Toyota Corolla (2004+). Manual - part 29

41-43

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

54. INSPECT TRANSMISSION HUB SLEEVE NO.3

(a) Check the sliding condition between the transmission hub

sleeve No. 3 and transmission clutch hub No.3.

(b) Check that spline gear’s of the transmission hub sleeve

No.3 is not worn down.

C67978

(c)

Using a vernier calipers, inspect the transmission hub

sleeve No.3 and gear shift fork No.3 as shown in the il-

A

lustration.

Standard clearance:

0.3 - 0.5 mm (0.012 - 0.020 in.)

If the clearance is out of specification, replace the transmission

hub sleeve No.3 and gear shift fork No.3.

B

Clearance= (A - B)

C80375

55. INSPECT 5TH GEAR

(a) Using a caliper gauge, inspect 5th gear as shown in the

illustration.

5th gear inner diameter:

Standard inner diameter: mm (in.)

Maximum inner diameter: mm (in.)

29.915 - 29.931 (1.1778 - 1.1783)

29.931

(1.1783)

If the inner diameter exceeds the maximum, replace the 5th

gear.

C67975

41-44

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

56. INSPECT REVERSE IDLER GEAR SUB-ASSY

(a) Using a caliper gauge, inspect the reverse idler gear sub-

assy as shown in the illustration.

Reverse idler gear sub-assy inner diameter:

Standard inner diameter: mm (in.)

Maximum inner diameter: mm (in.)

18.040 - 18.058 (0.7102 - 0.7109)

18.058

(0.7109)

If the inner diameter exceeds the maximum, replace the re-

verse idler gear sub-assy.

(b) Using a micrometer, inspect the reverse idler gear shaft

as shown in the illustration.

Reverse idler gear shaft outer diameter:

Standard inner diameter: mm (in.)

Minimum outer diameter: mm (in.)

17.966 - 17.984 (0.7073 - 0.7080)

17.966

(0.7073)

If the outer diameter is below the minimum, replace the reverse

idler gear shaft.

C67846

Case

57. INSTALL OUTPUT SHAFT (MTM) COVER

Cover

(a) Coat the output shaft (MTM) cover with MP grease, install

it to the transaxle case.

NOTICE:

Install the output shaft (MTM) cover projection into the case

side hollow.

C95191

58. INSTALL OUTPUT SHAFT FRONT BEARING

(a) Coat a new output shaft front bearing with gear oil, using

SST

SST and a press, install it to the transaxle case.

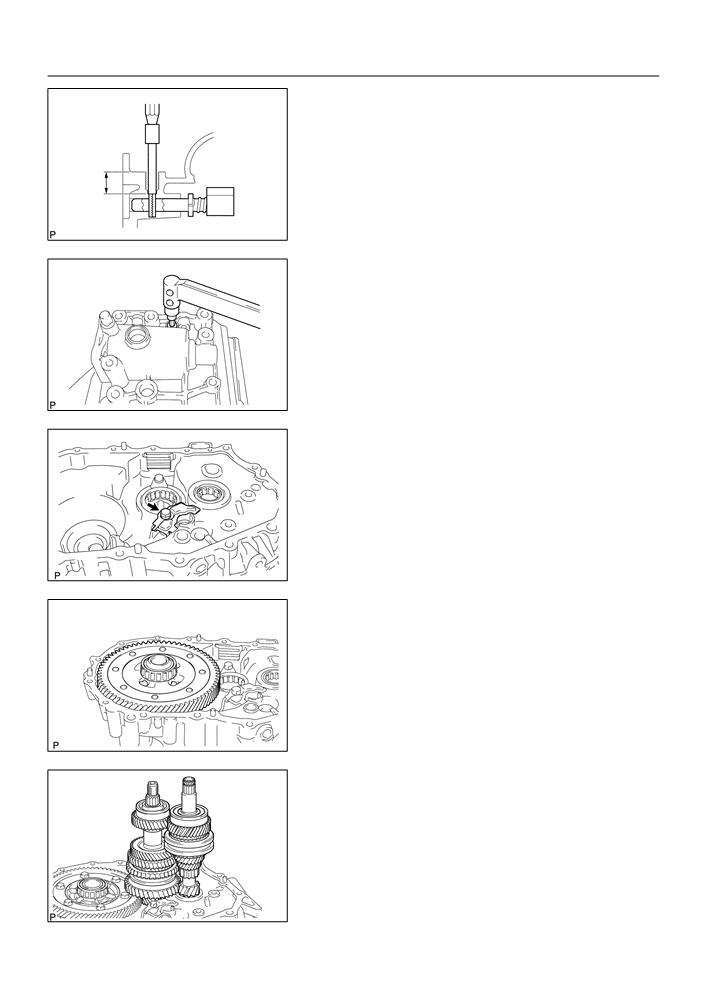

SST

09950-60010 (09951-00550), 09950-70010

(09951-07150)

