SsangYong Rexton. Service manual - part 447

SSANGYONG Y200

1F3-8 DIESEL ENGINE CONTROLS

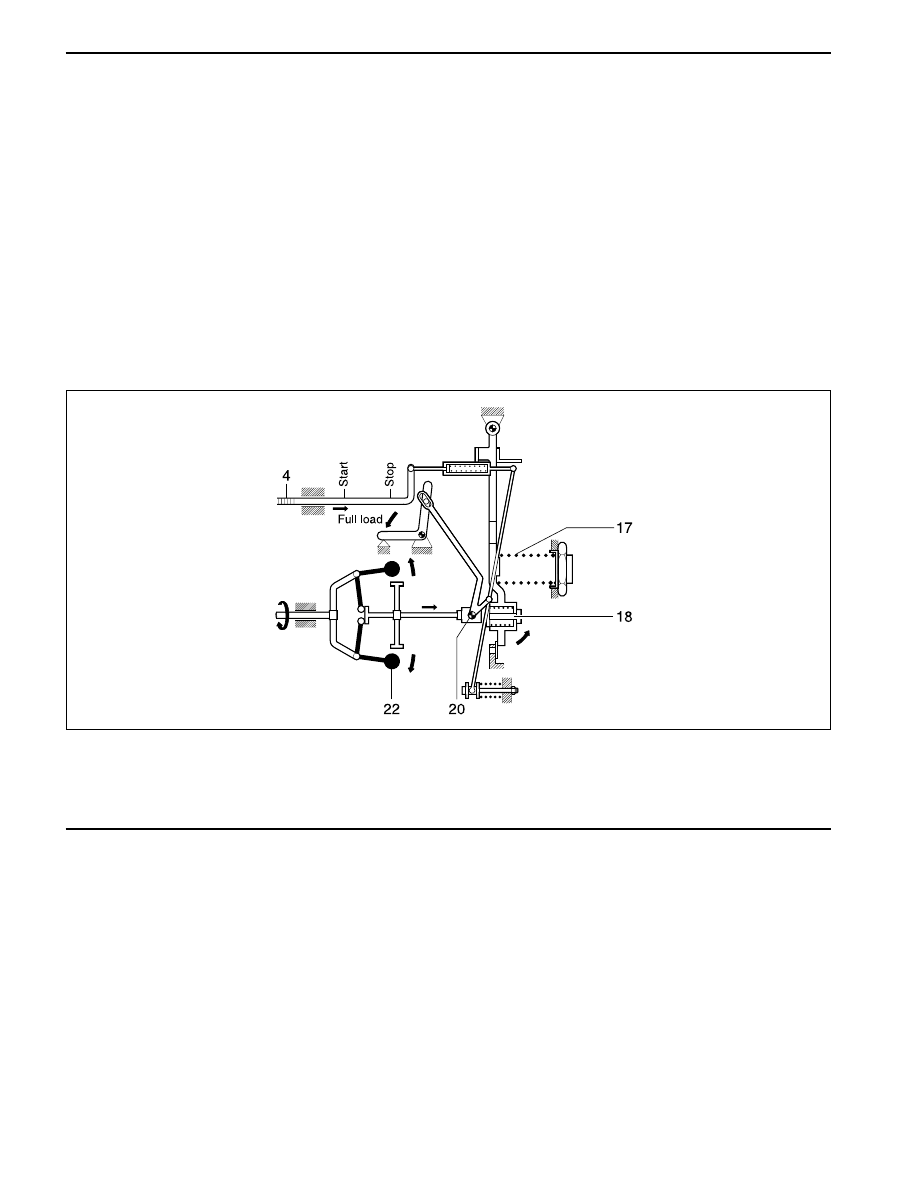

YAD1FAG0

Torque control

If torque control is fitted, full-load delivery quantity is

reduced when a given speed n

1

is exceeded, because

centrifugal force acting on sliding sleeve (20) exceeds

the force of the torque-control spring fitted in spring

retainer (18). The torque-control spring yields to this

force. As a result, if speed increases further, control

rack (4) shifts by the torque-control travel distance.

Torque control ends at speed n

2

.

Instead of positive torque control, the RDF governor

can have negative torque control. Here the control-rack

setting is controlled by a spring combination.

High idle (maximum) speed

With the accelerator pedal pressed to the floor, the

full-load quantity is injected until the maximum full-

4 Control Rack

17 Governor Spring

18 Spring Retainer (Torque Control)

Full-load setting

(only the components concerned in the governing process are shown)

20 Governor Sliding Sleeve

22 Flyweight

load speed n

vo

is reached. If engine speed increases

beyond full-load speed, the force exerted by the

flyweights (22) suffices to overcome the force of

governor spring (17) and full-load-speed regulation

starts.

Engine speed increases slightly, and rack travel is

reduced due to the rack being moved towards stop

(shutoff) and the delivery quantity decreases.

Breakaway depends upon governor spring pretension.

The engine adjusts to high idle (maximum) speed n

10

when all load is removed.

When driving downhill with the accelerator released,

the vehicle drives the engine (overrun) and accelerates

it.

No fuel is injected during this operating mode (overrun

fuel shutoff).