Toyota Corolla (2004+). Manual - part 37

51-14

POWER STEERING

- VANE PUMP ASSY

33. INSTALL POWER STEERING SUCTION PORT UNION

(a) Coat a new O-ring with power steering fluid, and install it to the power steering suction port union.

(b) Install the power steering suction port union with the bolt.

Torque: 12 N m (120 kgf cm, 9 ft lbf)

34. INSTALL VANE PUMP ASSY

(a) Install the vane pump assy with the 2 bolts and nuts.

Torque: 37 N m (380 kgf cm, 27 ft lbf)

(b) Connect the oil pressure switch connector.

NOTICE:

Be careful that the oil does not adhere to the connector.

C80321

35. INSTALL VANE PUMP BRACKET REAR

(a) Install the vane pimp bracket rear with the bolt.

Torque: 37 N m (380 kgf cm, 27 ft lbf)

36. CONNECT PRESSURE FEED TUBE ASSY

SST

(a) Using SST, connect the pressure feed tube assy.

SST

09023-38400

Fulcrum

Torque: 41 N m (420 kgf cm, 30 ft lbf)

Length

HINT:

F

Use a torque wrench with a fulcrum length of 345 mm

(13.58 in.).

F

This torque value is effective when SST is parallel to a

F13579

torque wrench.

(b) Connect the pressure feed tube clamp with the bolt.

Torque: 7.8 N m (80 kgf cm, 69 ft lbf)

37. CONNECT OIL RESERVOIR TO PUMP HOSE NO.1

(a) Connect the oil reservoir to pump hose No.1 with the clip.

38. INSTALL FAN AND GENERATOR V BELT

39. INSTALL FRONT WHEEL RH

Torque: 103 N m (1,050 kgf cm, 76 ft lbf)

40. ADD POWER STEERING FLUID

41. BLEED POWER STEERING FLUID(See page 51-3)

42. INSPECT FLUID LEAK

43. INSTALL ENGINE UNDER COVER RH

05-335

DIAGNOSTICS

-

ABS WITH EBD SYSTEM (April, 2003)

057UN-04

ABS WARNING LIGHT CIRCUIT (DOES NOT LIGHT UP)

CIRCUIT DESCRIPTION

If the ECU detect trouble, it will prohibit ABS control, turn on ABS warning light, and store the DTC.

Connect terminals Tc and CG of the DLC3 to make the ABS warning light blink and output the DTC.