NOTICE:

F

Be sure to install a new bearing in the correct direc-

tion, as shown in the illustration.

C80376

F

When replacing the output shaft front bearing, re-

place the output shaft front bearing inner race along

with it.

41-45

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

59. INSTALL FRONT TRANSAXLE CASE OIL SEAL

(a) Using SST and a hammer, install a new front transaxle

case oil seal to the transaxle case.

SST

SST

09950-60010 (09951-00370), 09950-70010

(09951-07150)

Drive in depth: 15.6 - 16.0 mm (0.6142 - 0.6299 in.)

(b) Coat the lip of the front transaxle case oil seal with MP

grease.

C81790

60. INSTALL INPUT SHAFT FRONT BEARING

SST

(a) Coat a new input shaft front bearing with MP grease, us-

ing SST and a press, install it to the transaxle case.

SST

09950-60010 (09951-00420), 09950-70010

(09951-07150)

Drive in depth: 0 - 0.3 mm (0 - 0.012 in.)

C95192

61. INSTALL FR DIFFERENTIAL CASE FRONT TAPERED

ROLLER BEARING

SST

(a) Using SST and a press, install a new FR differential case

front tapered roller bearing (inner race) to the front differ-

ential case.

SST

09350-32014 (09351-32120), 09950-60010

(09951-00530)

C95110

(b) Using SST and a press, install a new FR differential case

front tapered roller bearing (outer race) with shim to the

transaxle case.

SST

SST

09950-60020 (09951-00680), 09950-70010

(09951-07150)

C80379

62. INSTALL FR DIFFERENTIAL CASE REAR TAPERED

SST

ROLLER BEARING

(a) Using SST and a press, install a new FR differential case

rear tapered roller bearing (inner race) to the front differ-

ential case.

SST

09350-32014 (09351-32120), 09950-60010

(09951-00530)

C95111

41-46

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

(b) Using SST and a press, install a new FR differential case

rear tapered roller bearing (outer race) with shim to the

SST

manual transmission case.

SST

09309-36010, 09950-60020 (09951-00710),

09950-70010 (09951-07150)

HINT:

Use a shim of the same thickness with the removed one.

C81792

63. ADJUST DIFFERENTIAL SIDE BEARING RRELOAD

(a) Coat the differential case assy with gear oil, install it to the

transaxle case.

(b) Install the manual transmission case with 16 bolts.

Torque: 29.4 N m (300 kgf cm, 22 ft lbf)

C67656

(c)

Using SST and a torque wrench, turn the differential case

SST

assy to the right and left 2 or 3 times to allow the bearings

to settle.

SST

09564-32011

C81793

41-47

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

(d) Using SST and a torque wrench, measure the preload.

SST

SST

09564-32011

Preload (at starting):

New bearing:

0.78 - 1.57 Nm (8 - 16 kgf cm, 6.9 - 13.9 in. lbf)

If the preload is out of specification, select another shim.

Shim thickness:

Mark

Thickness: mm (in.)

Mark

Thickness: mm (in.)

C81793

AA

2.10

(0.0827)

LL

2.60

(0.1024)

BB

2.15

(0.0846)

MM

2.65

(0.1043)

CC

2.20

(0.0866)

NN

2.70

(0.1063)

DD

2.25

(0.0886)

PP

2.75

(0.1083)

EE

2.30

(0.0906)

QQ

2.80

(0.1102)

FF

2.35

(0.0925)

RR

2.85

(0.1122)

GG

2.40

(0.0945)

SS

2.90

(0.1142)

HH

2.45

(0.0965)

TT

2.95

(0.1161)

JJ

2.50

(0.0984)

UU

3.00

(0.1181)

KK

2.55

(0.1004)

-

-

HINT:

The preload will change by about 0.3 - 0.4 Nm (3 - 4 kgfcm,

2.6 - 3.5 in.lbf) corresponding to a change of 0.05 mm (0.0020

in.) in shim thickness.

