Toyota Corolla (2004+). Manual - part 93

14-110

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

Transverse Engine

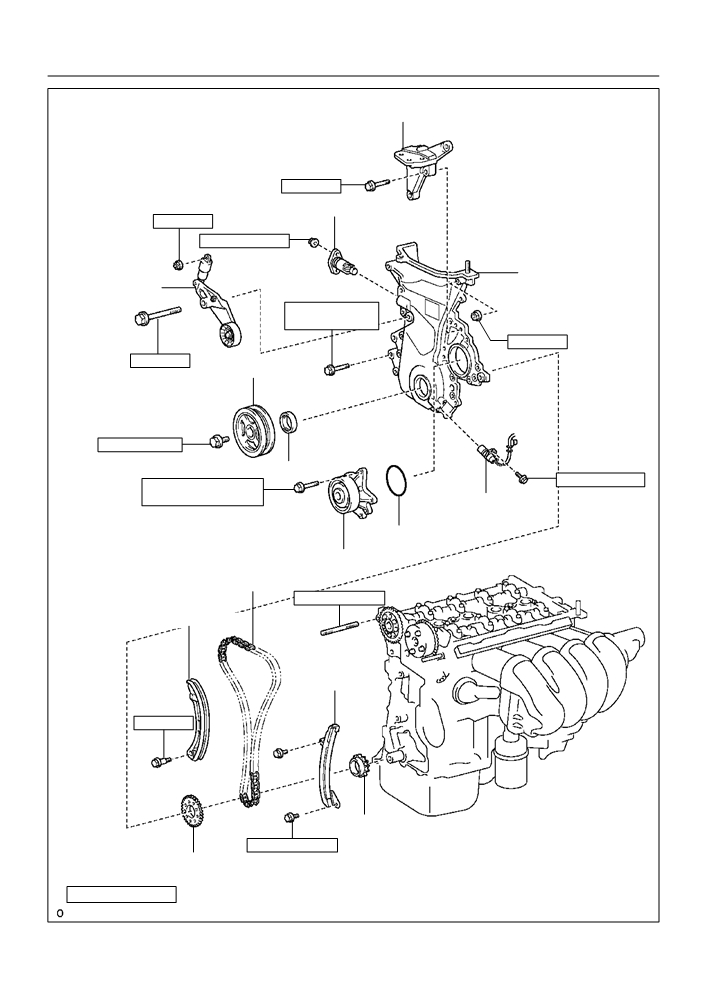

Engine Mounting Bracket

47 (479, 35)

Chain Tensioner Assy No. 1

29 (296, 21)

9.0 (92, 80 in. lbf)

Timing Chain or

V-ribbed Belt

Belt Cover Sub-assy

Tensioner Assy

13 (133, 10) (M6)

19 (194, 14) (M8)

13 (133, 10)

69 (704, 51)

Crankshaft Pulley

138 (1,047, 102)

_ Oil Seal

9.0 (92, 80 in. lbf)

9 (92, 80 in. lbf1) (L=20)

11 (112, 8) (L=35)

Crank Position Sensor

_ O-ring

Water Pump Assy

Chain Sub-assy

9.5 (97, 84 in. lbf)

Chain Tensioner Slipper

Chain Vibration

Damper No. 1

19 (194, 14)

Crankshaft timing Sprocket

9.0 (92, 80 in. lbf)

Crankshaft Position Sensor

Plate No. 1

N·m (kgf·cm, ft·lbf)

: Specified torque

_ Non-reusable part

A60628

14-111

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

Camshaft Bearing Cap No. 1

13 (133, 10)

23 (235, 17)

Camshaft Bearing Cap No. 3

Camshaft No. 2

Camshaft

See page 14-112

1st 49 (500, 36)

2nd Turn 90 F

Plate Washer

Cylinder Head Sub-assy

_ O-ring

_ Gasket

Camshaft Timing Oil Control Valve Assy

9.0 (92, 80 in. lbf)

Intake Manifold

_ Cylinder Head Gasket

49 (500, 36)

Clamp Bracket

Manifold Stay

13 (133, 10)

30 (306, 22)

9.0 (92, 80 in. lbf)

Oil Level Gage

Sub-assy

Oil Level Gage Guide

_ O-ring

N·m (kgf·cm, ft·lbf)

: Specified torque

_ Non-reusable part

A64046

14-112

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

140OL-01

REPLACEMENT

1.

