SsangYong Rexton. Service manual - part 356

M161 ENGINE MECHANICAL 1B2-107

SSANGYONG Y200

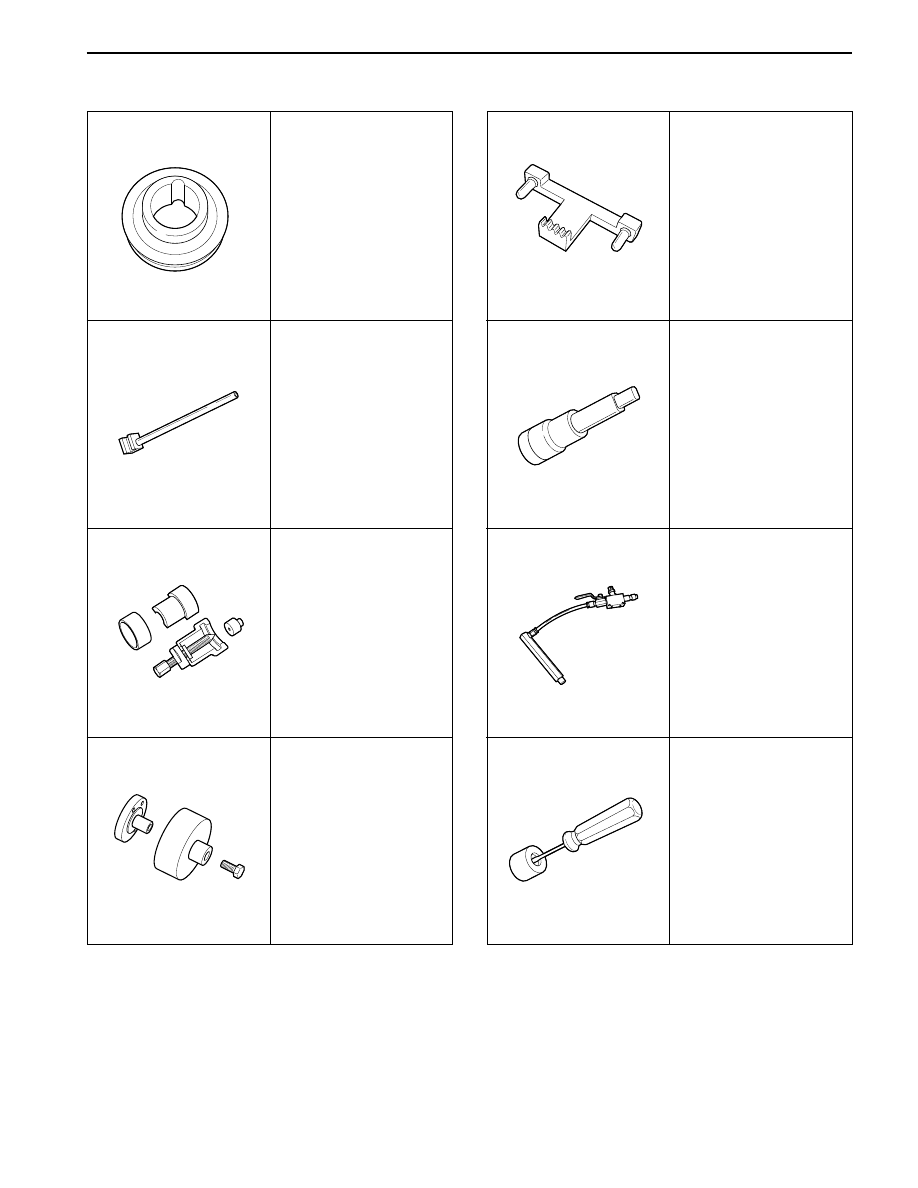

Special Tools Table (Cont’d)

615 589 01 33 00

Crankshaft Sprocket

Puller

601 589 03 43 00

Crankshaft Rear Seal

Installer

601 589 03 14 00

Crankshaft Front Seal

Installer

603 589 00 40 00

Fan Clutch Holder

DW110 - 090

Connecting Hose

DW110 - 100

Valve Tappet Remover

602 589 00 40 00

Engine Lock

617 589 00 10 00

Allen Wrench Socket

YAD1B790

YAD1B720

YAD1B4K0

YAD1B560

YAD1B2M0

YAD1B0Z0

YAD1B730

YAD1B1A0