(e) Remove the 16 bolts and manual transmission case from

the transaxle case.

(f)

Remove the differential case assy from the transaxle

case.

64. INSTALL TRANSMISSION CASE OIL SEAL

(a) Using SST and a hammer, install a new transmission case

SST

oil seal to the manual transmission case.

SST

09316-60011 (09316-00011)

Drive in depth: 9.9

0.3 mm (0.390

0.012 in.)

(b) Coat the lip of the transmission case oil seal with MP

grease.

C80381

65. INSTALL TRANSAXLE CASE OIL SEAL

(a) Using SST and a hammer, install a new transaxle case oil

SST

seal in the transaxle case.

SST

09710-20011 (09710-06071), 09950-70010

(09951-07150)

Drive in depth: 1.9

0.3 mm (0.075

0.012 in.)

(b) Coat the lip of the transaxle case oil seal with MP grease.

C80382

41-48

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

66. INSTALL TRANSMISSION MAGNET

(a) Clean the transmission magnet, install it to the transaxle

case.

C67659

67. INSTALL BEARING LOCK PLATE

(a) Install the bearing lock plate with the bolt.

Torque: 11.3 N m (115 kgf cm, 8 ft lbf)

C67658

68. INSTALL OIL RECEIVER PIPE NO.1 (MTM)

(a) Install the oil receiver pipe No.1 (MTM) with bolt to the

manual transmission case.

Torque: 17.2 N m (175 kgf cm, 13 ft lbf)

NOTICE:

F

Prevent the oil receiver pipe No.1 (MTM) from being

deformed.

F

Install the oil receiver pipe No.1 (MTM) while placing

C68380

it against the manual transmission case, as

shown in

the illustration.

69. INSTALL OIL RECEIVER PIPE NO.2 (MTM)

(a) Install the oil receiver pipe No.2 (MTM) with bolt to the

manual transmission case.

Torque: 17.2 N m (175 kgf cm, 13 ft lbf)

NOTICE:

F

Prevent the oil receiver pipe No.2 (MTM) from being

deformed.

F

Install the oil receiver pipe No.2 (MTM) while placing

C95781

it against the manual transmission case, as

shown in

the illustration.

70. INSTALL REVERSE RESTRICT PIN ASSY

(a) Install the reverse restrict pin assy to the manual trans-

mission case.

NOTICE:

Do not set the reverse restrict pin assy in incorrect orienta-

tion.

C80383

41-49

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

(b) Using a pin punch (f 5 mm) and hammer, install the

slotted pin to the reverse restrict pin assy.

Drive in depth (A):

15.5 - 16.5 mm (0.6102 - 0.6496 in.)

(c)

Apply sealant to the reverse restrict pin plug.

Sealant:

A

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

C80384

(d) Using a hexagon wrench and a torque wrench, install the

reverse restrict pin plug to the manual transmission case.

Torque: 12.7 N m (130 kgf cm, 9 ft lbf)

C80385

71. INSTALL MANUAL TRANSAXLE CASE RECEIVER

(a) Install the manual transaxle case receiver with the bolt to

the transaxle case.

Torque: 11.3 N m (115 kgf cm, 8 ft lbf)

C67657

72. INSTALL DIFFERENTIAL CASE ASSY

(a) Coat the differential case tapered roller bearing with gear

oil, install the differential case assy to the transaxle case.

C67656

73. INSTALL INPUT SHAFT ASSY

(a) Coat the sliding and rotating surface of the input and out

put shafts with gear oil, install them to the transaxle case.

C80370

41-50

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

74. INSTALL REVERSE IDLER GEAR SUB-ASSY

(a) Coat the reverse idler gear sub-assy, thrust washer and

reverse idler gear shaft with gear oil, install them as

shown in the illustration.

HINT:

Align the mark on the reverse idler gear shaft with the bolt hole

shown in the illustration.

