SsangYong Rexton. Service manual - part 316

M162 ENGINE MECHANICAL 1B1-67

SSANGYONG Y200

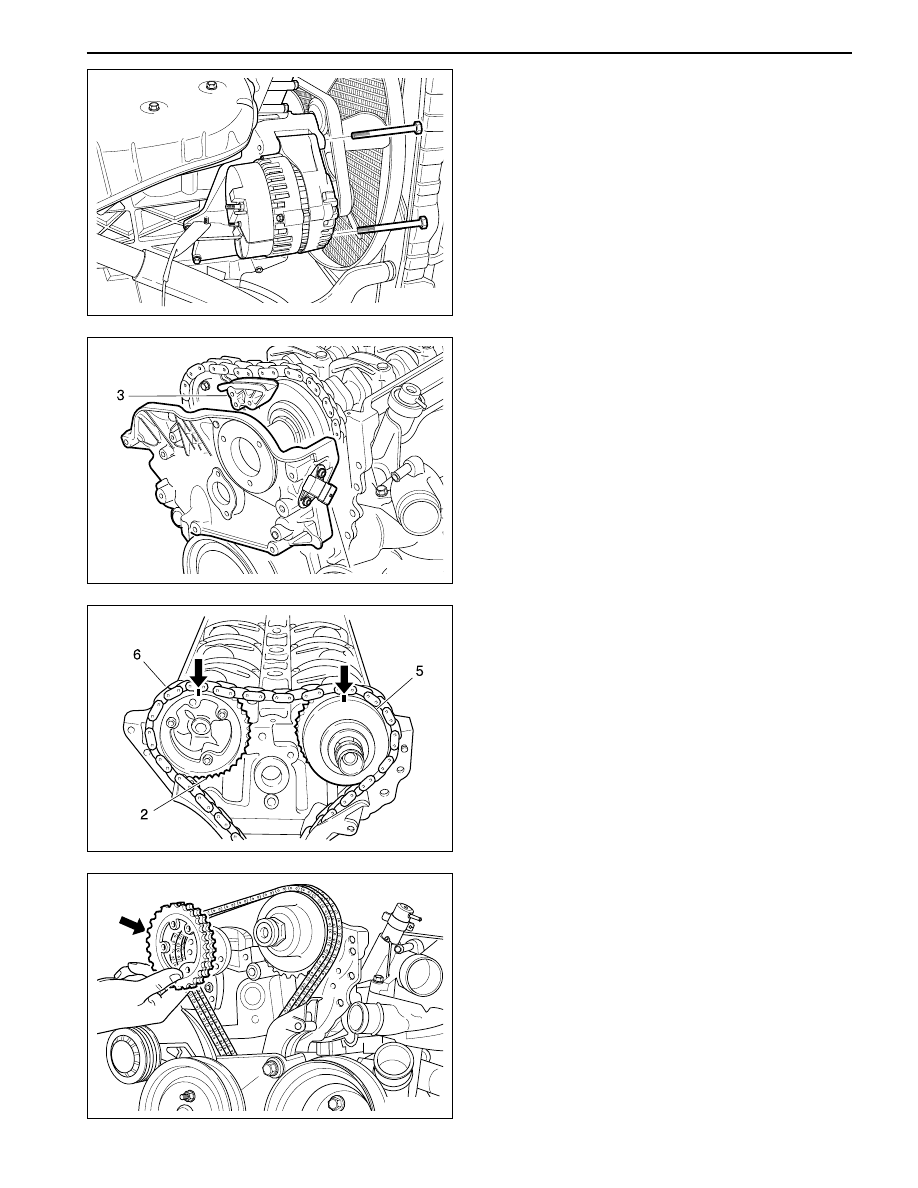

YAD1B240

YAD1B530

YAD1B0L0

YAD1B600

Tools Required

DW 110-120 Holding Pin

Removal Procedure

1. Turn the crankshaft and position the No. 1 cylinder

piston at BTDC 30°.

2. Remove the generator.

3. Remove the chain tensioner. Refer to “Chain

Tensioner” in this section.

4. Remove the cylinder head front cover and the

upper guide rail.

6. Unscrew the exhaust camshaft sprocket bolt and

remove the sprocket.

7. Separate the chain from the intake camshaft

sprocket and put the chain not to be dropped into

timing case.

5. Put the alignment marks (arrows) on the camshaft

sprocket (2, 5) and the timing chain (6).