WORK FOR PREVENTING GASOLINE FROM SPILLING OUT (See page 11-1)

2.

REMOVE ENGINE UNDER COVER RH

3.

DRAIN COOLANT (See page 16-7)

4.

REMOVE FRONT WHEEL RH

5.

REMOVE CYLINDER HEAD COVER NO.2

(a) Remove the 2 nuts, 2 clips and cylinder head cover.

A65077

6.

REMOVE AIR CLEANER HOSE NO.1

(a) Loosen the 2 air cleaner hose clamp bolts, and remove the air cleaner hose.

7.

SEPARATE ACCELERATOR CONTROL CABLE ASSY

(a) Loosen the nut, and remove the accelerator control cable from the accelerator control cable bracket.

8.

DISCONNECT WATER BY-PASS HOSE

(a) Disconnect the water by-pass hose from the throttle body.

9.

DISCONNECT WATER BY-PASS HOSE NO.2

(a) Disconnect the water by-pass hose from the throttle body.

10. REMOVE EFI FUEL PIPE CLAMP (See page 11-10)

11. DISCONNECT FUEL TUBE SUB-ASSY (See page 11-10)

SST

09268-21010

12. DISCONNECT UNION TO CONNECTOR TUBE HOSE

(a) Disconnect the union to connector tube hose from the hose to hose tube.

13. DISCONNECT RADIATOR HOSE INLET

(a) Disconnect radiator hose inlet from the cylinder head.

14. DISCONNECT HEATER INLET WATER HOSE

(a) Disconnect the heater inlet water hose from the cylinder head.

15. REMOVE FAN AND GENERATOR V BELT

(a) Turn the V-ribbed belt tensioner slowly clockwise and

loosen it. Then, remove the fan and generator V belt and

put back the V-ribbed belt tensioner little by little and fix

it quietly.

A60622

14-113

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

16. SEPARATE VANE PUMP ASSY (See page 51-8)

NOTICE:

Do not disconnect the hose.

17. REMOVE GENERATOR ASSY (See page 19-16)

18. SEPARATE EXHAUST PIPE ASSY FRONT

(a) Remove the 2 bolts, 2 compression spring installing the front side of exhaust pipe.

(b) Remove the gasket.

19. REMOVE ENGINE MOUNTING INSULATOR

SUB-ASSY RH

(a) Remove the PS oil pump reservoir and put it aside.

(b) Place a wooden block between the jack and engine, and

set the jack, then remove the 4 bolts, the 2 nuts and en-

gine mounting insulator RH.

