Toyota Corolla (2004+). Manual - part 39

05-309

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

WIRING DIAGRAM

Skid Control ECU

with Actuator

13

R

S1

FL+

2

A3

ABS Speed Sensor

Front LH

26

1

G

S1

FL-

27

B

S1

FR+

2

A4

ABS Speed Sensor

Front RH

28

1

W

S1

FR-

F40884

INSPECTION PROCEDURE

HINT:

Start the inspection from step 1 in case of using the hand-held tester and start from step 2 in case of not

using the hand-held tester.

1

READ VALUE OF HAND-HELD TESTER(FRONT SPEED SENSOR)

(a) Select the DATALIST mode on the hand-held tester.

(b) Check that there is no difference between the speed value output from the speed sensor displayed

by the hand-held tester and the speed value displayed by the speedometer when driving the vehicle.

OK:

There is almost no difference in the displayed speed value.

HINT:

There is tolerance of

10 % in the speedometer indication.

OK Go to step 5

NG

05-310

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

2

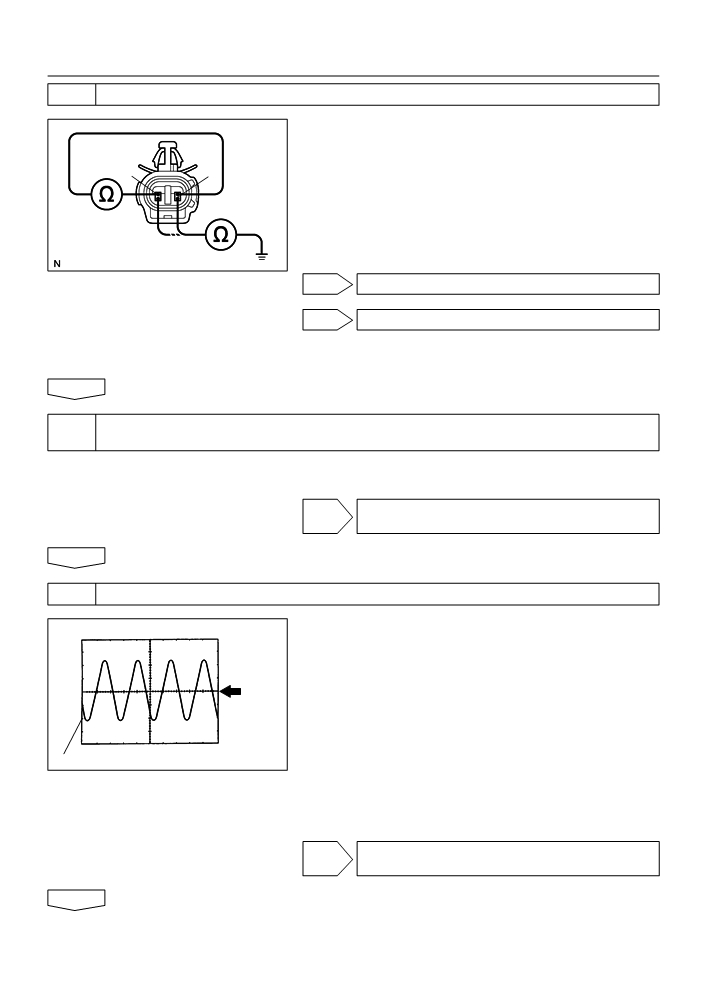

INSPECT FRONT SPEED SENSOR

(a) Remove the fender liner.

(b) Disconnect the speed sensor connector.

(c)

Measure resistance between terminals 1 and 2 of the

2

1

speed sensor connector.

OK: 0.6 - 2.5 k W or 0.9 - 1.8 k W at 20_C

(d) Measure resistance between each of terminals 1 and 2 of

speed sensor connector and body ground.

OK:

C93876

Resistance: 1 M W or higher

NG REPLACE SPEED SENSOR FRONT RH

NG REPLACE SPEED SENSOR FRONT LH

NOTICE:

Check the speed sensor signal last (See page

05-297).

