Volkswagen Golf / Golf GTI / Golf Variant. Service manual - part 647

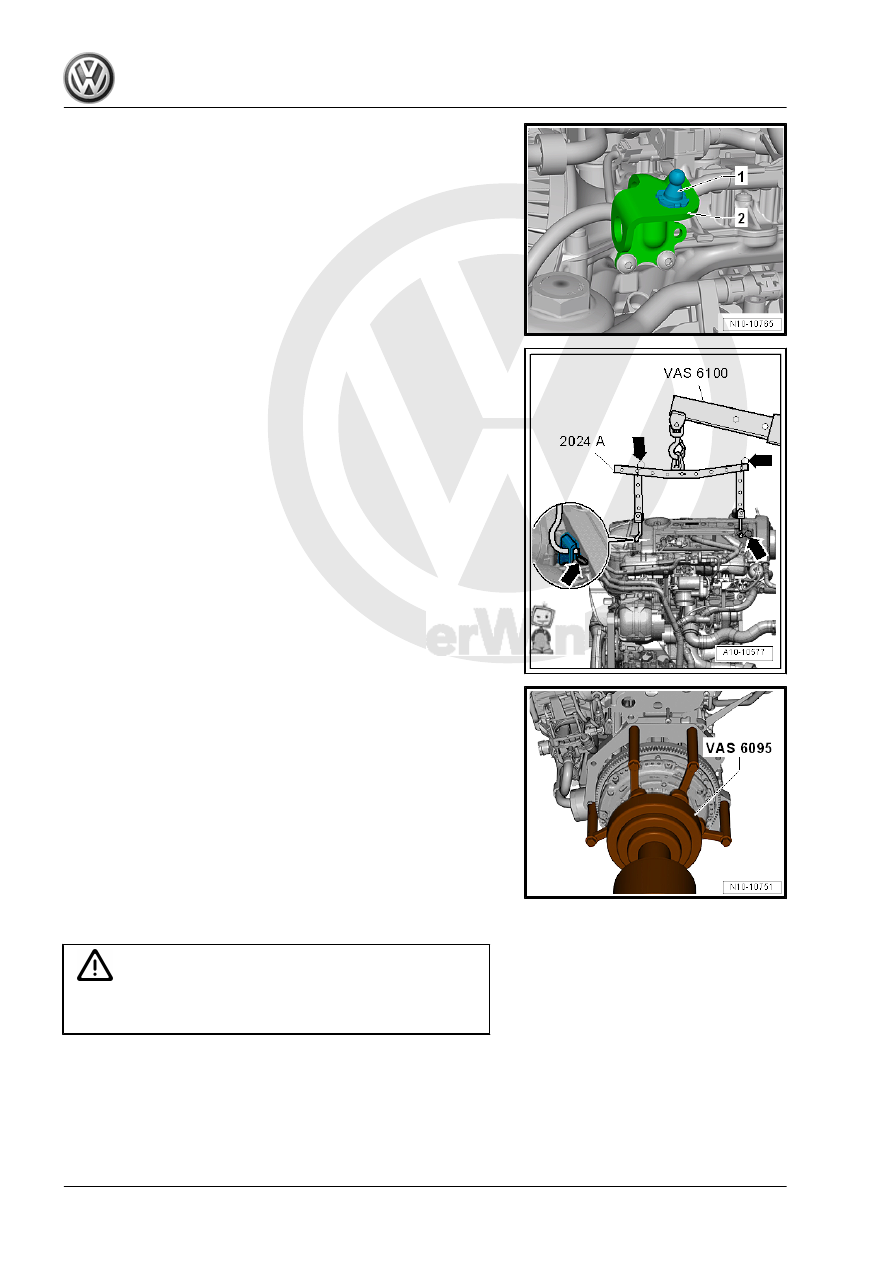

– Unclip the right engine cover mount -1-.

– Hook the Engine Sling - 2024A- to the engine and to the Shop

Crane - VAS6100- .

– To be aligned to the center of gravity of the engine assembly,

the hole rails must be inserted as shown in the illustration.

– Secure the mounting hooks and pins on the engine support

bridge using securing pins -arrows-.

– Lower the engine from the Engine and Gearbox Jack -

VAS6931- using the Shop Crane - VAS6100- .

– Remove the transmission alignment sleeve and secure the

transmission side of the engine on the Engine And Transmis‐

sion Holder - VAS6095- .

1.4

Engine, Installing

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Bolts - Transmission Mount

♦ Bolts - Engine to Transmission