Toyota Corolla (2004+). Manual - part 27

41-4

MANUAL TRANSMISSION/TRANSAXLE

- FRONT DIFFERENTIAL OIL SEAL

11. INSTALL TRANSMISSION CASE OIL SEAL

(a) Coat a new oil seal lip with MP grease.

(b) Using SST and a hammer, install the transmission case

oil seal.

SST

09554-14010, 09950-70010 (09951-07200)

Drive in depth: 9.9

0.3 mm (0.390

0.012 in.)

SST

NOTICE:

Be careful not to damage the oil seal lip.

D26133

12. INSTALL FRONT DRIVE SHAFT ASSY LH (See page 30-6)

13. INSTALL FRONT DRIVE SHAFT ASSY RH (See page 30-6)

14. INSTALL FRONT WHEELS

Torque: 103 N m (1,050 kgf cm, 76 ft lbf)

15. ADD MANUAL TRANSAXLE OIL

Oil grade: API GL-4 or GL-5

Viscosity: SAE 75 W-90

Capacity:1.9 liters (2.0 US qts, 1.7 lmp. qts)

Torque: 39.2 N m (400 kgf cm, 29 ft lbf)

0 - 5 mm

(0 - 0.20 in.)

D25304

16. INSPECT AND ADJUST MANUAL TRANSAXLE OIL (See page

41-2)

17. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT (See page 26-5)

18. CHECK ABS SPEED SENSOR SIGNAL (See page 05-297)

41-62

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

INPUT SHAFT ASSY (C59)

4107G-01

COMPONENTS

3rd Gear Needle Roller Bearing

Input Shaft

3rd Gear Synchronizer Ring

Transmission Hub Sleeve No.2

Transmission Clutch Hub No.2

4th Gear Synchronizer Ring

Snap Ring

3rd Gear

4th Gear Bearing Spacer

Input Shaft Rear Radial Ball Bearing

Shifting Key Spring No.2

Shifting Key No.2

4th Gear Needle Roller Bearing

4th Gear

Snap Ring

D07720

41-63

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

4107H-01

OVERHAUL

1.

INSPECT 4TH GEAR THRUST CLEARANCE

(a) Using a feeler gauge, measure the 4th gear thrust clear-

ance.

4th gear thrust clearance:

Standard clearance: mm (in.)

Maximum clearance: mm (in.)

0.10 - 0.55 (0.0039 - 0.0217)

0.55

(0.0217)

C80557

2.

INSPECT 3RD GEAR THRUST CLEARANCE

(a) Using a dial indicator, measure the 3rd gear thrust clear-

ance.

3rd gear thrust clearance:

Standard clearance: mm (in.)

Maximum clearance: mm (in.)

0.10 - 0.35 (0.0039 - 0.0138)

0.35

(0.0138)

C67816

3.

INSPECT 4TH GEAR RADIAL CLEARANCE

(a) Using a dial indicator, measure the 4th gear radial clear-

ance.

4th gear radial clearance:

Standard clearance:

Maximum clearance:

mm (in.)

mm (in.)

0.015

- 0.058

KOYO made

0.058

(0.0023)

(0.0006

- 0.0023)

0.015

- 0.056

C80558

NSK made

0.056

(0.0022)

(0.0006

- 0.0022)

If the clearance exceeds the maximum, replace the gear,

needle roller bearing or shaft.

41-64

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

4.

INSPECT 3RD GEAR RADIAL CLEARANCE

(a) Using a dial indicator, measure the 3rd gear radial clear-

ance.

3rd gear radial clearance:

Standard clearance:

Maximum clearance:

mm (in.)

mm (in.)

0.015

- 0.058

KOYO made

0.058

(0.0023)

(0.0006

- 0.0023)

0.015

- 0.056

C67815

NSK made

0.0056

(0.0022)

(0.0006

- 0.0022)

If the clearance exceeds the maximum, replace the gear,

needle roller bearing or shaft.

5.

REMOVE 4TH GEAR

(a) Using 2 screwdrivers and a hammer, tap out the snap

ring.

HINT:

Using a waste to prevent the snap ring from being scattered.

C80559

(b) Using SST and a press, remove the input shaft radial ball

bearing rear and 4th gear from the input shaft.

SST

09950-00020

SST

NOTICE:

F

Do not tighten SST excessively.

F

Support the input shaft assy by hand so that it will not

be dropped off.

Q04983

6.