A01045

A64005

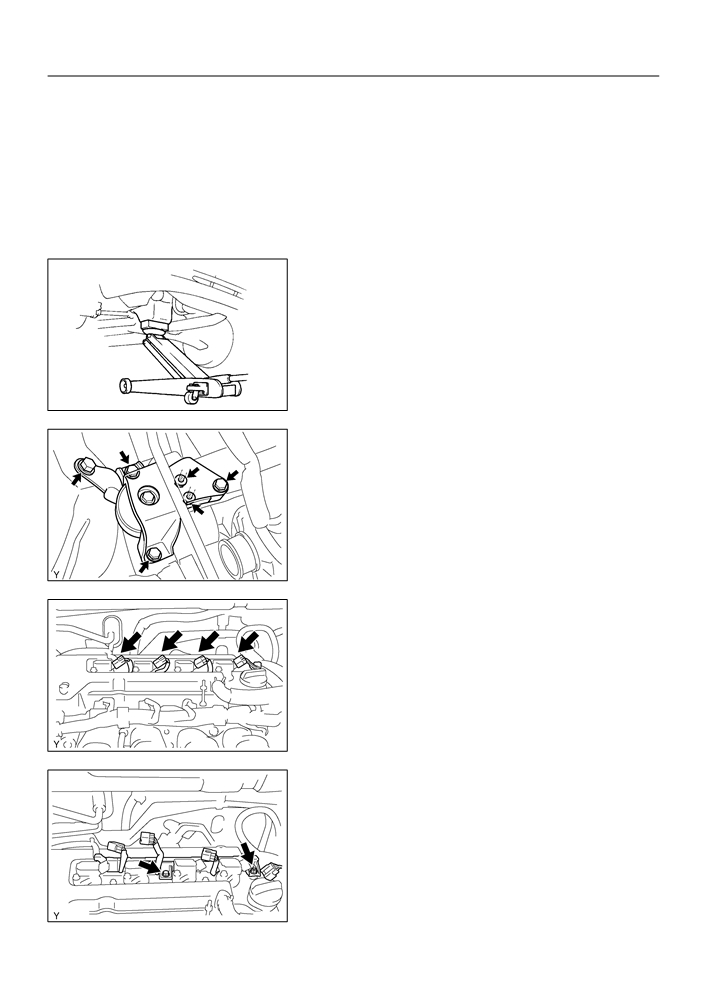

20. DISCONNECT ENGINE WIRE

(a) Remove the 5 clamps from the 5 clamp brackets.

(b) Disconnect the 4 ignition coil connectors.

A64021

(c)

Remove the bolt and nut installing the engine wire.

A64022

14-114

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

21. REMOVE IGNITION COIL ASSY

(a) Remove the 4 bolts and 4 ignition coils.

A64023

22. DISCONNECT VENTILATION HOSE

(a) Disconnect the ventilation hose from the cylinder head

cover.

A65078

23. DISCONNECT VENTILATION HOSE NO.2

(a) Disconnect the ventilation hose from the cylinder head

cover.

A64058

24. REMOVE CYLINDER HEAD COVER SUB-ASSY

(a) Remove the 9 bolts, 2 seal washers, 2 nuts, 3 clamp

brackets and cylinder head cover.

A64856

14-115

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

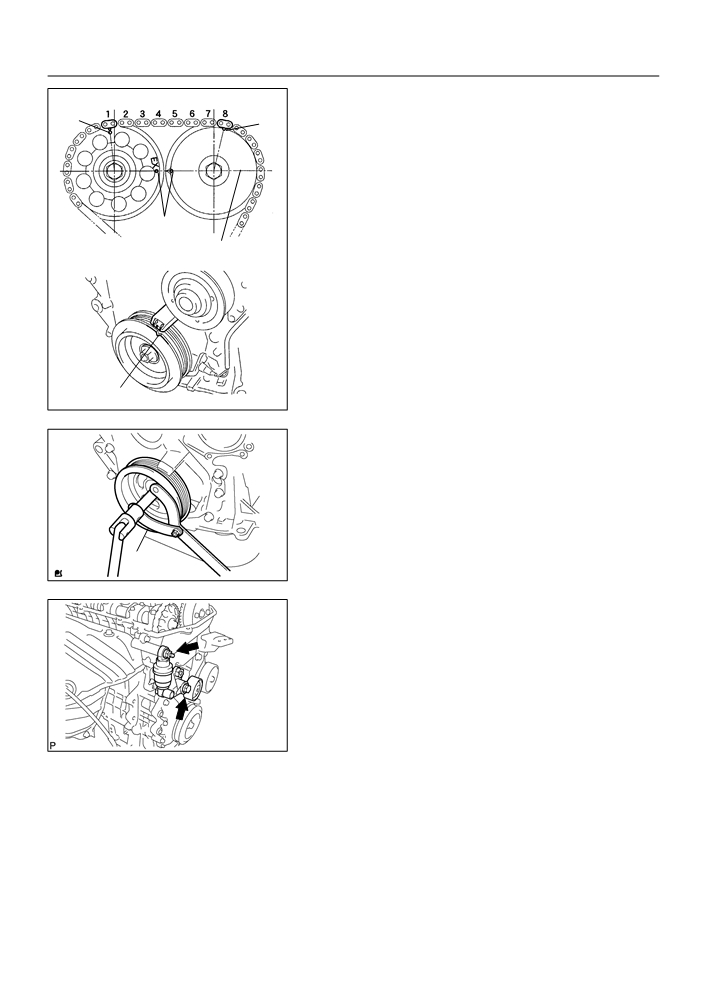

25. SET NO. 1 CYLINDER TO TDC/COMPRESSION

Mark

(a) Turn the crankshaft pulley, and align its groove with timing

Mark

mark ”0” of the timing chain cover.

