SsangYong Rexton. Service manual - part 553

AUTOMATIC TRANSMISSION 5A-187

SSANGYONG Y200

KAA5A0TA

KAA5A0U0

KAA5A0V0

KAA5A0W0

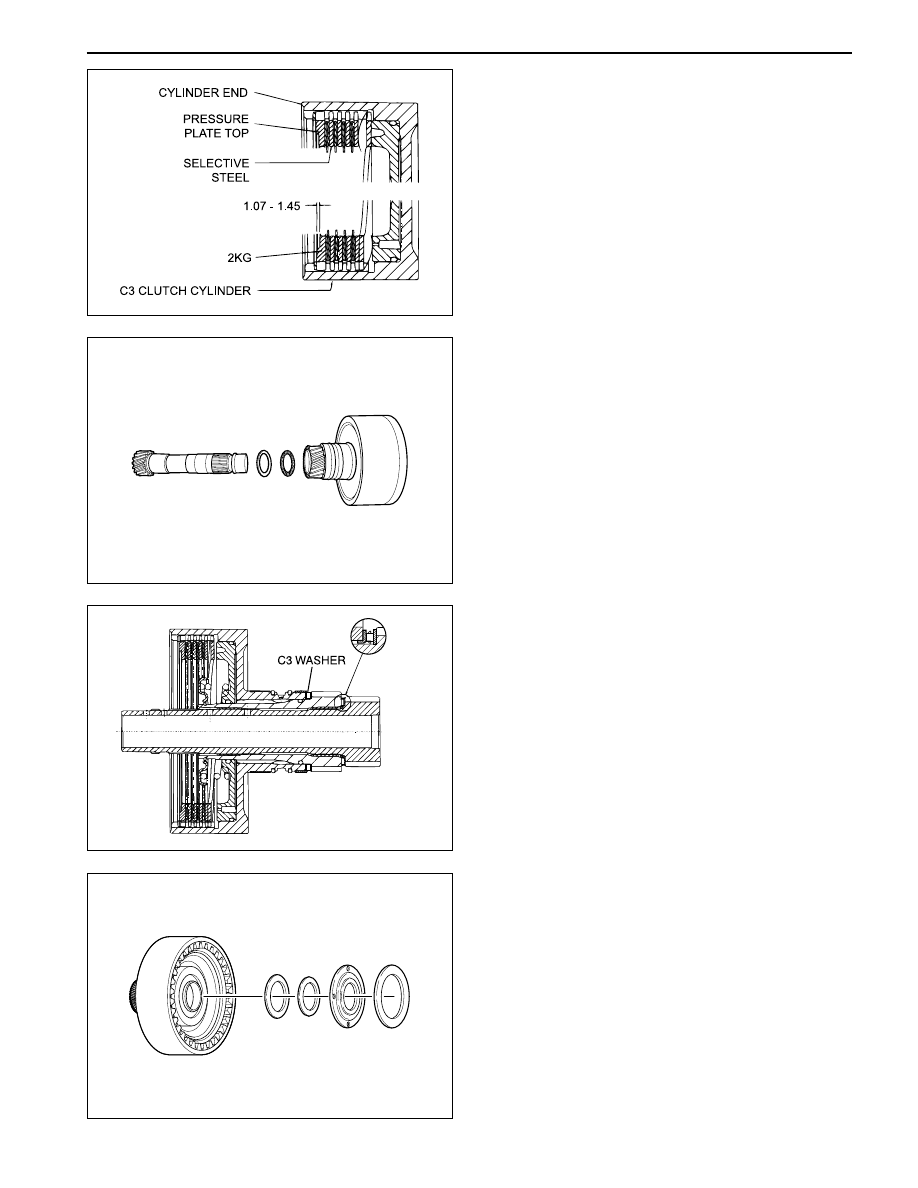

Notice: With the clutch pack supporting a weight

of 2kg, the clearance between the snap ring and

the top of the pressure plate is to be between 1.07

- 1.45 mm.

15. If new friction plates are being fitted, remove the

clutch pack and soak the friction elements in auto-

matic transmission fluid for a minimum of five min-

utes prior to reassembly.

Notice: The clutch pack clearance must be taken

before the elements are soaked in automatic

transmission fluid.

Forward Sun Gear and C3 Clutch Pack

Assembly

1. Fit the No.7 needle bearing assembly over the for-

ward sun gear, ensuring that the thrust washer is

between the bearing and the sun gear.

2. Lubricate the lipped thrust plate with petroleum

jelly and fit the thrust plate onto the reverse sun

gear.

3. Align and fit the C3 clutch assembly over the for-

ward sun gear.

4. Lubricate the No.6 needle bearing with petroleum

jelly and fit it to the thrust plate. Ensure the lugs

on the outside diameter of the bearing fit in the

thrust plate counterbore.

5. Align and fit the plastic thrust washer to the thrust

plate with petroleum jelly.

6. Install the assembly over the forward sun gear

shaft against the No. 6 needle bearing.

7. Place the assembly to one side.