OK

3

CHECK HARNESS AND CONNECTOR(FRONT SPEED SENSOR - SKID CONTROL

ECU)

(a) Check for open and short circuit in harness and connector between each front speed sensor and skid

control ECU (See page 01-30).

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

4

INSPECT SPEED SENSOR AND SENSOR ROTOR SERRATIONS

(REFERENCE) INSPECTION USING OSCILLOSCOPE

Normal Signal Waveform

(a) Connect the oscilloscope to the terminal FR+ - FR- and

FL+ - FL- of the skid control ECU.

(b) Drive the vehicle at about 30 km/h (19 mph), and check

GND

the signal waveform.

HINT:

F

As the vehicle speed (wheel revolution speed) increases,

a cycle of the waveform becomes shorter and the fluctua-

2 m/s / Division

W04200

tion in the output voltage becomes greater.

1 V / Division

F

When noise is identified in the waveform on the oscillo-

scope, error signals are generated due to the speed sen-

sor rotor’s scratches, looseness or foreign matter depos-

ited on it.

OK CHECK AND REPLACE BRAKE ACTUATOR

ASSY

NG

05-311

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

5

INSPECT FRONT SPEED SENSOR INSTALLATION

(a) Check the speed sensor installation.

OK:

The installation bolt is tightened properly and there is

no clearance between the sensor and front steering

knuckle.

Torque: 8.0 N m (82 kgf cm, 71 in. lbf)

OK

NG

BR3795

NG REPLACE SPEED SENSOR FRONT RH

NG REPLACE SPEED SENSOR FRONT LH

NOTICE:

Check the speed sensor signal last (See page

05-297).

OK

6

INSPECT SPEED SENSOR TIP

(a) Remove the front speed sensor (See page 32-44).

(b) Check the sensor tip.

OK:

No scratches or foreign objects on the sensor tip.

NG CLEAN OR REPAIR SPEED SENSOR

NOTICE:

Check the speed sensor signal last (See page

05-297).

OK

7

INSPECT SPEED SENSOR ROTOR

(a) Remove the front speed sensor rotor (See page

30-6 ).

(b) Check the sensor rotor serrations.

OK:

No scratches, missing teeth or foreign objects.

HINT:

If foreign matter is attached, remove it and after reassembling,

check the output waveform.

BR3719

NG CLEAN OR REPAIR SPEED SENSOR ROTOR

NOTICE:

Check the speed sensor signal last (See page

05-297).

OK

CHECK AND REPLACE BRAKE ACTUATOR ASSY (See page

05-306)

05-305

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

057UB-04

LOCATION

Brake Fluid Level

Right Front Speed Sensor

Warning Switch

Brake Actuator

(Incluied Skid Control ECU)

Skid Control Sensor

Speed Sensor Rotor

Left Front Speed Sensor

Combination Meter

(ABS Warning Light)

(Brake Warning Light)

Parking Brake Switch

Stop Lamp Switch

Instrument Panel

DLC3

J/B and R/B

F42872

05-297

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

057U9-04

PRE-CHECK

1.

DIAGNOSIS SYSTEM

(a) Release the parking brake lever.

(b) Check the warning lights.

When the ignition switch is turned ON, check that the ABS

warning light and brake warning light goes on for 3 sec.

HINT:

F

When the parking brake is applied or the level of the brake

C92542

fluid is low, the brake warning light is lit.

F

If the indicator check result is not normal, proceed to trou-

bleshooting for the ABS warning light circuit (See page

05-332 or 05-335) or brake warning light circuit (See

page 05-338).

(c)

In case of not using hand-held tester:

Tc

Check the DTC.

(1)

Using SST, it connects terminal Tc and CG of DLC3.

SST

09843-18040

(2)

Turn the ignition switch to ON.

(3)

Read the DTC from the ABS warning light on the

combination meter.

HINT:

CG

C52361

F

If not code appears, inspect the diagnostic circuit or ABS

warning light circuit (See page 05-332 or 05-335).