REMOVE 4TH GEAR NEEDLE ROLLER BEARING

(a) Remove the 4th gear needle roller bearing and 4th gear

bearing spacer from the input shaft.

C80560

41-65

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

7.

REMOVE 4TH GEAR SYNCHRONIZER RING

(a) Remove the 4th gear synchronizer ring from the transmis-

sion clutch hub No.2.

C80561

8.

REMOVE 3RD GEAR

(a) Using 2 screwdrivers and a hammer, tap out the snap

ring.

HINT:

Using a waste to prevent the snap ring from being scattered.

C67821

(b) Using SST and a press, remove the transmission clutch

hub No.2 and 3rd gear from the input shaft.

SST

SST

09950-00020

NOTICE:

F

Do not tighten SST excessively.

F

Support the input shaft by hand so that it will not be

dropped off.

CM0064

9.

REMOVE 3RD GEAR SYNCHRONIZER RING

(a) Remove the 3rd gear synchronizer ring from the 3rd gear.

C68515

10. REMOVE 3RD GEAR NEEDLE ROLLER BEARING

(a) Remove the 3rd gear needle roller bearing from the input

shaft.

C67823

41-66

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

11. REMOVE TRANSMISSION HUB SLEEVE NO.2

(a) Remove the transmission hub sleeve No.2, 3 synchro-

mesh shifting keys and 2 synchromesh shifting key

springs from the transmission clutch hub No.2.

HINT:

Using a waste to prevent the shifting key and shifting key spring

from being scattered.

CM0141

12. INSPECT INPUT SHAFT

(a) Using a dial indicator, check the shaft runout.

Maximum runout: 0.015 mm(0.0006 in.)

If the runout exceeds the maximum, replace the input shaft.

CM0013

(b) Using a micrometer, measure the outer diameter of the in-

put shaft journal surface.

Input shaft outer diameter:

Standard outer diameter:

Minimum outer diameter:

Part

mm (in.)

mm (in.)

24.885

- 24.900

A

24.885

(0.9797)

(0.9797

- 0.9803)

28.985

- 29.000

B

28.985

(1.1411)

(1.1411

- 1.1417)

30.985

- 31.000

C

30.985

(1.2198)

(1.2198

- 1.2204)

24.985-25.000

D

24.985

(0.9836)

(0.9836

- 0.9842)

A

B C

D

If the outer diameter is below the minimum, replace the input

shaft.

C80562

13. INSPECT 4TH GEAR

(a) Using a cylinder gauge, measure the inside diameter of

the 4th gear.

Standard inside diameter:

34.015 - 34.031 mm (1.3391 - 1.3398 in.)

Maximum inside diameter:

34.031 mm (1.3398 in.)

If the inside diameter exceeds the maximum, replace the 4th

C67826

gear.

41-67

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

14. INSPECT 3RD GEAR

(a) Using a cylinder gauge, measure the inside diameter of

the 3rd gear.

Standard inside diameter:

36.015 - 36.031 mm (1.4179 - 1.4185 in.)

Maximum inside diameter:

36.031 mm (1.4185 in.)

If the inside diameter exceeds the maximum, replace the 3rd

C67827

gear.