Align Alignment Mark

C80386

75. INSTALL GEAR SHIFT FORK SHAFT SUB-ASSY NO.1

Gear Shift

Fork No.2

(a) Coat the gear shift fork No.1 and gear shift fork No.2 with

gear oil, install them.

Gear Shift

Fork No.1

C80387

(b) Coat the gear shift fork shaft sub-assy No.1 with gear oil,

Gear Shift

install it.

Fork Shaft

(c)

Apply sealant to the shift fork lock bolt.

No.1

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

(d) Install the gear shift fork lock bolt.

Torque: 15.7 N m (160 kgf cm, 12 ft lbf)

C80388

(e) Using a brass bar and a hammer, install the shaft snap

ring to the gear shift fork shaft No.1.

C80389

76. INSTALL GEAR SHIFT FORK SHAFT NO.3

(a) Coat the 2 balls with MP grease, install them to the re-

verse shift fork.

(b) Install the reverse shift fork to the gear shift fork shaft

No.3.

C80450

41-51

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

(c)

Using a brass bar and a hammer, install the 2 shift fork

shaft snap rings to the gear shift fork shaft No.3.

C80391

(d) Coat the gear shift fork shaft No.3 with gear oil, install it.

C80392

77. INSTALL GEAR SHIFT FORK SHAFT NO.2

(a) Coat the gear shift head No.1 and gear shift fork shaft

No.2 with gear oil, install them.

C80362

NOTICE:

To avoid the interference of the 2 shift fork balls, lift up the

gear shift fork shaft NO.3 at the position shown in the il-

lustration.

C95193

(b) Coat the 2 shift lock bolts with sealant, install then to the

gear shift fork No.2 and gear shift head No.1.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

Torque: 15.7 N m (160 kgf cm, 12 ft lbf)

C80361

41-52

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

78. INSTALL REVERSE SHIFT ARM BRACKET ASSY

(a) Install the reverse shift arm bracket assy with 2 bolts to the

transaxle case.

Torque: 17.2 N m (175 kgf cm, 13 ft lbf)

C80360

79. INSTALL MANUAL TRANSMISSION CASE

FIPG

(a) Apply FIPG to the manual transmission case, as shown

in the illustration.

FIPG:

Part No. 08826-00090, THREE BOND 1281 or equiva-

lent

NOTICE:

Parts must be assembled within 10 minutes of application.

C82142

Otherwise, the packing (FIPG) material must be removed

and reapplied.

(b) Coat the 13 bolts with sealant, install them to the manual

transmission case.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

Torque: 29.4 N m (300 kgf cm, 22 ft lbf)

C80358

(c)

Coat the 3 bolts with sealant, install them to the transaxle

case.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

Torque: 29.4 N m (300 kgf cm, 22 ft lbf)

C80357

80. INSTALL REVERSE IDLER GEAR SHAFT BOLT

(a) Coat the reverse idler gear shaft bolt with sealant, install

it with a new gasket.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

Torque: 29.4 N m (300 kgf cm, 22 ft lbf)

C67639

41-53

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

81. INSTALL LOCK BALL ASSY NO.1

(a) Coat the lock ball assy No.1 with sealant, install it with us-

ing a hexagon wrench.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

Torque: 39.2 N m (400 kgf cm, 29 ft lbf)

C80356

82. INSTALL SHIFT DETENT BALL

(a) Install the 2 shift detent balls, 2 springs with 2 seats to the

manual transmission case.

C68417

(b) Coat the 2 shift detent ball plugs with sealant, install them

with using a hexagon wrench.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

Torque: 24.5 N m (250 kgf cm, 18 ft lbf)

C67634

(c)

Install the shift detent ball, spring and seat to the transaxle

case.

C80393

(d) Coat the shift detent ball plug with sealant, install it with

using a hexagon wrench.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

Torque: 24.5 N m (250 kgf cm, 18 ft lbf)

C80354

41-54

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

83. INSTALL INPUT SHAFT REAR BEARING HOLE SNAP

RING

(a) Using a snap ring expander, install the input shaft rear

bearing hole snap ring to the input shaft.

C80352

84. INSTALL OUTPUT SHAFT REAR BEARING HOLE

SNAP RING

(a) Using a snap ring expander, install the output shaft rear

bearing hole snap ring to the output shaft.

