Toyota Corolla (2004+). Manual - part 19

32-22

BRAKE

- BRAKE BOOSTER ASSY

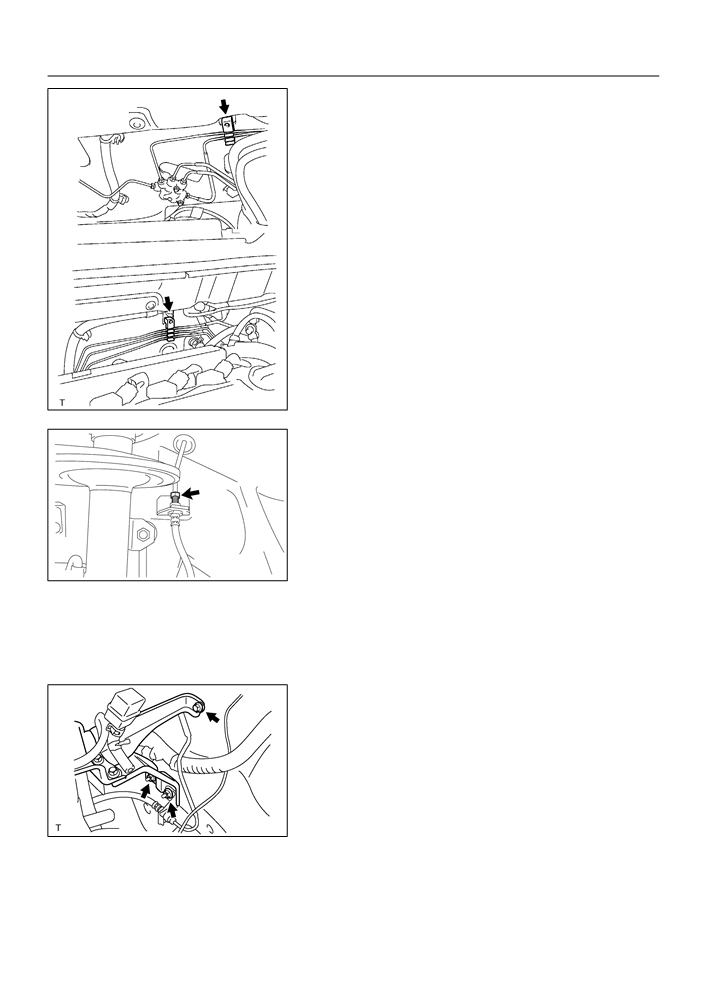

(c)

Connect the 2 or 3 brake tubes to the clamp.

w/o ABS:

(d) Connect the vacuum hose to the brake booster.

w/ ABS:

F42814

(e) Using SST and spanner, connect the brake tube to the

flexible hose.

SST

09023-00100

Torque: 15.2 N m (155 kgf cm, 11 ft lbf)

F40019

10. INSTALL FRONT WHEEL LH

Torque: 103 N m (1,050 kgf cm, 76 ft lbf)

11. INSTALL CRUISE CONTROL ACTUATOR ASSY (W/

CRUISE CONTROL)

(a) Install the cruise control actuator and bracket with 2 nuts

and bolt.

Torque: 43 N m (438 kgf cm, 32 ft lbf)

F42813

12. CONNECT BRAKE MASTER CYLINDER PUSH ROD CLEVIS

(a) Apply the lithium soap base glycol grease to the push rod clevis pin.

(b) Connect the brake master cylinder push rod clevis with the push rod clevis pin, wave washer and clip.

13. INSTALL BRAKE MASTER CYLINDER SUB-ASSY (See page

32-13)

32-23

BRAKE

-

BRAKE BOOSTER ASSY

14. INSTALL AIR CLEANER CASE SUB-ASSY

(a) Install the air cleaner case with 3 bolts, then install the air cleaner element to the air cleaner case sub-

assy.