05-336

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

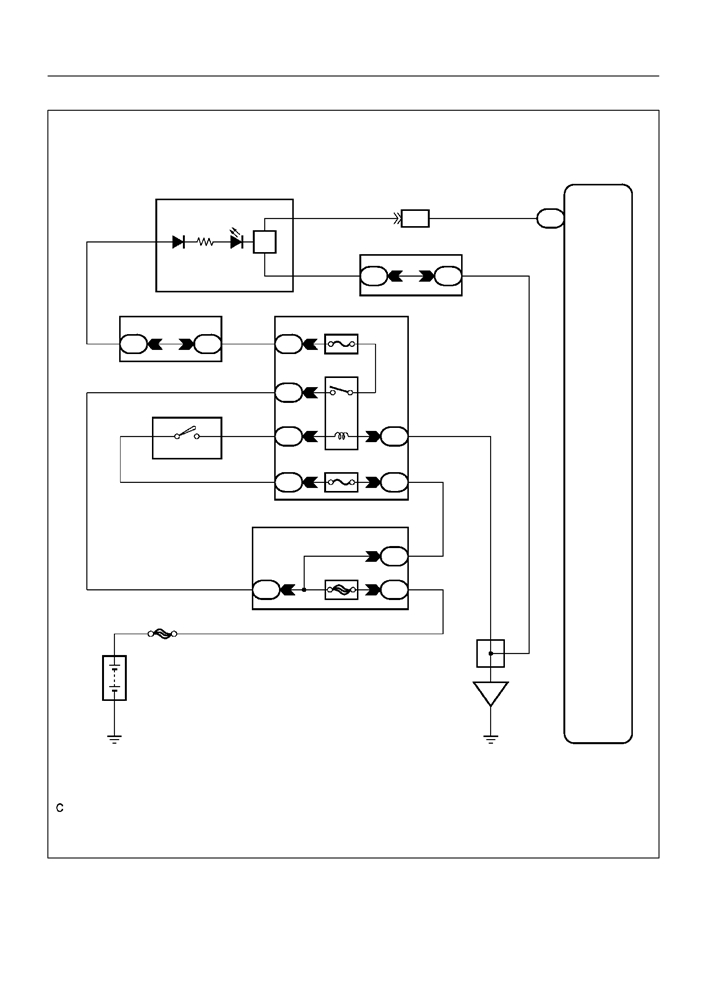

WIRING DIAGRAM

Skid Control ECU

C9

with Actuator

Combination Meter

5

30

W-R

W-R

IA6

S1

WA

37

R-W

Center J/B

4

ABS

18

21

W-B

W-B

4B

4B

2

RH J/B

Instrument Panel J/B

16

22

2

GAUGE

R-W

3B

3B

IG

IG1 Relay

1

W

IA

I10 Ignition SW

5

3

2

4

W

B-Y

W-B

IF

IF

1

2

AM1

IG1

1

2

12

AM1

1

W

W

IF

IB

Engine Room J/B

1

W

1C

1

ALT

1

W

1D

1A

2

1

FL MAIN

B

A

J6

J/C

A

Battery

IE

F42890

05-337

DIAGNOSTICS

-

ABS WITH EBD SYSTEM (April, 2003)

INSPECTION PROCEDURE

HINT:

Start the inspection from step 1 in case of using the hand-held tester and start from step 2 in case of not

using the hand-held tester.

1

PERFORM ACTIVE TEST BY HAND-HELD TESTER(ABS WARNING LIGHT)

(a) Check that ”ON” and ”OFF” of the ABS warning light can be shown on the combination meter by the

hand-held tester.

OK CHECK AND REPLACE BRAKE ACTUATOR

ASSY (See page 05-306)

NG

2

INSPECT COMBINATION METER ASSY(ABS WARNING LIGHT)

(a) Disconnect the connector from the skid control ECU.

(b) Turn the ignition switch to ON.

(c)

Check the ABS warning light.

OK:

ABS warning light goes ON

NG REPAIR OR REPLACE COMBINATION METER

ASSY

OK

3

CHECK HARNESS AND CONNECTOR(WA CIRCUIT)

(a) Check for short circuit in harness and connector of the between terminal WA of skid control ECU and

combination meter (See page 01-30).

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK AND REPLACE BRAKE ACTUATOR ASSY (See page

05-306)

05-332

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

057UM-04

DTC

AlwaysON

MALFUNCTION IN ABS ECU

CIRCUIT DESCRIPTION

DTC No.

DTC Detecting Condition

Trouble Area

F Battery

Either of the following 1. or 2. is detected:

F Charging system

Always ON

1. The ECU connectors are OFF from the ECU.

F Power source circuit

2. There is a malfunction in the ECU internal circuit.

F Skid control ECU

HINT:

There is a case that hand-held tester cannot be used when ECU is abnormal.

WIRING DIAGRAM

Skid Control ECU

Instrument Panel J/B

with Actuator

IG1 Relay

1

ECU-IG

13

3

W

B-W

IA

IC

S1

IG1

I10

5

3

Ignition SW

2

4

B-Y

W-B

1

IF

IF

W-B

1

2

S1

GND1

1

2

AM1

IG1

12

AM1

1

W

IF

IB

23

W-B

S1

GND2

Engine Room J/B

1

W

1D

1

ALT

1

FL MAIN

W-B

B

W

1A

1C

1

2

A

J6

J/C

Battery

IE

EA

F42888

05-333

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

INSPECTION PROCEDURE

1

RECONFIRM DTC

(a) Check the DTC (See page 05-297).