F

As an example, the blinking patterns for normal code and

Normal Code

codes 11 and 21 are shown on the left.

2 sec.

(4)

Codes are explained in the code table on page

0.25 sec.

05-303.

If

2 or more malfunctions are indicated at the same time, the

0.25 sec.

lowest numbered DTC will be displayed 1st.

ON

(5)

After completing the check, remove the SST from

the DLC3.

OFF

SST

09843-18040

(d) In case of using hand-held tester:

Code 11 and 21

Check the DTC.

0.5 sec.

0.5 sec.

(1)

Read the DTC by following the prompts on the tes-

1.5 sec.

ter screen.

4 sec.

2.5 sec.

HINT:

Please refer to the hand-held tester operator’s manual for fur-

ON

ther details.

(e) In case of not using hand-held tester:

OFF

Code 11

Code 21

Clear DTC.

R01346

(1)

Using SST, it connects the terminal Tc and CG of the

DLC3.

SST

09843-18040

(2)

Turn the ignition switch to ON.

05-298

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

(3)

Clear DTC stored in ECU by depressing the brake

pedal 8 or more times whitin 5 sec.

(4)

Check that the ABS warning light shows the normal

code.

(5)

Remove the SST from the DLC3.

SST

09843-18040

HINT:

Disconnect the battey cable during repairs will not erase the

BR3890

DTC in the ECU.

(f)

In case of using hand-held tester:

Clear the DTC.

(1)

Turn the ignition switch to ON.

(2)

Operate the hand-held tester to erase the codes.

HINT:

Please refer to the hand-held tester operator’s manual for fur-

ther details.

2.

DATA LIST

HINT:

According to the DATA LIST displayed by the Hand-held tester, you can read the value of the switch, sensor,

actuator and so on without parts removal. Reading the DATA LIST as a first step of troubleshooting is one

of the method to shorten the labor time.

(a) Connect the Hand-held tester to the DLC3.

(b) Turn the ignition switch to ON.

(c)

According to the display on tester, read the ”DATA LIST”.

Measurement Item /

Item

Normal Condition

Diagnostic Note

Range (Display)

ABS motor relay / ON or

ABS MOT RELAY

OFF

Solenoid relay / ON or

SOL RELAY

OFF

ON : Brake pedal de-

Stop light switch / ON or

pressed

STOP LIGHT SW

OFF

OFF : Brake pedal re-

leased

ON : Parking brake applied

Parking brake switch / ON

PKB SW

OFF : Parking brake re-

or OFF

leased

BEFORE : No ABS opera-

ABS operation (FR) / BE-

tion (FR)

ABS OPERT FR

FORE or OPERATE

OPERATE : During ABS

operation (FR)

BEFORE : No ABS opera-

ABS operation (FL) / BE-

tion (FL)

ABS OPERT FL

FORE or OPERATE

OPERATE : During ABS

operation (FL)

BEFORE : No ABS opera-

ABS operation (RR) / BE-

tion (RR)

ABS OPERT RR

FORE or OPERATE

OPERATE : During ABS

operation (RR)

BEFORE : No ABS opera-

ABS operation (RL) / BE-

tion (RL)

ABS OPERT RL

FORE or OPERATE

OPERATE : During ABS

operation (RL)

05-299

DIAGNOSTICS

-

ABS WITH EBD SYSTEM (April, 2003)

Measurement Item /

Item

Normal Condition

Diagnostic Note

Range (Display)

Wheel speed sensor (FR)

reading / min.: 0 km/h (0

Speed indicated on

WHEEL SPD FR

Actual wheel speed

MPH, max.: 326 km/h (202

speedometer

MPH)

Wheel speed sensor (FL)

reading / min.: 0 km/h (0

Speed indicated on

WHEEL SPD FL

Actual wheel speed

MPH, max.: 326 km/h (202

speedometer

MPH)

