SsangYong Rexton. Service manual - part 444

SSANGYONG Y200

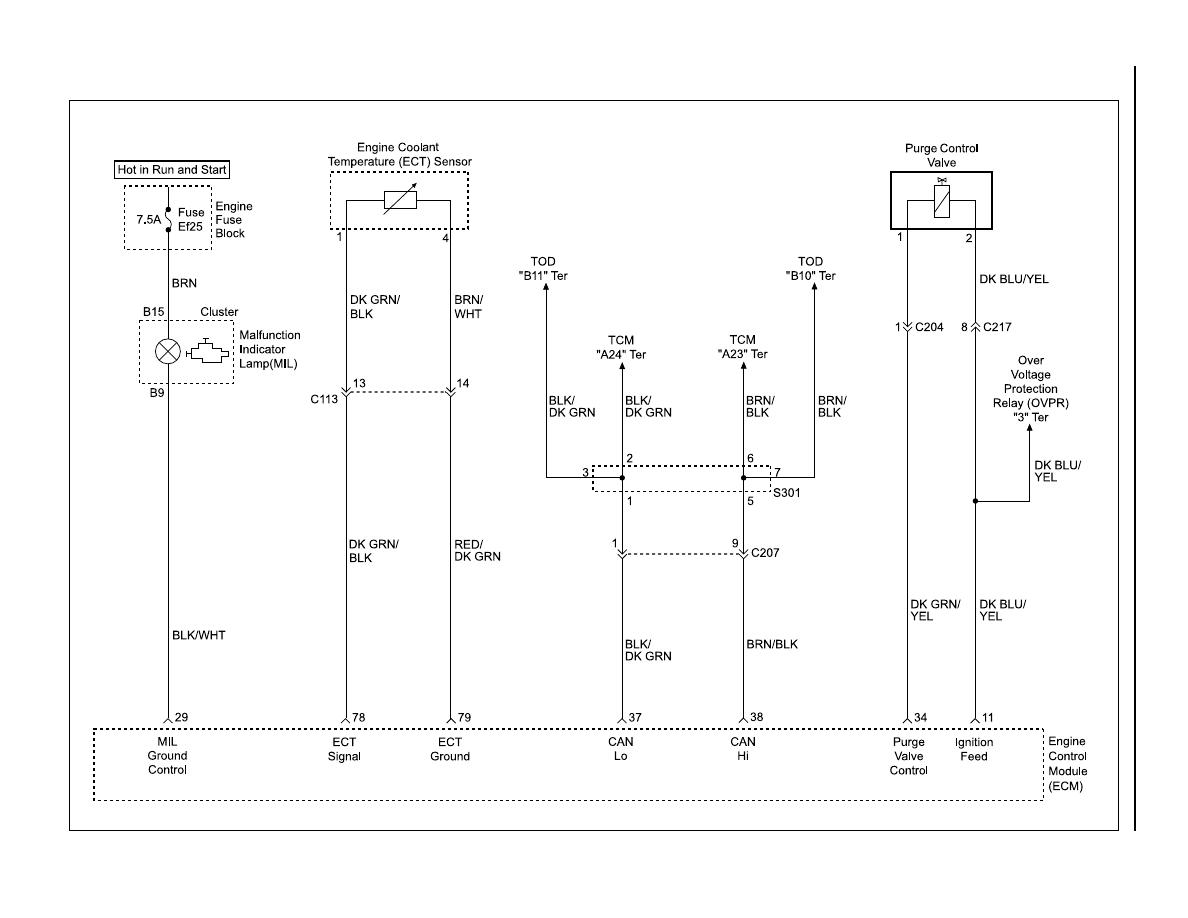

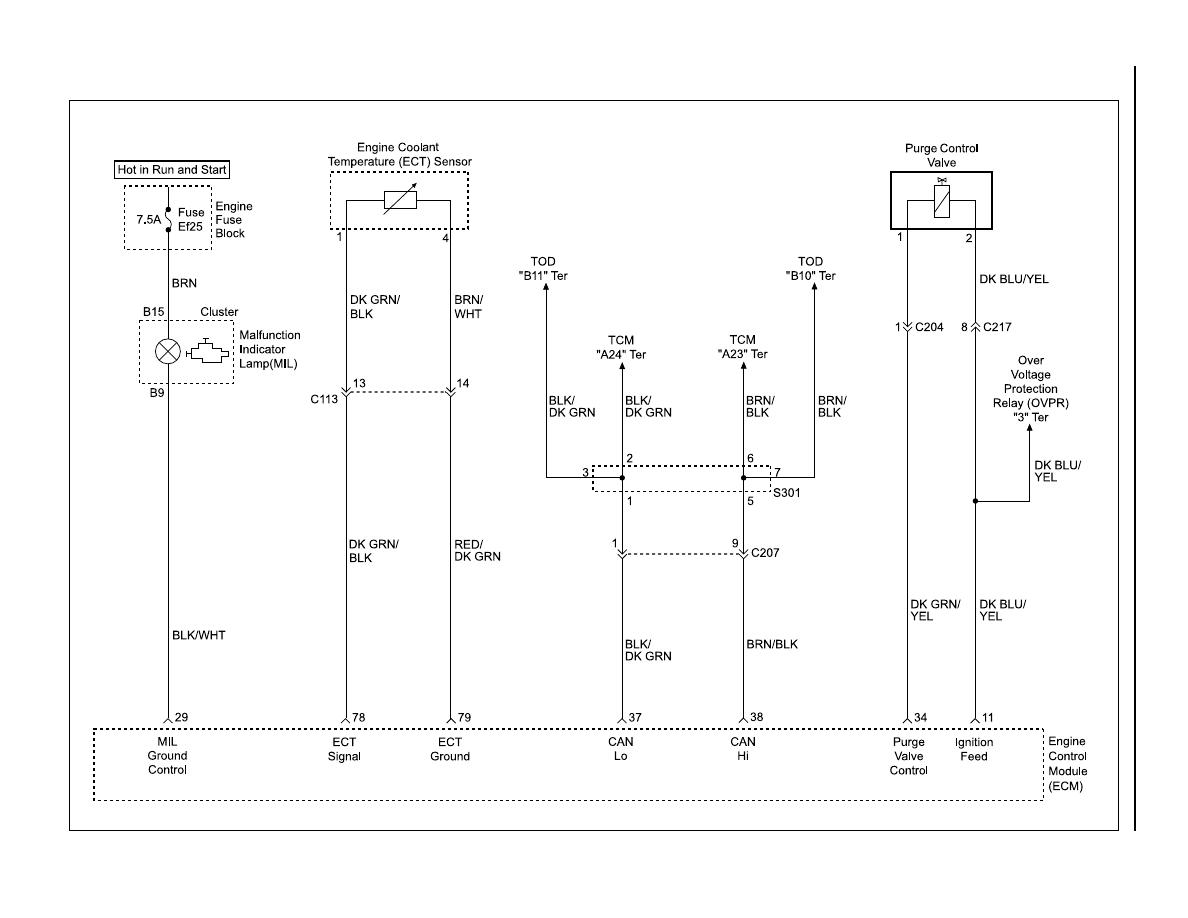

1F2-102 M161 ENGINE CONTROLS

ECM WIRING DIAGRAM (2.3L DOHC - 7 OF 7) (MSE 3.53D)

Y

A

D1F0D0

|

|

|

SSANGYONG Y200 1F2-102 M161 ENGINE CONTROLS ECM WIRING DIAGRAM (2.3L DOHC - 7 OF 7) (MSE 3.53D) Y A D1F0D0 |