15. INSTALL AIR CLEANER CAP SUB-ASSY

16. FILL RESERVOIR WITH BRAKE FLUID

17. BLEED MASTER CYLINDER (See page 32-4)

SST

09023-00100

18. BLEED BRAKE LINE (See page

32-4)

19. CHECK AND ADJUST BRAKE PEDAL HEIGHT (See page

32-6)

20. CHECK PEDAL FREE PLAY (See page 32-6)

21. CHECK PEDAL RESERVE DISTANCE (See page 32-6)

22. CHECK FLUID LEVEL IN RESERVOIR

23. CHECK BRAKE FLUID LEAKAGE

32-11

BRAKE

- BRAKE MASTER CYLINDER SUB-ASSY (April, 2003)

BRAKE MASTER CYLINDER SUB-ASSY (April, 2003)

320ZN-01

COMPONENTS

w/ ABS:

No.1 Way

15.2 (155, 11)

Brake Fluid Level

Switch Connector

Brake Booster Assy

Brake Master Cylinder

Sub-assy

15.2 (155, 11)

15.2 (155, 11)

Vacuum Check

Valve Bracket

No.1 Way

M/T:

Clip

15.2 (155, 11)

M/T:

12.5 (127, 9)

Clutch Reservoir

Tube No.1

15.2 (155, 11)

Air Cleaner Cap Sub-assy

N·m (kgf·cm, ft·lbf)

: Specified torque

C86271

32-12

BRAKE

- BRAKE MASTER CYLINDER SUB-ASSY (April, 2003)

A/T:

Master Cylinder

Reservoir Sub-assy

Cap

Strainer

Master Cylinder

Reservoir Sub-assy

Grommet

F

O-Ring

Grommet

Master Cylinder

F

Gasket

F

Piston Stopper Bolt

Snap Ring

10 (102, 7)

Reservoir Stopper Screw

1.8 (18.4, 15.9 in.·lbf)

No. 1 Piston Sub-assy

No. 2 Piston Sub-assy

: Specified torque

N·m (kgf·cm, ft·lbf)

F Non-reusable part

Lithium soap base glycol grease

C86272

32-13

BRAKE

- BRAKE MASTER CYLINDER SUB-ASSY (April, 2003)

320IE-02

OVERHAUL

1.

DRAIN BRAKE FLUID

NOTICE:

Wash the brake fluid off immediately if it comes into contact with any painted surface.

2.

REMOVE AIR CLEANER CAP SUB-ASSY

3.

REMOVE BRAKE MASTER CYLINDER SUB-ASSY

(a) Disconnect the brake fluid level switch connector from

master cylinder reservoir sub-assy.

(b) M/T:

Slide the clip and disconnect the clutch reservoir tube

No.1 from master cylinder reservoir sub-assy.

(c)

Using SST, disconnect the 2 brake tubes from the master

cylinder.

SST

09023-00100

SST

F42809

(d) Using SST, disconnect the 2 or 3 brake tubes from the

w/o ABS:

No.1 way.

SST

09023-00100

w/ ABS:

F42810

32-14

BRAKE

- BRAKE MASTER CYLINDER SUB-ASSY (April, 2003)

(e) Remove the 2 nuts, and pull out the master cylinder, No.1

way and vacuum check valve bracket.

F42811

4.

REMOVE BRAKE MASTER CYLINDER RESERVOIR SUB-ASSY

(a) Remove the reservoir stopper screw and master cylinder reservoir sub-assy.

(b) Remove the 2 cylinder reservoir grommets.

5.

REMOVE BRAKE MASTER CYLINDER KIT

(a) Hold the master cylinder in the vise with the 2 aluminum

plates in between.

(b) Remove the O-ring.

(c)

Push in the piston and remove the snap ring with snap

ring pliers.

F40004

(d) Push in the piston and remove the piston stopper bolt and

gasket.

(e) Remove the No.1 piston sub-assy by hand, pulling

straight out not at an angle.

