SsangYong Rexton. Service manual - part 552

AUTOMATIC TRANSMISSION 5A-183

SSANGYONG Y200

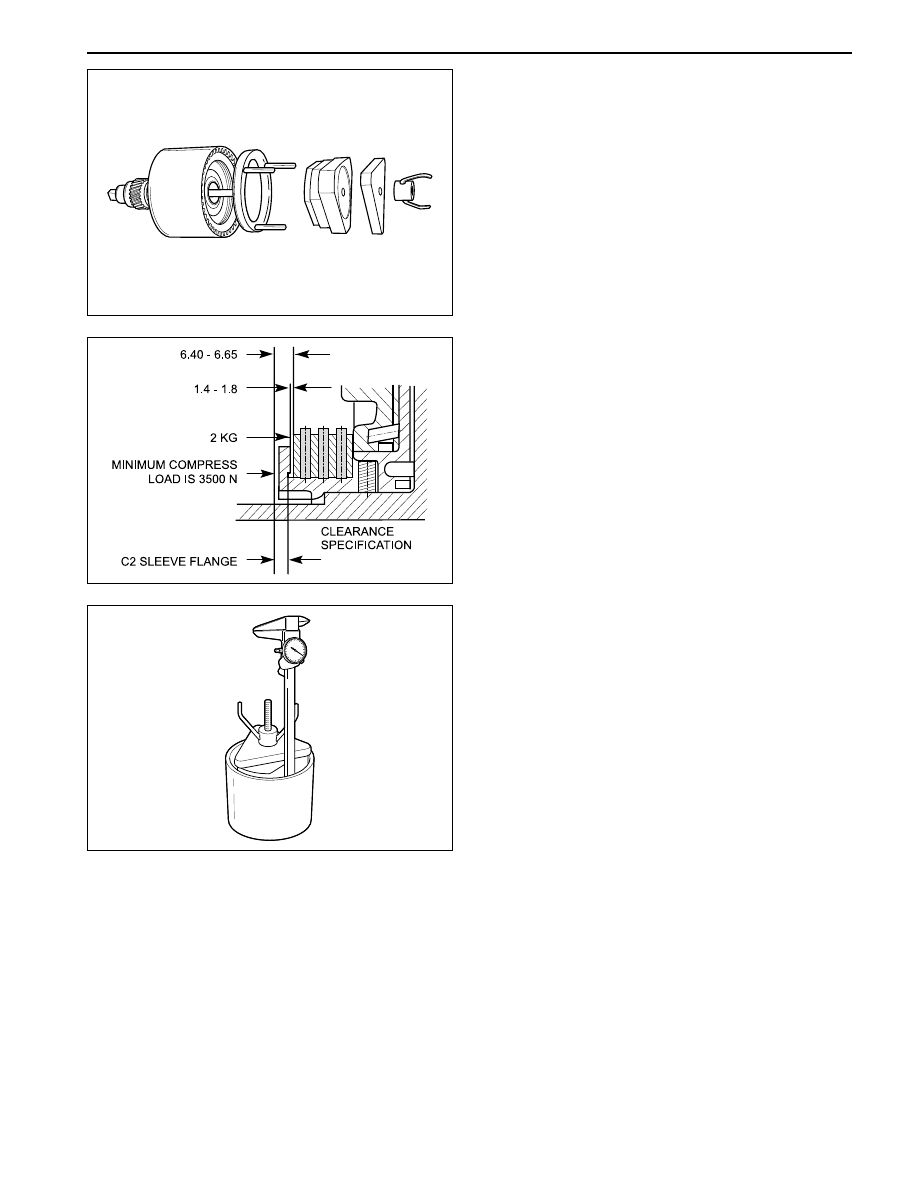

24. Reassemble the sleeve and clutch pack into the

cylinder. Observe the alignment of the wave

washer to the hole in the cylinder.

25. Install the C2 clutch plates in the cylinder in the

following sequence:

•

Friction disc

•

Steel plate

•

Friction disc

•

Steel plate

•

Steel plate (0574-000013, `014, `015, `016, `019,

`022), or Friction disc (0574-000012 & `017)

•

Steel plate (selective)

•

Friction disc

•

Steel plate (selective)

•

Friction disc

21. Holding the cylinder horizontal, install the sleeve

and clutch plate assembly into the cylinder, with

the crest of one wave of the washer in line with

one of the holes in the outside of the cylinder,

until the sleeve contacts the C2 wave washer.

22. Check the C4 clutch pack clearance using 0555-

336260 clutch pack clearance kit.

Notice: With the C2 wave spring compressed, and

the clutch Pack supporting a 2 kg weight, the

dimension from the underside of the C2 pressure plate

to the selective steel is to be between 1.4 - 1.8 mm. If

the clutch is to be gauged from the top of the pressure

plate, then the dimension is to be the actual thickness

of the pressure plate plus 1.4 - 1.8 mm.

23. Use selective plates to achieve the correct

specification. If new friction plates are being

fitted, remove the clutch pack and soak the friction

plates in ATF for a minimum of 5 minutes prior to

reassembly.

Notice: The clutch pack clearance must be taken

before the elements are soaked in ATF.

KAA5A0J0

KAA5A0K0

KAA5A0L0