(b) Check that the point marks of the camshaft timing sprock-

et and VVT timing sprocket are in straight line on the tim-

ing chain cover surface as shown in the illustration.

HINT:

If not, turn the crankshaft 1 revolution (360_) and align the

Mark

marks as above.

Timing Chain

Cover Surface

Groove

A62185

26. REMOVE CRANKSHAFT PULLEY

(a) Using SST, remove the pulley bolt.

SST

09960-10010 (09962-01000, 09963-01000)

(b) Remove the crankshaft pulley from the crankshaft.

SST

A62837

27. REMOVE V-RIBBED BELT TENSIONER ASSY

(a) Remove the bolt, nut and V-ribbed belt tensioner.

HINT:

Handle a jack up and down to remove the bolt.

A11858

28. REMOVE WATER PUMP ASSY (See page 16-8)

14-116

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

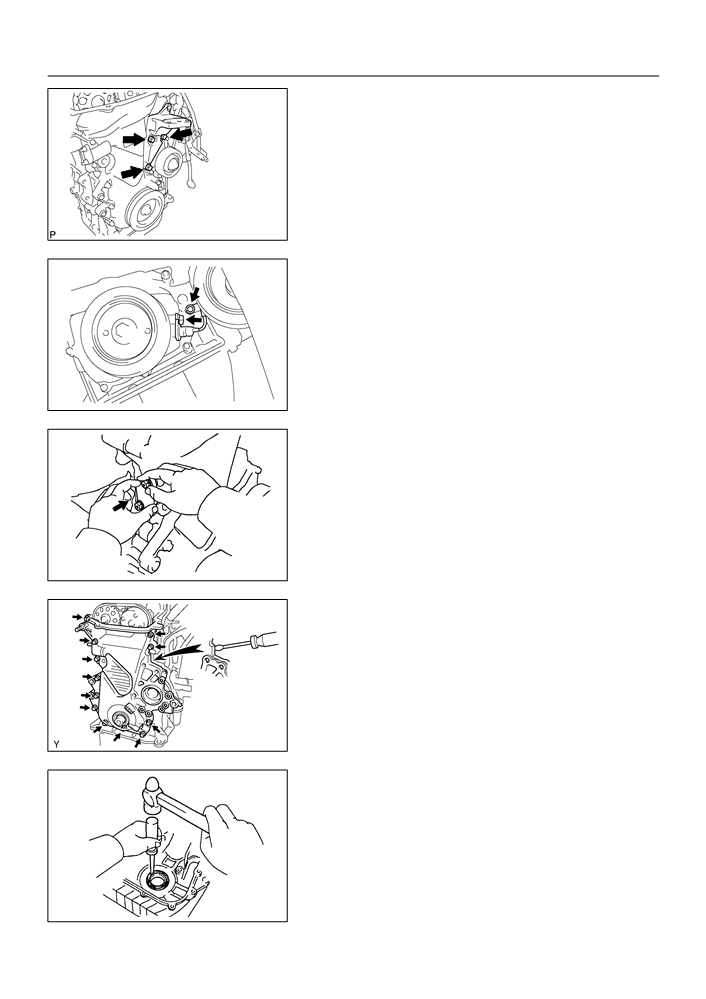

29. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING BRACKET

(a) Remove the 3 bolts and transverse engine engine mount-

ing bracket.

A12816

30. REMOVE CRANK POSITION SENSOR

(a) Remove the 2 bolts installing the crank position sensor.

B00086

31. REMOVE CHAIN TENSIONER ASSY NO.1

(a) Remove the 2 nuts and chain tensioner.

NOTICE:

Be sure not to revolve the crankshaft without the chain ten-

sioner.

Push

A62178

32. REMOVE TIMING CHAIN OR BELT COVER

SUB-ASSY

(a) Remove the 11 bolts and nuts.

(b) Using a torx wrench socket (E8), remove the stud bolt.

(c)

Remove the timing chain cover by prying the portions be-

tween the cylinder head and cylinder block with a screw-

driver.

NOTICE:

A10076

Be careful no tot damage the contact surfaces of the timing

chain cover, cylinder head and cylinder block.