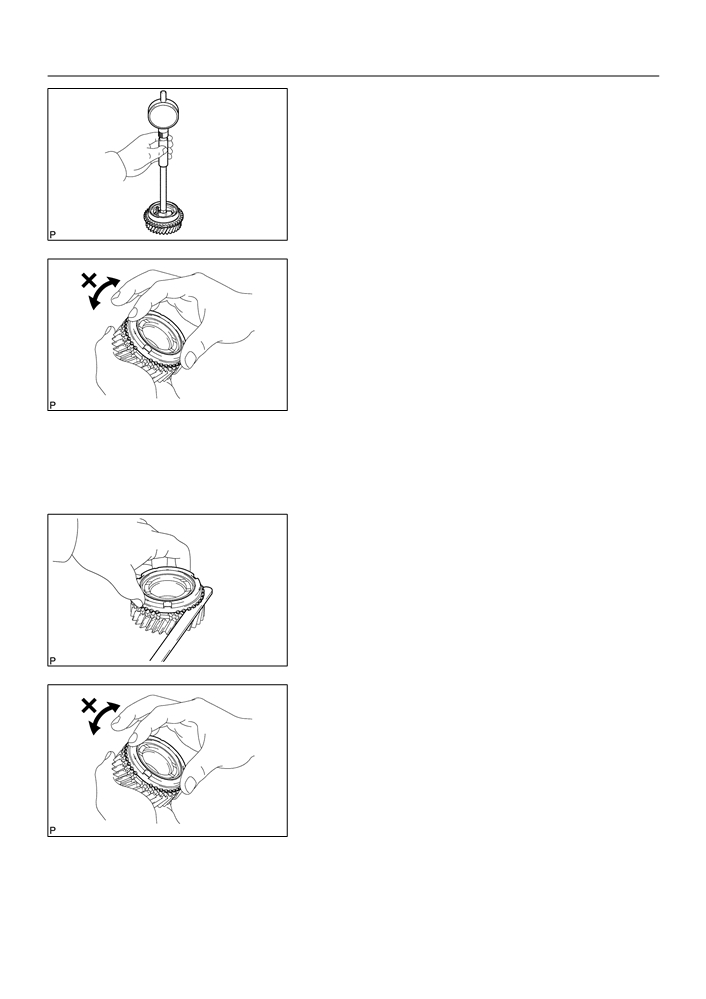

15. INSPECT 3RD GEAR SYNCHRONIZER RING

(a) Check for wear or damage.

(b) Check the braking effect of the 3rd gear synchronizer ring.

Turn the 3rd gear synchronizer ring in one direction while

pushing it to the gear cone. Check that the ring locks.

If the braking effect is insufficient, apply a small amount of the

fine lapping compound between 3rd gear synchronizer ring and

3rd gear cone. Lightly rub the 3rd gear synchronizer ring and

C80457

3rd gear cone together.

NOTICE:

Ensure the fine lapping compound is completely washed

off after rubbing.

(c)

Check again the braking effect of the synchronizer ring.

(d) Using a feeler gauge, measure the clearance between

3rd gear synchronizer ring back and 3rd gear spline end.

Minimum clearance:

0.65 mm (0.0256 in.)

If the clearance below than the minimum, replace the 3rd gear

synchronizer ring, and apply small amount of the fine lapping

compound on gear cone.

NOTICE:

C80458

Ensure the fine lapping compound is completely washed

off after rubbing.

16. INSPECT 4TH GEAR SYNCHRONIZER RING

(a) Check for wear or damage.

(b) Check the braking effect of the 4th gear synchronizer ring.

Turn the 4th gear synchronizer ring in one direction while

pushing it to the gear cone. Check that the ring locks.

If the braking effect is insufficient, apply a small amount of the

fine lapping compound between 4th gear synchronizer ring and

4th gear cone. Lightly rub the 4th gear synchronizer ring and 4th

C80457

gear cone.

NOTICE:

Ensure the fine lapping compound is completely washed

off after rubbing.

41-68

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

(c)

Using a feeler gauge, measure the clearance between

4th gear synchronizer ring back and 4th gear spline end.

Minimum clearance: 0.75 mm (0.0295 in.)

If the clearance below than the minimum, replace the 4th gear

synchronizer ring, and apply small amount of the fine lapping

compound on gear cone.

NOTICE:

Ensure the fine lapping compound is completely washed

C80458

off after rubbing.

17. INSPECT TRANSMISSION HUB SLEEVE NO.2

(a) Check the sliding condition between the transmission hub

sleeve No.2 and transmission clutch hub No.2.

(b) Check that the spline gear’s edges of the transmission

hub sleeve No.2 is not worn down.

C67843

(c)

Using a vernier caliper, inspect the transmission hub

sleeve No.2 and gear shift fork No.2 as shown in the il-

lustration.

Standard clearance:

0.15 - 0.35 mm (0.0059 - 0.0137 in.)

If the clearance is out of specification, replace the transmission

hub sleeve No.2 and gear shift fork No.2.

A

B

Clearance= (B-A)

C67842

18. INSTALL TRANSMISSION HUB SLEEVE NO.2

(a) Coat the transmission hub sleeve No.2 with gear oil,

install it to the transmission clutch hub No.2.

NOTICE:

Engine

Do not set the transmission clutch hub sleeve No.2 and the

Side

transmission clutch hub No.2 in incorrect orientation.

D02999

41-69

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

(b) Install the 2 synchromesh key springs with 3 synchro-

mesh shifting keys to the transmission clutch hub No.2.

HINT:

Do not set the both openings of the shifting key springs in the

same position.

19. INSTALL 3RD GEAR NEEDLE ROLLER BEARING

(a) Coat the 3rd gear needle roller bearing with gear oil,

install it to the input shaft.

C67823

20. INSTALL 3RD GEAR

(a) Coat the 3rd gear with gear oil, install it to the input shaft.