Wheel speed sensor (RR)

reading / min.: 0 km/h (0

Speed indicated on

WHEEL SPD RR

Actual wheel speed

MPH, max.: 326 km/h (202

speedometer

MPH)

Wheel speed sensor (RL)

reading / min.: 0 km/h (0

Speed indicated on

WHEEL SPD RL

Actual wheel speed

MPH, max.: 326 km/h (202

speedometer

MPH)

ECU power supply voltage

NORMAL : 9.5 V or over

IG VOLTAGE

/ NORMAL or TOO LOW

TOO LOW : Below 9.5 V

ABS solenoid (SFRR) ON /

SFRR

OFF

ABS solenoid (SFRH) ON /

SFRH

OFF

ABS solenoid (SFLR) ON /

SFLR

OFF

ABS solenoid (SFLH) ON /

SFLH

OFF

ABS solenoid (SRRR) ON /

SRRR

OFF

ABS solenoid (SRRH) ON

SRRH

/ OFF

ABS solenoid (SRLR) ON /

SRLR

OFF

ABS solenoid (SRLH) ON /

SRLH

OFF

Air bleed support /

AIR BLD SUPPORT

Supported

SUPPORT or NOT SUP

Test mode / NORMAL or

NORMAL : Normal mode

TEST MODE

TEST

TEST : During test mode

Number of DTC recorded /

#CODES

Min.: 0, max.: 19

min.: 0, max.: 255

3.

ACTIVE TEST

HINT:

Performing the ACTIVE TEST using the Hand-held tester allows the relay, actuator and so on to operate

without parts removal. Performing the ACTIVE TEST as a first step of troubleshooting is one of the methods

to shorten the labor time.

It is possible to display the DATA LIST during the ACTIVE TEST.

(a) Connect the Hand-held tester to the DLC3.

(b) Turn the ignition switch to ON.

(c)

According to the display on tester, perform the ”ACTIVE TEST”.

05-300

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

Item

Vehicle Condition / Test Details

Diagnostic Note

Operation of solenoid

SFRR

Turns ABS solenoid (SFRR) ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SFRH

Turns ABS solenoid (SFRH) ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SFLR

Turns ABS solenoid (SFLR) ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SFLH

Turns ABS solenoid (SFLH) ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SRRR

Turns ABS solenoid (SRRR) ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SRRH

Turns ABS solenoid (SRRH) ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SRLR

Turns ABS solenoid (SRLR) ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SRLH

Turns ABS solenoid (SRLH) ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SFRR & SFRH

Turns ABS solenoid SFRR & SFRH ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SFLR & SFLH

Turns ABS solenoid SFLR & SFLH ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SRRH & SRRR

Turns ABS solenoid SRH & SRR ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SRLR & SRLH

Turns ABS solenoid SRLR & SRLH ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SFRH & SFLH

Turns ABS solenoid SFRH & SFLH ON / OFF

(clicking sound) can be

heard

Operation of solenoid

SOL RELAY

Turns ABS solenoid relay ON / OFF

(clicking sound) can be

heard

Operation of motor can be

ABS MOT RELAY

Turns ABS motor relay ON / OFF

heard

Observe combination me-

ABS WARN LIGHT

Turns ABS warning light ON / OFF

ter

Observe combination me-

BRAKE WRN LIGHT

Turns BRAKE warning light ON / OFF

ter

4.

FREEZE FRAME DATA

(a) The vehicle (sensor) status memorized during ABS operation or at the time of error code detection can

be displayed using the hand-held tester.

(b) Only one record of freeze frame data is stored and the freeze frame data generated during ABS opera-

tion are constantly updated. Also, the number of the ignition switch’s ”ON” after the freeze frame data

is stored can be memorized up to 31 and it can be displayed.

HINT:

If the ignition switch ”ON” operation exceeds 31 times, ”31” appears on the display.

05-301

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

(c)

If the diagnosis code abnormality occurs, the freeze frame data at the occurrence of the abnormality

is stored but the ABS actuation data is deleted.

