Toyota Corolla (2004+). Manual - part 23

40-12

AUTOMATIC TRANSMISSION / TRANS

- AUTOMATIC TRANSAXLE ASSY (ATM)

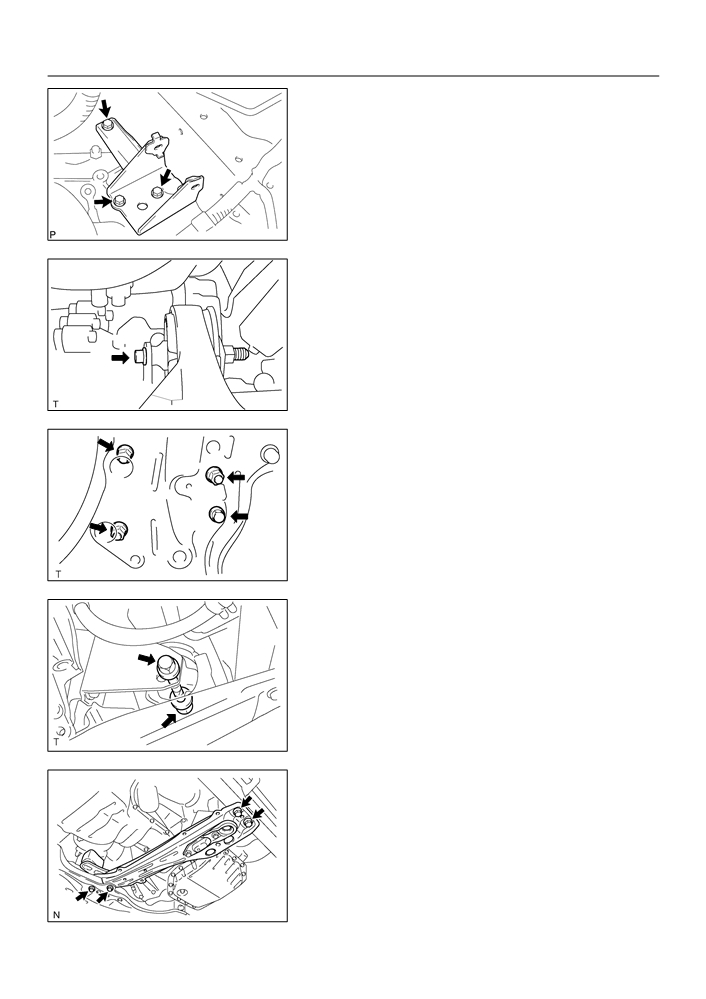

27. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING BRACKET

(a) Remove the 3 bolts and engine mounting bracket LH.

D09965

28. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING INSULATOR

(a) Remove the bolt from the engine mounting bracket RR.

C80192

(b) Remove the 3 nuts, bolt and engine mounting insulator

RR from the suspension member.

C80167

29. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING INSULATOR

(a) Remove the bolt and nut from the engine mounting brack-

et FR.

C80166

30. REMOVE ENGINE MOUNTING MEMBER SUB-ASSY

CENTER

(a) Remove the 4 bolts, dynamic damper and member sub-

assy center with engine mounting insulator FR.

C95354

40-13

AUTOMATIC TRANSMISSION / TRANS

- AUTOMATIC TRANSAXLE ASSY (ATM)

