SsangYong Rexton. Service manual - part 446

SSANGYONG Y200

1F3-4 DIESEL ENGINE CONTROLS

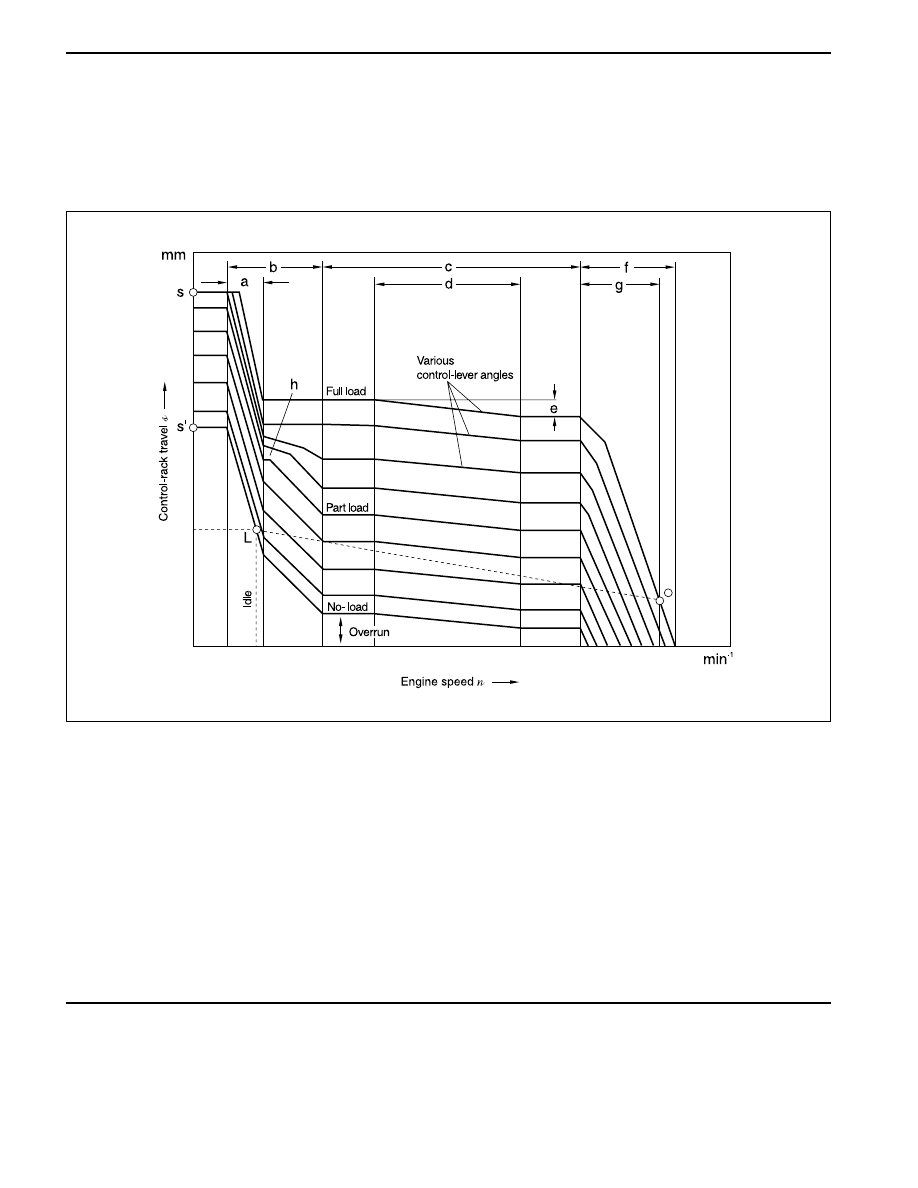

a Idle Range (Working Range of the Idle Spring)

b Extended Idle Range at No-Load and Minimum

Part Load (Working Range of the Idle Spring

and the Auxiliary Idle Spring)

c Uncontrolled Range

d Torque-Control Range (Working Range of the

Torque-Control Spring)

e Torque-Control Travel

f Speed-Regulation Range (Working Range of the

Governor Spring)

g Full-Load Speed Regulation to the High Idle

Speed

h Start of the Auxiliary Idle-Spring Shutoff

GOVERNOR

RSF Minimum-maximum-speed governor

The RSF mechanical governor was developed

specifically as a minimum-maximum-speed governor.

It is suitable for use in those on-road vehicles

(passenger cars and commercial vehicles) in which

YAD1FAC0

S Start Setting With Accelerator Pedal fully

Depressed (Cold-Start)

S ’ Start Setting With Accelerator Pedal Released

(Hot/ Warm Start)

L Low-Idle-Speed Setting

O High-Idle-Speed Setting

n

1u

Low Idle Speed

n

1o

High Idle Speed

n

vo

Maximum Full-Load Speed

n

1

Speed at Start of Torque Control

n

2

Speed at End of Torque Control

control requirements are restricted to low idle and high

idle (maximum) speeds.control requirements are

restricted to low idle and high idle (maximum) speeds.

In the uncontrolled range between these two speed,

the driver uses the accelerator pedal to directly adjust

the setting of the injection-pump control rack so that

the engine develops the right torque.