Hand-held tester display

Measurement Item

Reference Value*

VEHICLE SPD

Vehicle speed

Speed indication of a meter

STOP LIGHT SW

Stop light switch signal

Stop light switch ON: ON, OFF: OFF

Numbers of operations of ignition switch ON after

# IG ON

0 - 31

memorizing freeze frame data

SYSTEM

Operate system

ABS operate: ABS

*: If no conditions are specifically stated for ”Idling”, it means the shift lever is at N or P position, the A/C switch

is OFF and all accessory switches are OFF.

5.

SPEED SENSOR SIGNAL CHECK

HINT:

If the ignition switch is turned from ON to ACC or LOCK during

test mode, DTC will be erased.

(a) In case of not using hand-held tester:

Check the speed sensor signal.

(1)

Turn the ignition switch to ON.

(2)

Using SST, it connects the terminal Ts and CG of

Ts

DLC3.

SST

09843-18040

(3)

Start the engine.

CG

C52361

(4)

Check that the ABS warning light blinks.

HINT:

0.13 sec.

0.13 sec.

If the ABS warning light does not blink, inspect the ABS warning

light circuit and Ts circuit

(See page 05-332 or 05-335).

ON

(5)

Drive the vehicle straight forward at the speed of 45

km/h (28 mph) or over for several seconds and

check that the ABS warning light comes off.

OFF

HINT:

BR3904

The sensor check may not be completed if the wheels spin or

the steering wheels steered during check.

(6)

Stop the vehicle.

(7)

Using SST, it connects the terminal Tc and CG of the

DLC3.

SST

09843-18040

(8)

Read the number of blinks of the ABS warning light.

05-302

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

HINT:

F

See the list of DTC shown on the 05-303.

F

If every sensor is normal, a normal code is output (A cycle

of 0.25 sec. ON and 0.25 sec. OFF is repeated).

F

If 2 or more malfunctions are indicated at the same time,

the lowest numbered code will be displayed.

Malfunction Code (Example Code 72, 76)

7

2

7

6

ON

OFF

1.5 sec.

2.5 sec.

4 sec.

0.5 sec.

0.5 sec.

Repeat

0.5 sec. 0.5 sec.

BR3893

(9)

After performing the check, turn the ignition switch

to OFF, and remove the SST from the DLC3.

SST

09843-18040

(b) In case of using hand-held tester:

Check the speed sensor signal.

(1)

Do step (3) to (6) on the previous page.

(2)

Read the DTC by following the prompts on the tes-

ter screen.

HINT:

Please refer to the hand-held tester operator’s manual for fur-

ther details.

05-312

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

057UF-05

DTC

C0210/33

RIGHT REAR SPEED SENSOR CIRCUIT

DTC

C0215/34

LEFT REAR SPEED SENSOR CIRCUIT

DTC

C1238/38

FOREIGN MATTER IS ATTACHED ON TIP OF

RIGHT REAR SENSOR

DTC

C1239/39

FOREIGN MATTER IS ATTACHED ON TIP OF

LEFT REAR SENSOR

CIRCUIT DESCRIPTION

Refer to DTC C0200/31, C0205/32, C1235/35, C1236/36 on page 05-308.

DTC No.

DTC Detecting Condition

Trouble Area

Detection of any of conditions 1. through 3.:

1. At vehicle speed of 10 km/h (6 mph) or more, pulses are

not input for 15 sec.

C0210/33

F Right rear and left rear speed sensor

2. Momentary interruption of the speed sensor signal oc-

C0215/34

F Each speed sensor circuit

curs at least 7 times in the time between switching the

F Speed sensor rotor

ignition switch ON and switching it OFF.

3. The condition that the speed sensor signal circuit is

open continues for 0.5 sec. or more.

At the vehicle speed of 20 km/h (12 mph) or more, the

C1238/38

F Right rear and left rear speed sensor

condition that noise is included in the speed sensor signal

C1239/39

F Speed sensor rotor

continues for 5 sec. or more.

HINT:

DTC No. C0210/33, C1238/38 is for the right rear speed sensor.