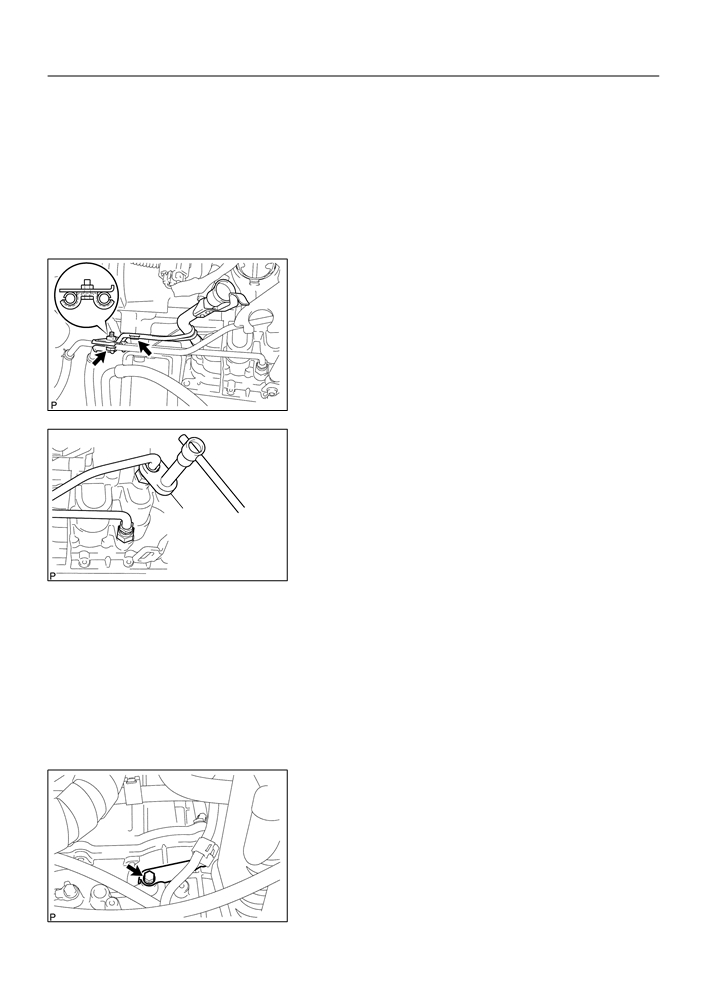

31. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING BRACKET

(a) Remove the 2 bolts and engine mounting bracket FR.

C80172

32. REMOVE TRANSVERSE ENGINE ENGINE

MOUNTING BRACKET

(a) Remove the 3 bolts and engine mounting bracket RR.

C93645

33. REMOVE FLYWHEEL HOUSING UNDER COVER

34. REMOVE AUTOMATIC TRANSAXLE ASSY

(a) Turn the crankshaft to gain access and remove the 6 bolts

while holding the crankshaft pulley bolt with a wrench.

F00478

(b) Remove the 6 bolts.

(c)

Separate and remove the automatic transaxle.

D09966

35. REMOVE TORQUE CONVERTER CLUTCH ASSY

36. INSPECT TORQUE CONVERTER CLUTCH ASSY (See page 40-20)

SST

09350-32014 (09351-32010, 09351-32020)

40-14

AUTOMATIC TRANSMISSION / TRANS

- AUTOMATIC TRANSAXLE ASSY (ATM)

37. INSTALL TORQUE CONVERTER CLUTCH ASSY

(a) Install the torque converter clutch to the automatic trans-

axle.

(b) Using vernier calipers, measure the dimension ”A” be-

tween the transaxle fitting part and the converter fitting

part of the drive plate.

C63993

(c)

Using vernier calipers and a straight edge, measure the

dimension ”B” shown in the illustration and check that ”B”

is greater than ”A” measured in (b).

Standard: A + 1 mm or more

NOTICE:

Do not add the thickness of straight edge.

C65911

38. INSTALL AUTOMATIC TRANSAXLE ASSY

(a) Install the automatic transaxle and 6 bolts to the engine.

Torque:

A

Bolt A: 64 N m (650 kgf cm, 47 ft lbf)

B

Bolt B: 46 N m (470 kgf cm, 34 ft lbf)

C

Bolt C: 23 N m (235 kgf cm, 17 ft lbf)

D09966

(b) Install the 6 torque converter mounting bolts.

Torque: 28 N m (285 kgf cm, 20 ft lbf)

HINT:

First install yellowish green colored bolt and then the 5 bolts.

F00478

39. INSTALL FLYWHEEL HOUSING UNDER COVER

40-15

AUTOMATIC TRANSMISSION / TRANS

- AUTOMATIC TRANSAXLE ASSY (ATM)

40. INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

BRACKET

(a) Install the engine mounting bracket RR and 3 bolts to the

automatic transaxle.