33. REMOVE TIMING GEAR COVER OIL SEAL

(a) Using a screwdriver, remove the oil seal.

A30848

14-117

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

34.

REMOVE CRANKSHAFT POSITION SENSOR PLATE NO.1

35.

REMOVE CHAIN TENSIONER SLIPPER

(a)

Remove the bolt and chain tensioner slipper.

36.

REMOVE CHAIN VIBRATION DAMPER NO.1

(a)

Remove the 2 bolt and chain vibration damper.

37. REMOVE CHAIN SUB-ASSY

(a) Remove the timing chain with the crankshaft timing gear

plying screwdrivers as shown in the illustration.

NOTICE:

F

Put shop rag to protect the engine.

F

In case of revolving the camshafts with the chain off

the sprockets, turn the crankshaft 1/4 revolution for

valves not to touch the pistons.

A30857

38. REMOVE INTAKE MANIFOLD

(a) Disconnect the 2 water hoses from the throttle body.

(b) Disconnect the 2 vacuum hoses from the intake man-

ihold.

(c)

Remove the 4 bolts, 2 nuts, 2 wire brackets, the intake

manihold and throttle body assembly.

(d) Remove the gasket from the intake manihold and throttle

body assembly.

A14660

39.

REMOVE OIL LEVEL GAGE SUB-ASSY

(a)

Remove the oil level gage from the oil level gage guide.

40. REMOVE OIL LEVEL GAGE GUIDE

(a) Remove the bolt and oil level gage guide.

A64026

41. SEPARATE WATER BY-PASS PIPE NO.1

(a) Remove the 2 bolts installing the water by-pass pipe.

14-118

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

42. REMOVE CAMSHAFT

2

4

5

3

1

(a) Uniformly loosen and remove the 19 bearing cap bolts, in

several passes, in the sequence shown, and remove the

9 bearing caps, intake and exhaust camshafts.

A62814

43. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSY

(a) Remove the bolt and camshaft timing oil control valve.

B06777

44. REMOVE MANIFOLD STAY

(a) Remove the 3 bolts and manifold stay.

A64030

45. REMOVE CYLINDER HEAD SUB-ASSY

3

7

9

6

2

(a) Using a 10 mm bi-hexagon wrench, uniformly loosen and

remove the 10 cylinder head bolts, in several passes, in

the sequence shown, and remove the 10 cylinder head

bolts and 10 plate washers.

(b) Remove the cylinder head.

1

5

10

8

4

A62816

46. REMOVE CYLINDER HEAD GASKET

14-119

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

47. INSTALL CYLINDER HEAD GASKET

Lot No.

(a) Place a new cylinder head gasket on the cylinder block

surface with the Lot No. stamp upward.

NOTICE:

F

Pay attention to the installation direction.

F

Place the cylinder head quietly in order not to damage

the gasket with the bottom part of the head.

A62827

48. INSPECT CYLINDER HEAD SET BOLT

(a) Using a vernier calipers, measure the length of cylinder

Overall Length

head bolt from the seat to the end.

Standard length: 146.8 - 148.2 mm (5.780 - 5.835 in.)

Maximum length: 148.5 mm (5.846 in.)

If the length surpasses the maximum, replace the bolt.

A62820

49. INSTALL CYLINDER HEAD SUB-ASSY

8

4

2

5

9

HINT:

The cylinder head bolts are tightened in 2 progressive steps.

(a) Apply a light coat of engine oil on the threads and under

the heads of the cylinder head bolts.

(b) Using a 10 mm bi-hexagon wrench, install and uniformly

tighten the 10 cylinder head bolts and plate washers, in

several passes, in the sequence shown.

10

6

1

3

7

A62816

Torque: 49 N m (500 kgf cm, 36 ft lbf)

(c)

Make the front of the cylinder head bolt with paint.

Paint Mark

90_

(d) Retighten the cylinder head bolts 90_ in the numerical or-

der shown.

Front

(e) Check that the point marked bolts are moved at 90_

angle.

A62823

50. INSTALL MANIFOLD STAY

(a) Install the manifold stay with 3 bolts.