C67834

21. INSTALL 3RD GEAR SYNCHRONIZER RING

Key position

(a) Coat the 3rd gear synchronizer ring with gear oil, install

it to the 3rd gear.

C80463

22. INSTALL TRANSMISSION CLUTCH HUB NO.2

(a) Using SST and a press, install the transmission clutch

hub No.2 to the input shaft.

SST

09316-60011 (09316-00021)

SST

C80563

41-70

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

(b) Select a snap ring from the table below that will make the

thrust clearance of the transmission clutch hub No.2 be-

low 0.1 mm (0.0039 in.).

Snap ring thickness:

Mark

Thickness: mm (in.)

Mark

Thickness: mm (in.)

0

2.30

(0.0906)

3

2.48

(0.0976)

1

2.36

(0.0929)

4

2.54

(0.1000)

2

2.42

(0.0953)

5

2.60

(0.1024)

C67837

(c)

Using a brass bar and a hammer, tap in the snap ring.

NOTICE:

Take care not to damage the journal surface of the input

shaft.

23. INSTALL 4TH GEAR SYNCHRONIZER RING

(a) Coat the 4th gear synchronizer ring with gear oil, install it

to the transmission clutch hub No.2.

Key position

C80464

24. INSTALL 4TH GEAR NEEDLE ROLLER BEARING

(a) Coat the 4th gear needle roller bearing and 4th gear bear-

ing spacer with gear oil, install them to the input shaft.

C80560

25. INSTALL 4TH GEAR

(a) Coat the 4th gear with gear oil, install it to the input shaft.

C80564

41-71

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

26. INSTALL INPUT SHAFT REAR RADIAL BALL

BEARING

SST

(a) Using SST and a press, install the input shaft rear radial

ball bearing to the input shaft.

SST

09636-20010

C80565

(b) Select a snap ring from the table below that will make the

thrust clearance of the input shaft rear radial ball bearing

below 0.1 mm (0.0039 in.).

Snap ring thickness:

Mark

Thickness: mm (in.)

Mark

Thickness: mm (in.)

0

2.29

(0.0901)

3

2.47

(0.0972)

1

2.35

(0.0925)

4

2.53

(0.0996)

2

2.41

(0.0948)

5

2.59

(0.1019)

C80566

(c)

Using a brass bar and a hammer, tap in the snap ring.

NOTICE:

Take care not to damage the journal surface of the snap

ring.

27. INSPECT 3RD GEAR RADIAL CLEARANCE

(a) Using a dial indicator, measure the 3rd gear radial clear-

ance.

3rd gear radial clearance:

Standard clearance:

Maximum clearance:

mm (in.)

mm (in.)

0.015

- 0.058

KOYO made

0.058

(0.0023)

(0.0006

- 0.0023)

0.015

- 0.056

C67815

NSK made

0.056

(0.0022)

(0.0006

- 0.0022)

If the clearance exceeds the maximum, replace the gear,

needle roller bearing or shaft.

41-72

MANUAL TRANSMISSION/TRANSAXLE

- INPUT SHAFT ASSY (C59)

28. INSPECT 4TH GEAR RADIAL CLEARANCE

(a) Using a dial indicator, measure the 4th gear radial clear-

ance.

4th gear radial clearance:

Standard clearance:

Maximum clearance:

mm (in.)

mm (in.)

0.015

- 0.058

KOYO made

0.058

(0.0023)

(0.0006

- 0.0023)

0.015

- 0.056

C80558

NSK made

0.056

(0.0022)

(0.0006

- 0.0022)

If the clearance exceeds the maximum, replace the gear,

needle roller bearing or shaft.

29. INSPECT 3RD GEAR THRUST CLEARANCE

(a) Using a dial indicator, measure the 3rd gear thrust clear-

ance.

3rd gear thrust clearance:

Standard clearance: mm (in.)

Maximum clearance: mm (in.)

0.10 - 0.35 (0.0039 - 0.0138)

0.35

(0.0138)

C67816

30. INSPECT 4TH GEAR THRUST CLEARANCE

(a) Using a feeler gauge, measure the 4th gear thrust clear-

ance.

4th gear thrust clearance:

Standard clearance: mm (in.)

Maximum clearance: mm (in.)