Torque: 64 N m (652 kgf cm, 47 ft lbf)

C93645

41. INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

BRACKET

(a) Install the engine mounting bracket FR and 2 bolts to the

automatic transaxle.

Torque: 64 N m (652 kgf cm, 47 ft lbf)

C80172

42. INSTALL ENGINE MOUNTING MEMBER SUB-ASSY

A

CENTER

A

(a) Install the dynamic damper, member sub-assy center

with engine mounting insulator FR and 4 bolts.

Torque:

Bolt A: 39 N m (398 kgf cm, 29 ft lbf)

Bolt B: 52 N m (530 kgf cm, 38 ft lbf)

B

B

C95354

43. INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

INSULATOR

(a) Install the engine mounting insulator RR and bolt to the

engine mounting bracket RR.

Torque: 87 N m (887 kgf cm, 64 ft lbf)

C80192

(b) Tighten the 3 nuts and bolt.

Torque: 52 N m (530 kgf cm, 38 ft lbf)

C80167

40-16

AUTOMATIC TRANSMISSION / TRANS

- AUTOMATIC TRANSAXLE ASSY (ATM)

44. INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

BRACKET

(a) Install the engine mounting bracket LH and 3 bolts to the

automatic transaxle.

Torque: 52 N m (530 kgf cm, 38 ft lbf)

D09965

45. INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

A

A

INSULATOR

(a) Install the engine mounting insulator LH, 5 bolts and nut.

A

B

Torque:

Bolt A: 52 N m (530 kgf cm, 38 ft lbf)

Bolt B: 80 N m (815 kgf cm, 59 ft lbf)

Nut B: 80 N m (815 kgf cm, 59 ft lbf)

B

A

D09964

46. INSTALL TRANSVERSE ENGINE ENGINE MOUNTING

INSULATOR

(a) Install the bolt and nut to the engine mounting bracket FR.

Torque: 52 N m (530 kgf cm, 38 ft lbf)

C80166

47. INSTALL STARTER ASSY

(a) Install the starter and 2 bolts.

Torque: 39 N m (400 kgf cm, 29 ft lbf)

(b) Connect the connecter.

(c)

Install the starter wire and nut.

Torque: 13 N m (132 kgf cm, 10 ft lbf)

48. INSTALL AUTOMATIC TRANSMISSION CASE PROTECTOR

(a) Install the case protector with the 2 bolts.

Torque: 18 N m (182 kgf cm, 14 ft lbf)

49. INSTALL FRONT DRIVE SHAFT ASSY LH (See page 30-6)

50. INSTALL FRONT DRIVE SHAFT ASSY RH (See page 30-6)

51. INSTALL EXHAUST PIPE ASSY FRONT (See page 15-2)

52. INSTALL ENGINE UNDER COVER LH

53. INSTALL ENGINE UNDER COVER RH

54. INSTALL FRONT WHEELS

Torque: 103 N m (1,050 kgf cm, 76 ft lbf)

55. INSTALL OXYGEN SENSOR CONNECTOR

(a) Connect the oxygen sensor connector.

(b) Install the floor carpet and foot rest.

40-17

AUTOMATIC TRANSMISSION / TRANS

- AUTOMATIC TRANSAXLE ASSY (ATM)

