SsangYong Rexton. Service manual - part 550

AUTOMATIC TRANSMISSION 5A-175

SSANGYONG Y200

KAA5A920

KAA5A600

KAA5A930

KAA5A580

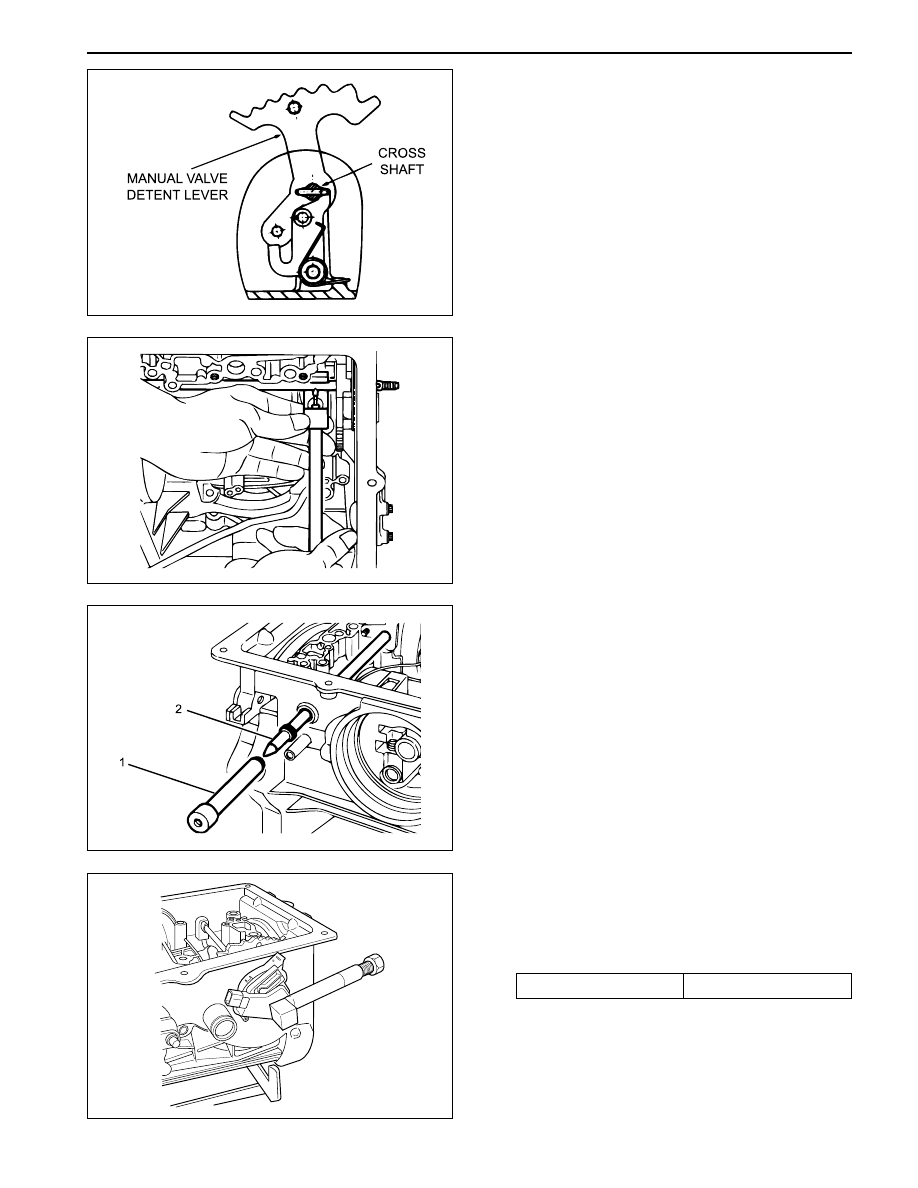

11. Poition the manual valve detent lever, aligning it

with the cross-shaft bore in the case.

12. Push the shaft through the detent lever until it starts

in the detent lever side of the case.

16. Install the new cross shaft seals using cross shaft

seal installer 0555-336262 (1) and cross shaft

bullet 0555-336263 (2).

17. Install the inhibitor switch on the case. Torque the

bolts as per specifications. Press the pin into the

shaft until the tool bottoms using cross shaft pin

installer/ remover (inhibitor switch) 0555-336265.

Installation Notice

18. Thoroughly check the terminal wiring loom for

condition and continuity.

Tightening Torque

4-6 N•m (35-53 lb-in)

13. Install the detent lever drive pin in the shaft using

cross shaft pin remover/installer (detent lever)

0555-336258 with the adaptor over the pin.

14. Press the pin into the shaft until the tool bottoms.

15. Remove the tool and fit the spring retaining circlip

to the shaft.