Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 649

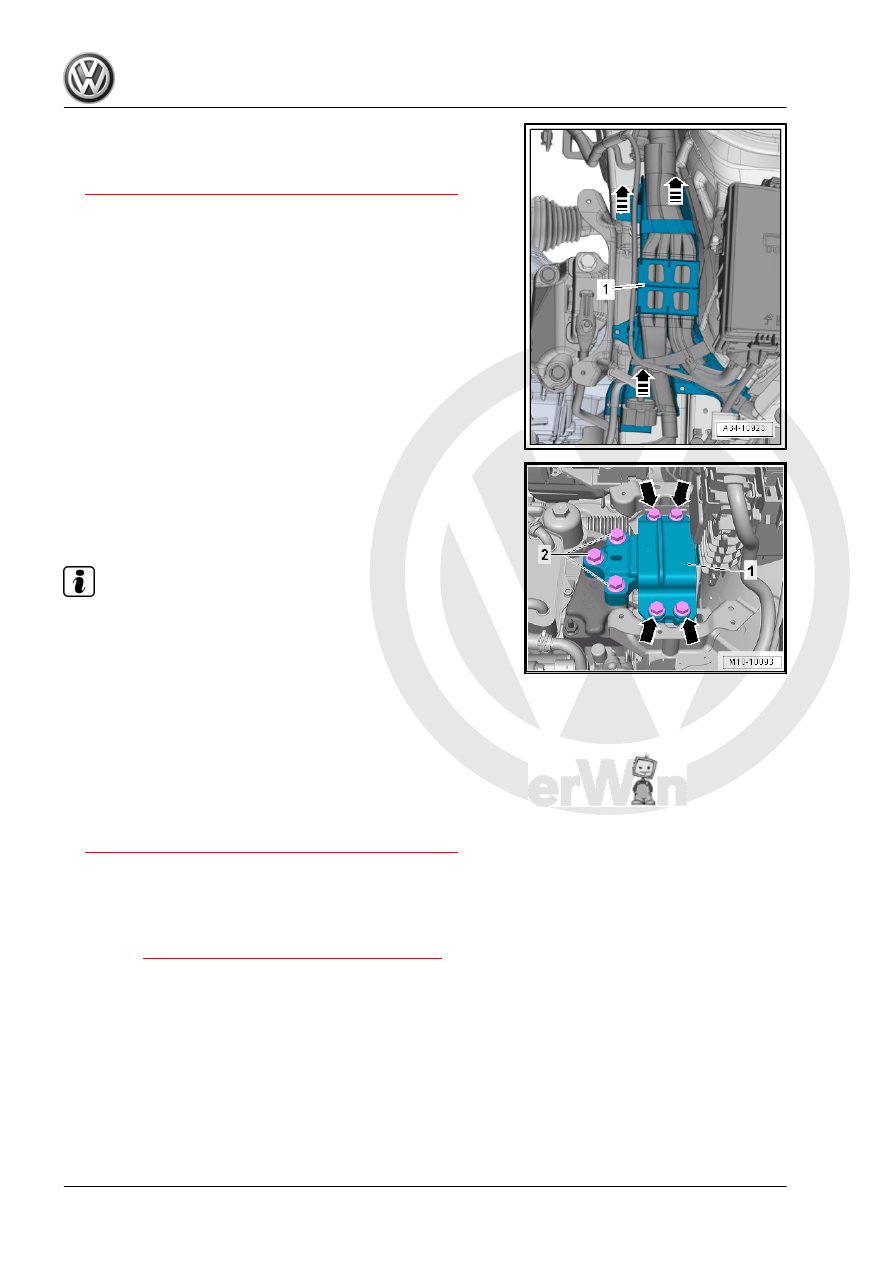

– Unclip the wiring guide -1- upward and move it slightly to the

side in direction of -arrows-.

– Support the engine in its installed position. Refer to

⇒ “2.5 Engine, Supporting in Installed Position”, page 33

.

– Remove the bolts -2-, then the bolts -arrows- and remove the

transmission mount -1-.

Installing

Install in reverse order of removal. Note the following:

Note

♦

Replace the bolts which have been tightened to torque.

♦

The transmission support and the transmission mount support

arm must be absolutely parallel to each other before installing

bolts. Push the transmission up using a floor jack if necessary.

– Secure the transmission support to the longitudinal member.

– Pull the transmission up using the spindle on the engine sup‐

port bridge until the transmission support touches the trans‐

mission mount support arm.

– Install bolts by hand pay attention while doing so that the bolts

are not installed crooked.

– Check the adjustment of the assembly mounts. Refer to

⇒ “2.7 Subframe Mount, Checking Adjustment”, page 37

.

– When the bolts are tightened to the tightening specification,

remove the Engine Support Bridge - 10-222A- from the en‐

gine.

Tightening Specifications

♦ Refer to

⇒ “2.1 Overview - Subframe Mount”, page 29

♦ Refer to ⇒ Electrical Equipment; Rep. Gr. 27 ; Battery; Over‐

view - Battery .