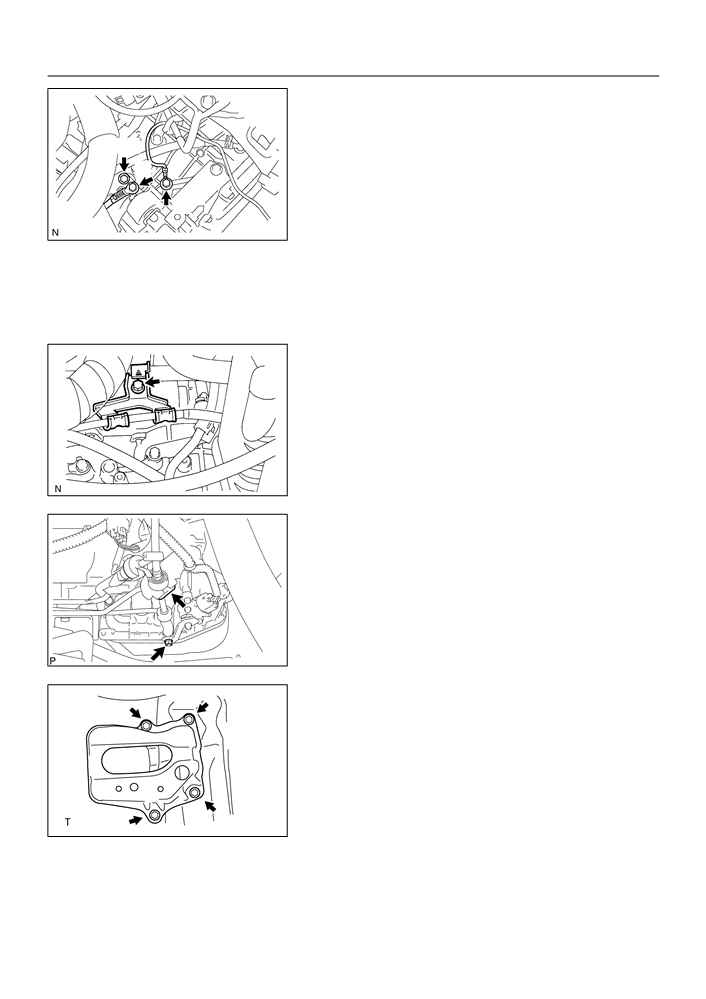

56. INSTALL TRANSMISSION OIL FILLER TUBE

SUB-ASSY

(a) Temporarily install the oil cooler outlet tube No. 1.

(b) Temporarily install the oil cooler inlet tube No. 1.

(c)

Coat a new O-ring with ATF, and install them to the oil filler

tube.

(d) Install the oil filler tube to the automatic transaxle.

(e) Install the oil cooler tube clamp and 2 bolts.

Torque: 5.5 N m (56 kgf cm, 49 in. lbf)

(f)

Install the ATF lever gauge.

D09962

57. INSTALL OIL COOLER INLET TUBE NO.1

(a) Using SST, tighten the oil cooler inlet tube No. 1.

SST

09023-12700

Torque: 34.5 N m (350 kgf cm, 25 ft lbf)

SST

C93646

58. INSTALL OIL COOLER OUTLET TUBE NO.1

(a) Using SST, tighten the oil cooler outlet tube No. 1.

SST

09023-12700

Torque: 34.5 N m (350 kgf cm, 25 ft lbf)

59. CONNECT CONNECTOR

(a) Connect the transmission wire connector.

(b) Connect the park/neutral position switch connector.

(c)

w/o ABS:

Connect the speedometer sensor connector.

60. INSTALL WIRE HARNESS

(a) Install the wire harness clamp bracket and bolt.

Torque: 12.75 N m (130 kgf cm, 9 ft lbf)

C93643

40-18

AUTOMATIC TRANSMISSION / TRANS

- AUTOMATIC TRANSAXLE ASSY (ATM)

(b) Install the wire harness clamp bracket and 2 wire har-

nesses with the 3 bolts.

Torque:

A

Bolt A: 25.5 N m (260 kgf cm, 19 ft lbf)

Bolt B: 10 N m (102 kgf cm, 7 ft lbf)

C

Bolt C: 13 N m (132 kgf cm, 10 ft lbf)

B

C93666

61. INSTALL TRANSMISSION CONTROL CABLE BRACKET NO.1

(a) Install the control cable bracket and 2 bolts.

Torque: 12 N m (122 kgf cm, 9 ft lbf)

62. INSTALL TRANSMISSION CONTROL CABLE

SUPPORT

(a) Install the control cable support and bolt.

Torque: 12 N m (122 kgf cm, 9 ft lbf)

(b) Connect the control cable and wire harness to the control

cable support.

C95750

63. INSTALL FLOOR SHIFT CABLE TRANSMISSION

CONTROL SHIFT

(a) Temporarily install the control cable to the control shaft le-

ver with the nut.

(b) Install the control cable and clip to the bracket.