Torque: 49 N m (500 kgf cm, 36 ft lbf)

A64030

14-120

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

51. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE

ASSY

(a) Apply a light coat of engine oil on a new O-ring, and install

it to the camshaft timing oil control valve.

(b) Install the camshaft timing oil control valve with the bolt.

Torque: 9.0 N m (92 kgf cm, 80 in. lbf)

B06777

52. INSTALL CAMSHAFT

(a) Apply a light coat of engine oil on the camshaft journals.

(b) Place the 2 camshafts on the cylinder head with the No.

1 cam lobes facing as shown the illustration.

A62150

(c)

Examine the front marks and numbers and tighten the

6

2

4

8

bolts in the order shown in the illustration.

Torque:

11

Bearing cap No. 1 23 N m (235 kgf cm, 17 ft lbf)

10

Bearing cap No. 3 13 N m (133 kgf cm, 10 ft lbf)

9

5

1

3

7

A62825

53. INSTALL WATER BY-PASS PIPE NO.1

(a) Install the water by-pass pipe with the 2 bolts.

Torque: 9.0 N m (92 kgf cm, 80 in. lbf)

54. INSTALL OIL LEVEL GAGE GUIDE

(a) Apply a light coat of engine oil on a new O-ring, and install

it to the oil level gage guide.

(b) Install the oil level gage guide with the bolt.

Torque: 13 N m (133 kgf cm, 10 ft lbf)

A64026

14-121

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

55. INSTALL INTAKE MANIFOLD

(a) Install a new gasket to the intake manifold.

(b) Install the intake manifold and throttle body assembly with

the 2 brackets, 4 bolts and 2 nuts. Uniformly tighten the

bolts and nuts in several passes.

Torque: 30 N m (306 kgf cm, 22 ft lbf)

(c)

Connect the 2 vacuum hoses to the intake manifold.

(d) Connect the 2 water hoses to the throttle body.

A14660

56. INSTALL CHAIN SUB-ASSY

(a) Set No. 1 cylinder to TDC/compression.

(1)

Turn the hexagonal wrench head portion of the

camshafts, and align the point marks of the cam-

shaft timing sprockets.

A10079

(2)

Using a crankshaft pulley bolt, turn the crankshaft

Upward

Set Key

and set the set key on the crankshaft upward.

A62170

(b) Install the timing chain on the crankshaft timing sprocket

Yellow

with the yellow color link aligned with the timing mark on

Color Line

the crankshaft timing sprocket.

HINT:

Three yellow color links are on the chain.

Timing Mark

A62171

(c)

Using SST, install the crankshaft timing sprocket.

SST

09223-22010

SST

A62172

14-122

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

Yellow Color Mark

(d) Install the timing chain on the camshaft timing sprockets

with the yellow color links aligned with the timing marks on

the camshaft timing sprockets.

Timing Mark

A62173

57. INSTALL CHAIN VIBRATION DAMPER NO.1

(a) Install the chain vibration damper with the 2 bolts.

Torque: 9.0 N m (92 kgf cm, 80 in. lbf)

58. INSTALL CHAIN TENSIONER SLIPPER

(a) Install the chain tensioner slipper with the bolt.

Torque: 19 N m (194 kgf cm, 14 ft lbf)

59. INSTALL CRANKSHAFT POSITION SENSOR PLATE

NO.1

(a) Install the plate with the ”F” mark facing forward.

A30867

60. INSTALL TIMING GEAR COVER OIL SEAL

(a) Apply MP grease to a new oil seal lip.

SST

(b) Using SST, tap in the oil seal until its surface is flush with

the timing chain cover edge.

SST

09223-22010

NOTICE:

Keep the lip off foreign materials.