0.10 - 0.55 (0.0039 - 0.0217)

0.55

(0.0217)

C80557

41-25

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

MANUAL TRANSAXLE ASSY (C59)

4107E-01

COMPONENTS

w/ ABS:

w/o ABS:

11.3 (115, 8)

Speedometer Sensor

11.3 (115, 8)

Speedometer Driven

Hole Cover Sub-assy

Clutch Release

Clip

Bearing Clip

f O-Ring

f O-Ring

Clutch Release

Speedometer

Fork Sub-assy

Driven (MTM)

Gear Sub-assy

Clutch Release

f

Transaxle Case

Floor Shift Control

Bearing Assy

Oil Seal

29.4 (300, 22)

Lever Housing Support Bracket

11.3 (115, 8)

Release

Manual Transaxle

Fork Support

Case Receiver

36.8 (375, 25)

11.3 (115, 8)

Shim

Clutch Release

Fork Boot

f

FR Differential Case Front

Transaxle Case

Transmission

Tapered Roller Bearing

Magnet

Output Shaft

(MTM) Cover

Front Transaxle

f

Output Shaft

Case Oil Seal

Front Bearing

f

Input Shaft

Bearing Lock Plate

Front Bearing

11.3 (115, 8)

Shim

fFR Differential

Differential Case Assy

Case Rear Tapered

Roller Bearing

f Transmission Case Oil Seal

Nm (kgfcm, ftlbf)

: Specified torque

f Non-reusable part

Apply MP grease

C95305

41-26

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

_ Shift Detent Ball Plug

24.5 (250, 18)

Gear Shift Fork No.1

Reverse Shift Arm

Seat

Reverse

Bracket Assy

Spring

Shift Fork

_

15.7 (160, 12)

17.2 (175, 13)

Shift Detent Ball

Snap Ring

Gear Shift Fork Shaft

Snap Ring

Sub-assy No.1

Snap

_ Shift Detent Ball Plug

Ring

24.5 (250, 18)

Seat

Reverse Idler

Spring

Thrust Washer

Gear Sub-assy

Gear Shift

Shift Detent Ball

Ball

Fork Shaft No.3

_

15.7 (160, 12)

Shift

Seat

Detent

Ball

Spring

Gear Shift Fork No.3

Reverse Idler

Gear Shaft

_ Shift Detent Ball Plug

f Gasket

24.5 (250, 18)

Gear Shift

_ Reverse Idler Gear

Fork Shaft No.2

_

15.7 (160, 12)

Shaft Bolt

29.4 (300, 22)

Snap Ring

Gear Shift Head No.1

_

15.7 (160, 12)

Output Shaft

Output Shaft Assy

Rear Bearing Hole

Gear Shift Fork No.2

Snap Ring

5th Driven Gear

f Manual Transmission

Input Shaft Assy

Output Shaft Rear Set Nut

117.6 (1,200, 87)

Input Shaft Rear

5th Gear Bearing Spacer

Bearing Hole Snap Ring

5th Gear

Synchromesh Shifting Key

Bearing Retainer Rear (MTM)

Synchromesh Shifting

_

27.4 (279, 20)

x5

Key Spring

5th Gear Needle Roller Bearing

Nm (kgfcm, ftlbf)

: Specified torque

Input Shaft Snap Ring

f Non-reusable part

_ Precoated part

Transmission Clutch Hub No.3

Z18280

41-27

MANUAL TRANSMISSION/TRANSAXLE

- MANUAL TRANSAXLE ASSY (C59)

19.6 (200, 14)

Shift & Select Lever Shaft Assy

Back Up Lamp Switch

_

40.2 (410, 30)

Lock Ball Assy No.1

_

17.2 (175, 13)

_

29.4 (300, 22)

Oil Receiver Pipe No.2

_

19.6 (200, 14)

(MTM)

24.5 (250, 18)

f Gasket

Control Shift

Reverse Restrict Pin Plug

f Gasket

Lever Bush

_

12.7 (130, 9)

Slotted Pin

Lock Ball Assy No.1

_

39.2 (400, 29)

Reverse

Restrict Pin Assy

Selecting Bellcrank Assy

Oil Receiver Pipe No. 1 (MTM)

Manual Transmission Case

17.2 (175, 13)

f Gasket

Manual Transmission

x13

Case Cover Sub-assy

Manual Transmission Filler Plug

39.2 (400, 29)

29.4 (300, 22)

18.1 (185, 14)

f Gasket

x9

Drain (MTM) Plug Sub-assy

39.2 (400, 29)

Nm (kgfcm, ftlbf)

: Specified torque

f Non-reusable part

_ Precoated part

Apply MP grease

D12108