YES REPAIR CIRCUIT INDICATED BY OUTPUT

CODE

NO

2

INSPECT SKID CONTROL ECU CONNECTOR SECURELY CONNECTED

NO CONNECT CONNECTOR TO ECU

YES

3

INSPECT SKID CONTROL ECU CONNECTOR(IG1 TERMINAL VOLTAGE)

IN CASE OF USING HAND-HELD TESTER:

(a) Check the voltage condition output from the ECU displayed on the hand-held tester.

OK:

”Normal” is displayed.

IN CASE OF NOT USING HAND-HELD TESTER:

IG1 (+)

GND1 (-)

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to ON.

(c)

Measure voltage between terminals IG1 (3) and GND (1,

23) of skid control ECU harness side connector.

OK:

oltage: 10 - 14 V

GND2(-)

C58919

OK Go to step 5

NG

05-334

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

4

INSPECT SKID CONTROL ECU CONNECTOR(GND TERMINAL CONTINUITY)

(a) Measure resistance between terminal GND (S1-2, 24) of

GND1

skid control ECU harness side connector and body

ground.

Resistance: 1

W or less

GND2

C58919

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK AND REPAIR HARNESS AND CONNECTOR

5

GO TO COMBINATION METER SYSTEM(ABS WARNING LIGHT)

(a) Disconnect the skid control ECU connector.

GND1

(b) Using service wire, connect terminals WA (30) and GND

(1, 23) of skid control ECU harness side connector.

(c)

Turn the ignition switch to ON.

OK:

ABS warning light goes off.

GND2

WA

C58919

NG REPAIR OR REPLACE COMBINATION METER

ASSEMBLY

OK

CHECK AND REPLACE BRAKE ACTUATOR ASSY(See page

05-306)

05-338

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

057UO-04

BRAKE WARNING LIGHT CIRCUIT

CIRCUIT DESCRIPTION

If the ECU detects trouble, it lights the brake warning light at the same time of prohibiting ABS control. At

this time, the ECU records a DTC in memory.

Connect terminals Tc and CG of the DLC3 to make the brake warning light blink and output the DTC.

05-339

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

WIRING DIAGRAM

Skid Control ECU

C9

with Actuator

Combination Meter

5

30

W-R

W-R

IA6

S1

WA

37

R-W

Center J/B

4

ABS

18

21

W-B

W-B

4B

4B

2

RH J/B

Instrument Panel J/B

16

22

2

GAUGE

R-W

3B

3B

IG

IG1 Relay

1

W

IA

I10 Ignition SW

5

3

2

4

W

B-Y

W-B

IF

IF

1

2

AM1

IG1

1

2

12

AM1

1

W

W

IF

IB

Engine Room J/B

1

W

1C

1

ALT

1

W

1D

1A

2

1

FL MAIN

B

A

J6

J/C

A

Battery

IE

F42890

05-340

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

INSPECTION PROCEDURE

1

INSPECT PARKING BRAKE SWITCH CIRCUIT

(a) Check for open and short circuit in parking brake switch circuit (See page 01-30).

NG REPAIR OR REPLACE PARKING BRAKE

SWITCH CIRCUIT

OK

2

INSPECT BRAKE FLUID LEVEL WARNING SWITCH CIRCUIT

(a) Check the brake fluid level in reservoir.

(b) Check for open and shot circuit in brake fluid level warning switch circuit (See page

01-30).

NG REPAIR OR REPLACE BRAKE FLUID LEVEL

WARNING SWITCH CIRCUIT

OK

3

CHECK DTC ONCE MORE

(a) Check for open and short circuit in harness and connector between vacuum warning switch and skid

control ECU (See page 05-297).