NOTICE:

If being pulled out at an angle, the piston may damage the

cylinder bore.

C69097

(f)

Place a cloth and 2 wooden blocks on the work table and

lightly edges until the No.2 piston sub-assy drops out of

the cylinder.

NOTICE:

If being pulled out at an angle, the piston may damage the

cylinder bore.

HINT:

(A)

Make sure that the distance (A) from the cloth to the top of the

R12236

blocks is at least 100 mm (3.94 in.).

32-15

BRAKE

- BRAKE MASTER CYLINDER SUB-ASSY (April, 2003)

6.

INSPECT BRAKE MASTER CYLINDER

(a)

Check the cylinder bore for rust or scoring.

7.

INSTALL BRAKE MASTER CYLINDER KIT

(a) Hold the master cylinder in the vise with the 2 aluminum

plates in between.

(b) Apply the lithium soap base glycol grease to the No.1 and

No.2 piston sub-assy.

(c)

Install the No.2 and No.1 piston sub-assy to the master

cylinder.

NOTICE:

F

If being inserted at an angle, the piston may damage

the cylinder bore.

F

Be careful not to damage the rubber lips on the pis-

tons.

(d) Push in the piston and install a new gasket and a new pis-

ton stopper bolt.

Torque: 10 N m (102 kgf cm, 7 ft lbf)

C69097

(e) Push in the piston and install the snap ring with snap ring

pliers.

(f)

Apply the lithium soap base glycol grease to a new O-

ring, and install the O-ring to the master cylinder.

F40004

8.

INSTALL BRAKE MASTER CYLINDER RESERVOIR SUB-ASSY

(a) Apply the lithium soap base glycol grease to 2 brake master cylinder reservoir grommets.

(b) Install the master cylinder reservoir with the screw.

Torque: 1.8 N m (18.4 kgf cm, 15.9 in. lbf)

9.

INSPECT AND ADJUST B RAKE BOOSTER PUSH

ROD

SST

(a) Apply the chalk to the flat surfaced tip of the SST pin.

(b) Set SST on the master cylinder and lower the pin of the

SST until it slightly touches the piston.

SST

09737-00013

C94955

F42864

32-16

BRAKE

- BRAKE MASTER CYLINDER SUB-ASSY (April, 2003)

(c)

Turn SST upside down and place it on the brake booster.

SST

SST

09737-00013

Clearance: 0 mm (0 in.)

HINT:

F

If there is a space between the SST main body and the

booster shell (chalk is applied to the booster push rod), it

means that the clearance is too small.

F

If chalk is not applied to the booster push rod after placing

SST

F42815

the SST on the brake booster, it means that the clearance

is too large.

(d) If clearance is outside of the specified range, fix the push

rod using SST and adjust the length of the protruding ad-

justing bolt.

SST

09737-00020

HINT:

When adjusting the push rod, depress the brake pedal suffi-

ciently so that the push rod sticks out.

SST

F42816

10. INSTALL BRAKE MASTER CYLINDER SUB-ASSY

(a) Install the master cylinder, No.1 way and vacuum check

valve bracket with the 2 nuts.

Torque: 12.5 N m (127 kgf cm, 9 ft lbf)

F42811

(b) Using SST, connect the 2 or 3 brake tubes to the No.1

w/o ABS:

way.

SST

09023-00100

Torque: 15.2 N m (155 kgf cm, 11 ft lbf)

w/ ABS:

F42810

32-17

BRAKE

- BRAKE MASTER CYLINDER SUB-ASSY (April, 2003)

(c)

Using SST, connect the 2 brake tubes to the master cylin-

der.

SST

09023-00100

Torque: 15.2 N m (155 kgf cm, 11 ft lbf)

(d) M/T:

Connect the clutch reservoir tube No.1 with the clip to

master cylinder reservoir sub-assy.

(e) Connect the brake fluid level switch connector to master

SST

F42809

cylinder reservoir sub-assy.