C96147

64. INSTALL BATTERY CARRIER

(a) Install the battery carrier and 4 bolts.

Torque: 13 N m (132 kgf cm, 10 ft lbf)

C80159

65. INSTALL AIR CLEANER ASSEMBLY WITH HOSE

Torque: 7.0 N m (71 kgf cm, 62 in. lbf)

66. INSTALL CYLINDER HEAD COVER NO.2

Torque: 7.0 N m (71 kgf cm, 62 in. lbf)

40-19

-

AUTOMATIC TRANSMISSION / TRANS

AUTOMATIC TRANSAXLE ASSY (ATM)

67. INSTALL HOOD SUB-ASSY

Torque: 13 N m (130 kgf cm, 10 ft lbf)

68. INSPECT HOOD SUB-ASSY (See page 75-1)

69. ADJUST HOOD SUB-ASSY (See page 75-1)

70. ADD AUTOMATIC TRANSAXLE FLUID

71. INSPECT AUTOMATIC TRANSAXLE FLUID (See page 40-2)

72. ADJUST SHIFT LEVER POSITION (See page 40-44)

73. INSPECT SHIFT LEVER POSITION (See page 40-44)

74. INSPECT FRONT WHEEL ARIMENT (See page 26-5)

75. CHECK ABS SPEED SENSOR SIGNAL (W/ ABS) (See page

05-297)

40-44

AUTOMATIC TRANSMISSION / TRANS

- FLOOR SHIFT ASSY (ATM)

400LS-01

ADJUSTMENT

1.

INSPECT SHIFT LEVER POSITION

(a)

When shifting the shift lever to each position, make sure

that it moves smoothly, and the position indicator displays

correctly.

Positions which can be shifted without pressing the

shift lever knob button

R N D, L 2 D N

Positions which can be operated only while pressing

the shift lever knob button

D 2 L, N R P

Positions which can be operated only while pressing

With the brake pedal depressed,

the shift lever knob button, ignition switch ON and

shift while holding the shift lever

brake pedal depressed

knob button in. (The ignition

P R

switch must be in ON position.)

(b)

Start the engine and make sure that the vehicle moves

Shift while holding the shift

forward when shifting the lever from N to D position, and

lever knob button in.

moves rearward when shifting to R position.

Shift normally

C95423

2.

ADJUST SHIFT LEVER POSITION

(a)

Loosen the nut on the control shaft lever.

D25118

(b) Push the control shaft fully downward.

(c)

Return the control shaft lever 2 notches to N position.

(d) Set the shift lever to N position.

(e) While holding the shift lever lightly toward the R position

side, tighten the shift lever nut.

Torque: 12 N·m (122 kgf·cm, 9 ft·lbf)

(f)

Start the engine and make sure that the vehicle moves

forward when shifting the lever from N to D position and

D25119

moves rearward when shifting it to R position.

40-32

AUTOMATIC TRANSMISSION / TRANS

- FLOOR SHIFT ASSY (ATM)

FLOOR SHIFT ASSY (ATM)

400LQ-01

COMPONENTS

Console Panel Upper

Console Box Carpet

Parking Brake Hole Cover Sub-assy

Console Box Sub-assy Rear

Floor Shift Parking Lock Cable Assy

12 (122, 9)

12 (122, 9)

Floor Shift Cable Transmission

Control Shift

Floor Shift Assy

Nm (kgfcm, ftlbf)

: Specified torque

C95783

40-33

AUTOMATIC TRANSMISSION / TRANS

- FLOOR SHIFT ASSY (ATM)

Shift Lock Release Button

Position Indicator Housing Lower

Spring

Shift Lever Knob Sub-assy

Transmission Control Switch

Spring

Shift Lever

Cap

F

Knob Cover

Bulb

Indicator Lamp Wire Sub-assy

Shift Lever Knob Button

Shift Lock Release Button Cover

Position Indicator Housing Upper

Shift Lock Control

Toggle Lever

Unit Assy

Support Pin

Position Indicator

Control Position

Slide Cover

Indicator Plate

Shift Lever Insert No.1

Shift Lever Plate Sub-assy

C93668

Shift Lever

Insert No.1

F Precoated part

Apply MP grease

C93668

40-34

AUTOMATIC TRANSMISSION / TRANS

- FLOOR SHIFT ASSY (ATM)

400LR-01

OVERHAUL

1.