NG REPAIR CIRCUIT INDICATED BY OUTPUT

CODE

OK

4

INSPECT COMBINATION METER ASSEMBLY(BRAKE WARNING LIGHT CIRCUIT)

(a) Check for open and short circuit in combination meter (See page 01-30).

NG REPAIR OR REPLACE COMBINATION METER

ASSEMBLY

OK

5

CHECK HARNESS AND CONNECTOR(BRAKE ACTUATOR - COMBINATION

METER)

(a) Check for open and short circuit in harness and connector between brake actuator and combination

meter (See page 01-30).

NG REPAIR OR REPLACE HARNESS OR

CONNECTOR

OK

CHECK AND REPLACE BRAKE ACTUATOR ASSY

05-324

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

057UJ-04

DTC

C1241/41

LOW BATTERY POSITIVE VOLTAGE OR

ABNORMALLY HIGH BATTERY POSITIVE

VOLTAGE

CIRCUIT DESCRIPTION

This is the power source of the ECU, hence the actuators.

DTC No.

DTC Detecting Condition

Trouble Area

Detection of any of conditions 1. through 3. :

1. With vehicle speed at 3 km/h or more, IG1 terminal volt-

age is 10V or below for 10 sec. or longer.

F Battery

2. With IG1 terminal voltage at 10V or below, solenoid relay

C1241/41

F Charging system

open, pump motor relay open, solenoid fault detecting

F Power source circuit

condition are established

3. Voltage of ECU terminal IG1 remains at more than 17V

continues for 1.2 sec. or more.

WIRING DIAGRAM

Skid Control ECU

Instrument Panel J/B

with Actuator

IG1 Relay

1

ECU-IG

13

3

W

B-W

IA

IC

S1

IG1

I10

5

3

Ignition SW

2

4

1

B-Y

W-B

IF

IF

W-B

1

2

S1

GND1

1

2

AM1

IG1

12

AM1

1

W

IF

IB

23

W-B

S1

GND2

Engine Room J/B

1

W

1D

1

ALT

1

FL MAIN

W-B

B

W

1A

1C

1

2

A

J6

J/C

Battery

IE

EA

F42888

05-325

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

INSPECTION PROCEDURE

1

INSPECT FUSE(ECU-IG FUSE)

(a) Remove ECU-IG fuse from the instrument panel J/B.

(b) Check continuity of ECU-IG fuse.

Instrument Panelk J/B

OK:

Continuity

ECU-IG

NG INSPECT FOR SHORT CIRCUIT IN ALL

HARNESS AND COMPONENTS CONNECTED

I32648

TO ECU-IG FUSE

OK

2

INSPECT BATTERY

OK:

Voltage: 10 - 14 V

NG INSPECT CHARGING SYSTEM

OK

05-326

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

3

INSPECT SKID CONTROL ECU CONNECTOR(IG1 TERMINAL VOLTAGE)

IN CASE OF USING HAND-HELD TESTER:

(a) Check the voltage condition output from the ECU displayed on the hand-held tester.

OK:

”Normal” is displayed.

IN CASE OF NOT USING HAND-HELD TESTER:

IG1 (+)

GND1 (-)

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to ON.

(c)

Measure voltage between terminals IG1 (3) and GND (1,

23) of skid control ECU harness side connector.

OK:

oltage: 10 - 14 V

GND2(-)

C58919

OK CHECK AND REPLACE BRAKE ACTUATOR

ASSY

NG

4

INSPECT SKID CONTROL ECU CONNECTOR(GND TERMINAL CONTINUITY)

(a) Measure resistance between terminal GND (1, 23) of skid

GND1

control ECU harness side connector and body ground.

