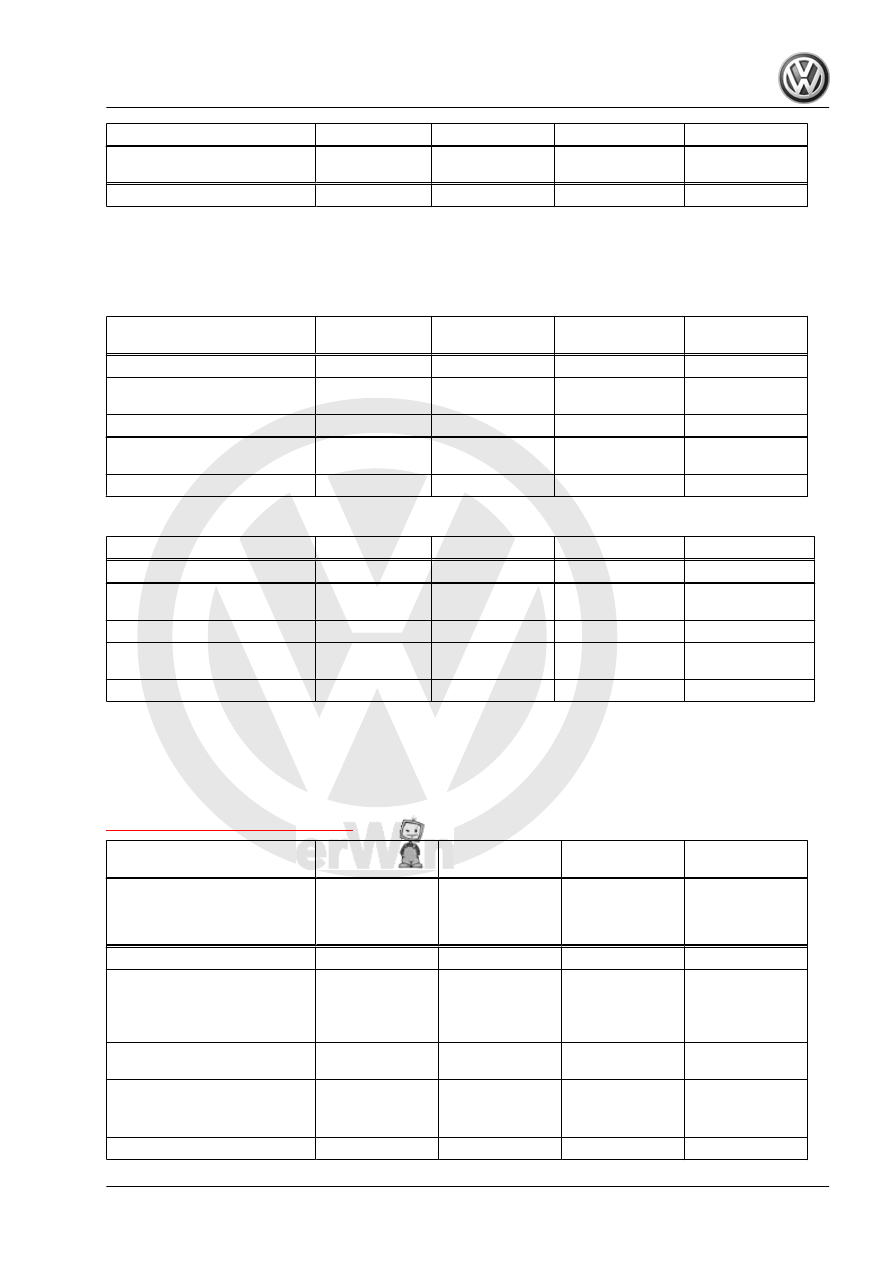

Front Axle

GTI

GTI Heavy Duty

PR numbers

G05, G06+2UC

G09, G06+2UJ

G06, G06+2UN

Standing height

368 ± 10 mm

383 ± 10 mm

5) Camber corrections are not possible. It can only be slightly corrected by push‐

ing the subframe.

6) The toe angle difference can also be indicated negatively in alignment com‐

puter, depending on manufacturer.

Rear Axle

Basic Suspen‐

sion

Sport Suspen‐

sion

Raised Suspen‐

sion

DCC Suspension

Camber

-1° 20′ ± 30′

-1° 20′ ± 30′

-1° 20′ ± 30′

-1° 20′ ± 30′

Maximum permissible differ‐

ence between both sides

maximum 30'

maximum 30'

maximum 30'

maximum 30'

Total toe (at specified camber)

10′ ± 10′

10′ ± 10′

10′ ± 10′

10′ ± 10′

Maximum permissible devia‐

tion from direction of rotation

maximum 20′

maximum 20′

maximum 20′

maximum 20′

Standing height

385 ± 10 mm

370 ± 10 mm

400 ± 10 mm

375 ± 10 mm

Rear Axle

GTI

GTI Heavy Duty

Camber

-1° 45′ ± 30′

-1° 20′ ± 30′

Maximum permissible differ‐

ence between both sides

maximum 30'

maximum 30'

Total toe (at specified camber)

16′ ± 10′

10′ ± 10′

Maximum permissible devia‐

tion from direction of rotation

maximum 20′

maximum 20′

Standing height

370 ± 10 mm

385 ± 10 mm

3.4.4

Axle Alignment Specified Values, Multi-Link Suspension, Golf Wagon

Specified values valid for all engine versions.

PR number explanations. Refer to

⇒ “3.7 Vehicle Data Label”, page 306

Front Axle

Basic Suspen‐

sion

Sport Suspen‐

sion

Raised Suspen‐

sion

DCC Suspension

PR numbers

G07, G01+0N4

+2UA,

G15, G07+0N4

+2UA

G08, G01+0N4

+2UA

G11, G01+0N4

+2UF,

G17, G07+0N4

+2UF

G04, G03+2UH

Total toe (wheels not pressed)

10′ ± 10′

10′ ± 10′

10′ ± 10′

10′ ± 10′

Camber (wheels in straight-

.

-30′ ± 30′

-41′ ± 30′

-16′ ± 30′

-36′ ± 30′

Maximum permissible differ‐

ence between both sides

maximum 30'

maximum 30'

maximum 30'

maximum 30'

Toe differential angle at 20°

steering angle. Refer to

1° 19′ ± 20′

1° 30′ ± 20′

1° 09′ ± 20′

1° 26′ ± 20′

Caster

7° 23′ ± 30′

7° 38′ ± 30′

7° 09′ ± 30′

7° 33′ ± 30′

Maximum permissible differ‐

ence between both sides

maximum 30'

maximum 30'

maximum 30'

maximum 30'

Standing height

383 ± 10 mm

368 ± 10 mm

398 ± 10 mm

373 ± 10 mm