A62174

14-123

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

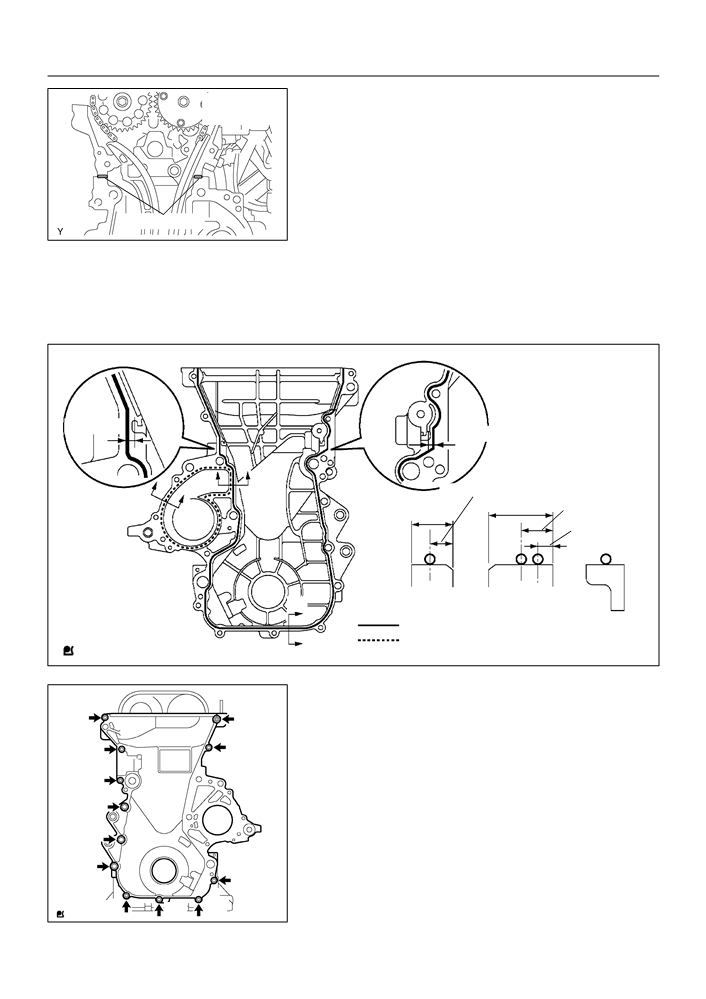

61. INSTALL TIMING CHAIN OR BELT COVER SUB-ASSY

Seal Width

(a) Remove any old packing material from the contact sur-

4 - 5 mm

face.

(b) Apply seal packing in the shape of bead (Diameter 3.5

mm - 4.5 mm (0.1379 - 0.177 in.)) consequently as

shown in the illustration.

Seal packing:

Water pump part part No. 08826-00100 or equivalent

Seal Packing

A62175

Other part part No. 08826-00080 or equivalent.

NOTICE:

F

Remove any oil from the contact surface.

F

Install the oil pan within 3 minutes after applying seal

packing.

F

Do not put into engine oil within 2 hours after instal-

ling.

Timing Chain Cover side:

3 (0.118)

3 (0.118)

B

B

4.5

(0.177)

A

12 (0.472)

6 (0.236)

A

7 (0.276)

3 (0.118)

Width 4 (0.157)

A - A

B - B

C

08826-00100 or equivalent

C - C

08826-00080 or equivalent

(mm (in.))

C

A65676

(c)

Install the timing chain cover with the 11 bolts and nut.

Torque:

A

A

A 13 Nm (133 kgf cm, 10 ft lbf)

B 19 Nm (194 kgf cm, 14 ft lbf)

A

A

(d) Using a torx wrench socket (E8), install the stud bolt.

Torque: 9.5 N m (97 kgf cm, 84 in. lbf)

A

B

B

B

A

A

A

A

A65677

14-124

ENGINE MECHANICAL

- CYLINDER HEAD GASKET

62. INSTALL CHAIN TENSIONER ASSY NO.1

(a) Check the O-ring is clean, and set the hook as shown in

Raise

the illustration.

Push

Hook

Pin

A62177

(b) Apply engine oil to the chain tensioner and install it withe

2 nuts.

Torque: 9.0 N m (92 kgf cm, 80 in. lbf)

NOTICE:

When installing the tensioner, set the hook again if the

Push

hook release the plunger.

A62178

63. INSTALL CRANK POSITION SENSOR

(a) Install the crank position sensor with the 2 bolts.

Torque: 9.0 N m (92 kgf cm, 80 in. lbf)

B00086

64. INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

BRACKET

(a) Install the transverse engine engine mounting bracket

with the 3 bolts.

Torque: 47 N m (479 kgf cm, 35 ft lbf)

A12816

65. INSTALL WATER PUMP ASSY (See page 16-8)