11. INSTALL AIR CLEANER CAP SUB-ASSY

12. FILL RESERVOIR WITH BRAKE FLUID

13. BLEED MASTER CYLINDER (See page 32-4)

SST

09023-00100

14. BLEED BRAKE LINE (See page

32-4)

15. CHECK FLUID LEVEL IN RESERVOIR

16. CHECK BRAKE FLUID LEAKAGE

32-6

BRAKE

- BRAKE PEDAL SUB-ASSY

BRAKE PEDAL SUB-ASSY

320IA-01

ADJUSTMENT

1.

CHECK AND ADJUST BRAKE PEDAL HEIGHT

Stop Lamp Switch

(a)

Inspect brake pedal height.

Pedal height from asphalt sheet:

M/T: 134.9 - 144.9 mm (5.311 - 5.703 in.)

A/T: 136.0 - 146.0 mm (5.353 - 5.747 in.)

(1)

Disconnect the connector from the stop lamp

switch.

(2)

Remove the stop lamp switch.

(3)

Loosen the clevis lock nut.

(4)

Adjust the pedal height by turning the pedal push

rod.

Push Rod

(5)

Tighten the push rod lock nut.

Torque: 26 N m (265 kgf cm, 19 ft lbf)

(6)

Install the stop lamp switch.

(7)

Connect the connector to the stop lamp switch.

(8)

Push the brake pedal in 5 - 15 mm (0.20 - 0.59 in.),

Pedal Height

and turn the stop lamp switch to lock the nut in the

position where the stop lamp goes off.

F40001

(9)

After installation, push the brake pedal in 5 - 15 mm

(0.20 - 0.59 in.), check that stop lamp comes on.

2.

CHECK PEDAL FREE PLAY

(a)

Stop the engine and depress the brake pedal several

times until there is no more vacuum left in the booster.

(b)

Push in the pedal until the beginning of the resistance is

felt. Measure the distance, as shown in the installation.

Pedal free play: 1 - 6 mm (0.04 - 0.24 in.)

If incorrect, check the stop lamp switch clearance.

If the clearance is OK, then troubleshoot the brake system.

Stop lamp switch clearance:

0.5 - 2.4 mm (0.020 - 0.094 in.)

Pedal Free Play

F40002

32-7

BRAKE

- BRAKE PEDAL SUB-ASSY

3.

CHECK PEDAL RESERVE DISTANCE

(a) Release the parking brake lever.

With engine running, depress the pedal and measure the

pedal reserve distance, as shown in the installation.

Pedal reserve distance from asphalt sheet at 490 N

(50 kgf, 110.2 lbf): More than 70 mm (2.76 in.)

If incorrect, troubleshoot the brake system.

Pedal Reserve

Distance

R00934

32-8

BRAKE

- BRAKE PEDAL SUB-ASSY

320IB-01

COMPONENTS

Meter Hood Sub-assy

Combination Meter Assembly

23.6 (240, 17)

Brake Pedal

Stop Lamp Switch Connector

Support Sub-assy

Stop Lamp Switch Assy

F Bush

36.8 (375, 27)

F Bush

12.7 (130, 9)

Push Rod Clevis Pin

Wave Washer

Brake Pedal Sub-assy

Brake Master Cylinder

Push Rod Clevis

A/T:

Clip

Brake Pedal Sub-assy

Brake Pedal Pad

Brake Pedal Pad

N·m (kgf·cm, ft·lbf)

: Specified torque

F Non-reusable part

Lithium soap base glycol grease

F42828

32-9

BRAKE

- BRAKE PEDAL SUB-ASSY

320IC-01

REPLACEMENT

1.

REMOVE COMBINATION METER ASSEMBLY (See page 71-17)

2.

DISCONNECT BRAKE MASTER CYLINDER PUSH ROD CLEVIS

(a) Remove the clip and push rod clevis pin and wave washer, and disconnect the push rod clevis from

the brake pedal.