DTC No. C0215/34, C1239/39 is for the left rear speed sensor.

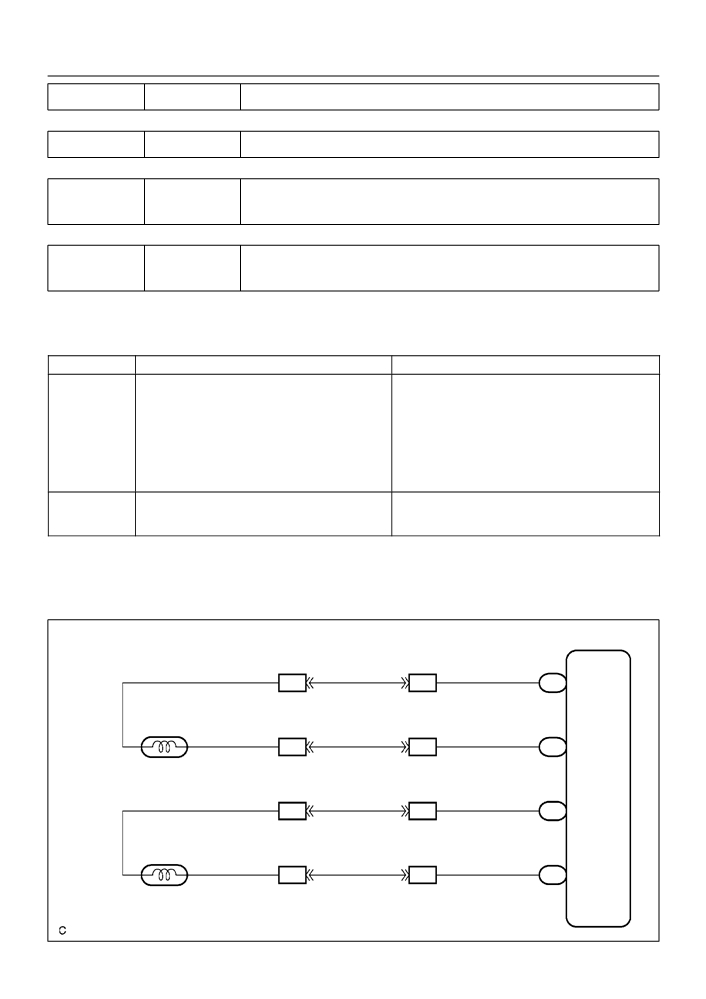

WIRING DIAGRAM

Skid Control ECU

with Actuator

2

2

6

W

Y

Y

BC1

IB1

S1

RL-

A19

ABS Speed Sensor

Rear LH

1

1

7

B

B

B

BC1

IB1

S1

RL+

1

2

2

4

4

W

W

W

BC1

IB1

S1

RR-

A20

ABS Speed Sensor

Rear RH

1

3

5

B

R

R

BC1

IB1

S1

RR+

1

2

F44146

05-313

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

INSPECTION PROCEDURE

HINT:

Start the inspection from step 1 in case of using the hand-held tester and start from step 2 in case of not

using the hand-held tester.

1

READ VALUE OF HAND-HELD TESTER(SKID CONTROL SENSOR)

(a) Check that there is no difference between the speed value output from the speed sensor displayed

by the hand-held tester and the speed value displayed by the speedometer when driving the vehicle.

OK:

There is almost no difference in the displayed speed value.

HINT:

There is tolerance of ± 10 % in the speedometer indication.

OK Go to step 5

NG

2

INSPECT SKID CONTROL SENSOR

(a) Disconnect the skid control sensor connector.

(b) Measure resistance between terminals 1 and 2 of the skid

control sensor connector.

OK:

Resistance: 2.2 k Wor less

(c)

Measure resistance between each of terminals 1 and 2 of

skid control sensor connector and body ground.

OK:

F41836

Resistance: 1 M W or higher

NG REPLACE SKID CONTROL SENSOR

NOTICE:

Check the speed sensor signal last (See page

05-297).