OK:

Resistance: 1

W or less

NG REPAIR OR REPLACE HARNESS OR

GND2

C58919

CONNECTOR

OK

CHECK AND REPLACE BRAKE ACTUATOR ASSY (See page

05-306)

05-327

DIAGNOSTICS

-

ABS WITH EBD SYSTEM (April, 2003)

057UK-04

DTC

C1249/49

OPEN CIRCUIT IN STOP LIGHT SWITCH

CIRCUIT

CIRCUIT DESCRIPTION

DTC No.

DTC Detecting Condition

Trouble Area

With IG1 terminal voltage at 10V - 16V, ABS not controlling

F Stop light switch

C1249/49

stop light switch circuit is open for 1.0 sec. or longer.

F Stop light switch circuit

05-328

DIAGNOSTICS

- ABS WITH EBD SYSTEM (April, 2003)

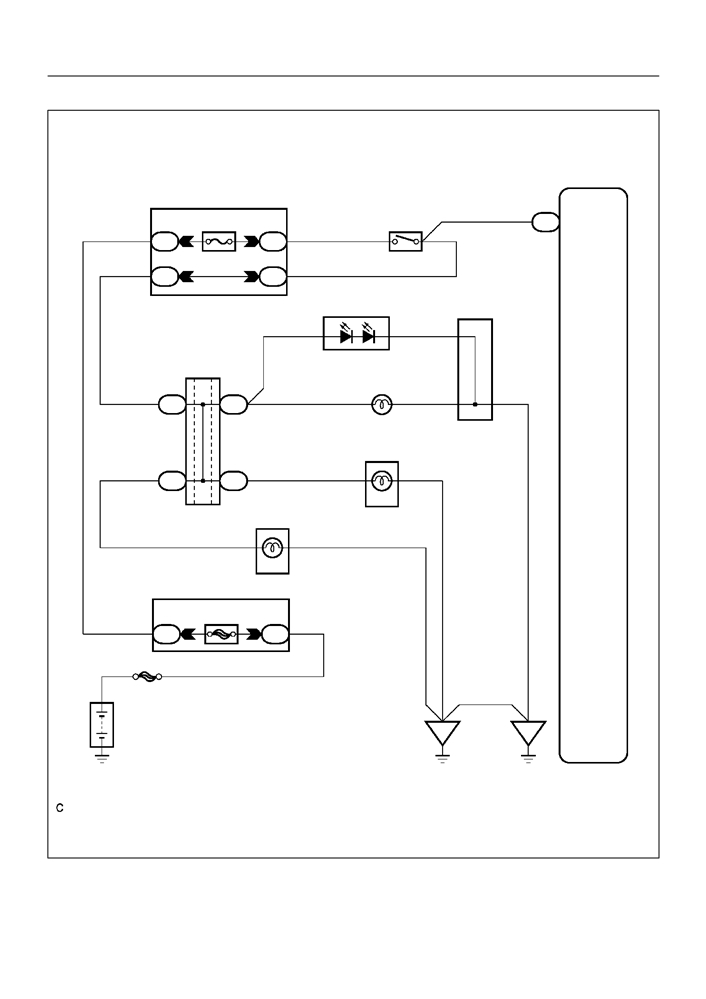

WIRING DIAGRAM

Skid Control ECU

with Actuator

S9

Instrument Panel J/B

16

Stop Control SW

G-W

1

STOP

14

S1

STP

W

R-W

IB

IC

2

1

7

5

G-W

G-W

ID

IC

H9

J8

High Mounted Stop Light

J/C

G-W

(*1)

W-B (*1)

1

2

A

H9

J/C

High Mounted Stop Light

C

B

G-W

G-W

(*2)

W-B

(*2)

W-B

J9

J8

1

2

A

A

R11

Rear Combination Light RH

C

B

G-W

G-W

W-B

J9

J8

2

4

Stop

R9

Rear Combination Light LH

G-W

W-B

2

4

Stop

Engine Room J/B

1

ALT

1

W

1C

1A

2

1

FL MAIN

B

W-B

Battery

BI

BH

*1: LED Type

*2: Bulb Type

F42889