3.

REMOVE BRAKE PEDAL SUPPORT SUB-ASSY

(a) Remove the bolt from the brake pedal support.

(b) Disconnect the stop lamp switch connector.

F42280

(c)

Remove the 4 nuts and brake pedal support assy.

F42862

4.

REMOVE BRAKE PEDAL SUB-ASSY

(a) Remove the bolt and nut from the brake pedal support sub-assy.

(b) Remove the brake pedal sub-assy and 2 bushes.

5.

REMOVE STOP LAMP SWITCH ASSY

(a) Loosen the stop lamp switch lock nut.

(b) Remove the stop lamp switch assy from the brake pedal support sub-assy.

6.

REMOVE BRAKE PEDAL PAD

(a) Remove the brake pedal pad from the brake pedal sub-assy.

7.

INSTALL BRAKE PEDAL PAD

(a) Install the brake pedal pad to the brake pedal sub-assy.

8.

INSTALL STOP LAMP SWITCH ASSY

(a) Install the stop lamp switch assy to the brake pedal sub-assy.

9.

INSTALL BRAKE PEDAL SUB-ASSY

(a) Apply the lithium soap base glycol grease to the 2 new bushes on the ends and sides.

(b) Install the brake pedal sub-assy and 2 bushes to the brake pedal support with the bolt and nut.

Torque: 36.8 N m (375 kgf cm, 27 ft lbf)

32-10

BRAKE

- BRAKE PEDAL SUB-ASSY

10. INSTALL BRAKE PEDAL SUPPORT SUB-ASSY

(a) Install the brake pedal support assy with the 4 nuts.

Torque: 12.7 N m (130 kgf cm, 9 ft lbf)

(b) Connect the stop lamp switch connector to the stop lamp

switch assy.

F42862

(c)

Install the bolt to the brake pedal support sub-assy.

Torque: 23.6 N m (240 kgf cm, 17 ft lbf)

F42280

11. CONNECT BRAKE MASTER CYLINDER PUSH ROD CLEVIS

(a) Apply the lithium soap base glycol grease to the push rod clevis pin.

(b) Connect the brake master cylinder push rod clevis with the push rod clevis pin, wave washer and clip.

12. INSTALL COMBINATION METER ASSEMBLY

13. CHECK AND ADJUST BRAKE PEDAL HEIGHT (See page

32-6)

14. CHECK PEDAL FREE PLAY (See page 32-6)

15. CHECK PEDAL RESERVE DISTANCE (See page 32-6)

32-4

BRAKE

- BRAKE FLUID

BRAKE FLUID

320I9-01

BLEEDING

NOTICE:

Wash the brake fluid off immediately if it comes into contact with any painted surface.

HINT:

If any work is done on the brake system or if air in the brake lines is suspected, bleed the air from the system.

1.

FILL RESERVOIR WITH BRAKE FLUID

Fluid: SAE J1703 or FMVSS No. 116 DOT3

C80823

2.

BLEED MASTER CYLINDER

HINT:

If the master cylinder has been disassembled or if the reservoir

becomes empty, bleed the air from the master cylinder.

(a) Disconnect the brake lines from the master cylinder.

SST

09023-00100

(b) Slowly depress the brake pedal and hold it.

C80824

(c)

Block off the outer holes with your fingers, and release the

brake pedal.

(d) Repeat (b) and (c) 3 or 4 times.

F42863

3.

BLEED BRAKE LINE

(a) Connect the vinyl tube to the brake caliper.

(b) Depress the brake pedal several times, then loosen the

bleeder plug with the pedal held down.

(c)

At the point when fluid stops coming out, tighten the

bleeder plug, then release the brake pedal.

Torque: 8.3 N m (85 kgf cm, 74 in. lbf)

(d) Repeat (b) and (c) until all the air in the fluid has been bled

C80826

out.