REMOVE CONSOLE PANEL UPPER (See page 71-10)

2.

REMOVE CONSOLE BOX CARPET (See page 71-10)

3.

REMOVE PARKING BRAKE HOLE COVER SUB-ASSY (See page

71-10)

4.

REMOVE CONSOLE BOX SUB-ASSY REAR (See page 71-10)

5.

DISCONNECT FLOOR SHIFT CABLE TRANSMISSION

CONTROL SHIFT

(a) Remove the cable end from the rod of the floor shift as-

sembly.

C93669

(b) Using a screw driver, disconnect the control cable from

the shift lever plate.

C94276

6.

DISCONNECT FLOOR SHIFT PARKING LOCK CABLE

ASSY

(a) Remove the cable end from the lever pin of the floor shift

assembly.

C93670

(b) Using a screw driver, disconnect the parking lock cable

from the floor shift assembly.

7.

REMOVE FLOOR SHIFT ASSY

(a) Disconnect the 2 connector.

C94278

40-35

AUTOMATIC TRANSMISSION / TRANS

- FLOOR SHIFT ASSY (ATM)

(b) Disconnect the 2 wire harness clamps from the shift lever

assy.

(c)

Remove the 4 bolts and floor shift assy.

C93671

8.

REMOVE FLOOR SHIFT SHIFT LEVER KNOB

SUB-ASSY

(a) Releasing the lock by pressing the slick, disconnect the

indicator lamp wire connector from the shift lever plate.

C93672

(b) Disengage the secondary locking device.

1

Secondary Locking Device

(c)

Using a small screwdriver, disengage the locking lug of

the terminals 2 and 4, and pull the terminals out from the

rear.

(d) Disconnect the wire harness from the clamps.

4

2

3

2

C95784

(e) Remove the 2 screws and shift lever knob sub-assembly.

NOTICE:

Pay attention not to apply unnatural load to transmission

control switch wire harness.

C93673

9.

REMOVE FLOOR SHIFT SHIFT LEVER KNOB COVER

(a) Remove the shift lever knob cover.

C93674

40-36

AUTOMATIC TRANSMISSION / TRANS

- FLOOR SHIFT ASSY (ATM)

10. REMOVE TRANSMISSION CONTROL SWITCH

(a) Using a small screw driver, remove the transmission con-

trol switch.

C93675

11. REMOVE SHIFT LEVER KNOB BUTTON

(a) Remove the shift lever knob button and spring.

C93676

12. REMOVE INDICATOR LAMP WIRE SUB-ASSY

(a) Remove the indicator lamp wire sub-assy.

(b) Remove the cap and bulb from the indicator lamp wire

sub-assy.

C93677

13. REMOVE SHIFT LOCK RELEASE BUTTON COVER

(a) Using a screwdriver, remove the shift lock release button

cover.

C93678

14. REMOVE POSITION INDICATOR HOUSING UPPER

(a) Using a screwdriver, release the 4 claws and remove the

position indicator housing upper.

C93679

40-37

AUTOMATIC TRANSMISSION / TRANS

- FLOOR SHIFT ASSY (ATM)

15. REMOVE CONTROL POSITION INDICATOR PLATE

(a) Remove the position indicator plate from the position indi-

cator housing upper.

C93680

16. REMOVE POSITION INDICATOR SLIDE COVER

(a) Remove the position indicator slide cover.

C95340

17. REMOVE POSITION INDICATOR HOUSING LOWER

(a) Using a screwdriver, release the 3 claws and remove the

position indicator housing lower.

C95341

18. REMOVE SHIFT LOCK RELEASE BUTTON

(a) Remove the shift lock release button and spring.

C95342

19. REMOVE SHIFT LOCK CONTROL UNIT ASSY

(a) Using a screwdriver, remove the toggle lever support pin

and shift lock control unit assy.

NOTICE:

Work so as not to damage the stopper position.

Stopper

C95343