C80351

85. INSTALL SHIFT FORK SHAFT SHAFT SNAP RING

(a) Using a brass bar and a hammer, install the shift fork shaft

shaft snap ring to the shift fork shaft No.2.

C80394

86. INSTALL BEARING RETAINER REAR (MTM)

(a) Coat the 5 bolts with sealant, install them and bearing re-

tainer rear (MTM) to the manual transmission case.

Torque: 27.4 N m (279 kgf cm, 20 ft lbf)

C80350

87. INSTALL 5TH DRIVEN GEAR

(a) Using SST, install the 5th driven gear to the output shaft.

SST

09309-12020

SST

SST

C95786

41-55

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

88. INSTALL 5TH GEAR NEEDLE ROLLER BEARING

(a) Coat the 5th gear needle roller bearing and 5th gear bear-

ing spacer with gear oil, install them to the input shaft.

C80348

89. INSTALL 5TH GEAR

(a) Coat the 5th gear with gear oil, install it to the input shaft.

C80396

90. INSTALL SYNCHRONIZER RING NO.3

(a) Coat the synchronizer ring No.3 with gear oil, install it to

the 5th gear.

Key position

C80397

91. INSTALL TRANSMISSION CLUTCH HUB NO.3

(a) Install the 3 synchromesh shifting keys and 2 synchro-

mesh shifting key springs to the transmission clutch hub

No.3.

HINT:

Do not set both openings of the shifting key springs in the same

position.

Engine

Side

C80398

41-56

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

(b) Using SST and a hammer, install the transmission clutch

hub No.3 to the input shaft.

SST

09636-20010

HINT:

SST

F

Before driving in the No.3 clutch hub assy, place the suit-

able sized wooden block on the rear side of the input

shaft, as shown in the illustration.

Key position

F

When driving it in, fix the input shaft firmly so that it is not

pushed downward. Otherwise the input shaft rear bearing

is over loaded, it might be damaged.

Wooden Block

C80399

(c)

Select a snap ring from the table below that will make the

thrust clearance of the transmission clutch hub No.3 be-

low 0.1 mm (0.0039 in.).

Snap ring thickness:

Mark

Thickness: mm (in.)

Mark

Thickness: mm (in.)

A

2.25

(0.0886)

E

2.49

(0.0980)

B

2.31

(0.0909)

F

2.55

(0.1004)

C

2.37

(0.0933)

G

2.61

(0.1028)

D

2.43

(0.0957)

-

-

C80400

(d) Using a brass bar and a hammer, install the snap ring to

the input shaft.

92. INSPECT 5TH GEAR THRUST CLEARANCE

(a) Using a dial indicator, measure the 5th gear thrust clear-

ance.

5th gear thrust clearance:

Standard clearance: mm (in.)

Maximum clearance: mm (in.)

0.10 - 0.57 (0.0039 - 0.0224)

0.57

(0.0224)

C80344

41-57

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

93. INSPECT 5TH GEAR RADIAL CLEARANCE

(a) Using a dial indicator, measure the 5th gear radial clear-

ance.

5th gear radial clearance:

Standard clearance: mm (in.)

Maximum clearance: mm (in.)

KOYO made:

KOYO made: 0.058 (0.0023)

0.015 - 0.058 (0.0006 - 0.0023)

NSK made:

NSK made: 0.056 (0.0022)

0.015 - 0.056 (0.0006 - 0.0022)

C80345

If the clearance exceed the maximum value, replace the gear,

needle roller bearing or shaft.

94. INSTALL GEAR SHIFT FORK NO.3

(a) Coat the transmission clutch hub sleeve No.3 with gear

oil, install it and gear shift fork No.3 to the transmission

clutch hub No.3.

HINT:

Do not set the transmission clutch hub No.3 in incorrect orienta-

tion.

C80401

(b) Coat the gear shift lock fork ball with sealant, install it to

the gear shift fork No.3.

Sealant:

Part No. 08833-00080, THREE BOND 1344, LOCTITE

242 or equivalent

Torque: 15.7 N m (160 kgf cm, 12 ft lbf)

C80402

95. INSTALL MANUAL TRANSMISSION OUTPUT SHAFT

REAR SET NUT

(a) Engage the gear double meshing.

(b) Install a new manual transmission output shaft rear set

nut.

Torque: 117.6 N m (1,200 kgf cm, 87 ft lbf)

C80403