OK

3

CHECK HARNESS AND CONNECTOR(SKID CONTROL SENSOR - SKID

CONTROL ECU)

(a) Check for open and short circuit in harness and connector between each skid control sensor and skid

control ECU (See page 01-30).

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

05-314

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

4

INSPECT SENSOR AND SENSOR ROTOR SERRATIONS

(REFERENCE) INSPECTION USING OSCILLOSCOPE

Normal Signal Waveform

(a) Connect the oscilloscope to the terminals RR+ - RR- and

RL+ - RL- of the skid control ECU.

(b) Drive the vehicle at about 30 km/h (19 mph), and check

GND

the signal waveform.

HINT:

F

As the vehicle speed (wheel revolution speed) increases,

a cycle of the waveform becomes shorter and the fluctua-

2 m/s / Division

1 V / Division

W04200

tion in the output voltage becomes greater.

F

When noise is identified in the waveform on the oscillo-

scope, error signals are generated due to the speed sen-

sor rotor’s scratches, looseness or foreign matter depos-

ited on it.

OK CHECK AND REPLACE BRAKE ACTUATOR

ASSY

NG

5

INSPECT SENSOR INSTALLATION

(a) Check the sensor installation.

OK:

There is no clearance between the sensor and rear

axle carrier.

OK

NG

F10178

NG REPLACE SKID CONTROL SENSOR

NOTICE:

Check the speed sensor signal last (See page

05-297).

OK

6

INSPECT SKID CONTROL SENSOR TIP

(a) Remove the skid control sensor (See page 32-46).

(b) Check the sensor tip.

OK:

No scratches or foreign objects on the sensor tip.

NG CLEAN OR REPAIR SKID CONTORL SENSOR

NOTICE:

Check the speed sensor signal last (See page

05-297).

OK

05-315

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

7

INSPECT SENSOR ROTOR

(a) Check the sensor rotor serrations.

OK:

No scratches, missing teeth or foreign objects.

W04846

NG REPLACE REAR AXLE HUB & BEARING ASSY

RH

NG REPLACE REAR AXLE HUB & BEARING ASSY

LH

NOTICE:

Check the speed sensor signal last (See page

05-297).

OK

CHECK AND REPLACE BRAKE ACTUATOR ASSY (See page

05-306)

NOTICE:

Do not reuse skid control sensor.

05-307

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

057UD-04

PROBLEM SYMPTOMS TABLE

If a normal code is displayed during the DTC check but the problem still occurs, check the circuits for each

problem symptom in the order given in the table below and proceed to the relevant troubleshooting page.

NOTICE:

When replacing Skid Control ECU, sensor or etc., turn the ignition switch to OFF.

Symptom

Suspect Area

See page

When the followings 1. to4. are all normal and the problem

is still occurring, replace the skid control ECU.

1. Check the DTC reconfirming that the normal code is

05-297

output.

ABS does not operate

2. IG power source circuit

05-324

3. Speed sensor circuit

05-308

05-312

4. Check the brake actuator with a hand-held tester.

32-40

If abnormal, check the hydraulic circuit for leakage.

When the following 1. to 4. are all normal and the problem

is still occurring, replace the skid control ECU.

1. Check the DTC reconfirming that the normal code is

05-297

output.

ABS does not operate efficiently

2. Speed sensor circuit

05-308

05-312

3. Stop light switch circuit

05-327

4. Check the brake actuator with a hand-held tester.

32-40

If abnormal, check the hydraulic circuit for leakage.

1. ABS warning light circuit

05-332

ABS warning light abnormality

05-335

2. Skid control ECU

-

When the following 1. and 2. are all normal and the problem

is still occurring, replace the skid control ECU.

DTC check cannot be done

1. ABS warning light circuit

05-332

05-335

2. Tc terminal circuit

05-341

1. Ts terminal circuit

05-343

Speed sensor signal check cannot be done

2. Skid control ECU

-