SsangYong Rexton. Service manual - part 303

M162 ENGINE MECHANICAL 1B1-15

SSANGYONG Y200

Removal & Installation Procedure

1. Remove the poly v-belt.

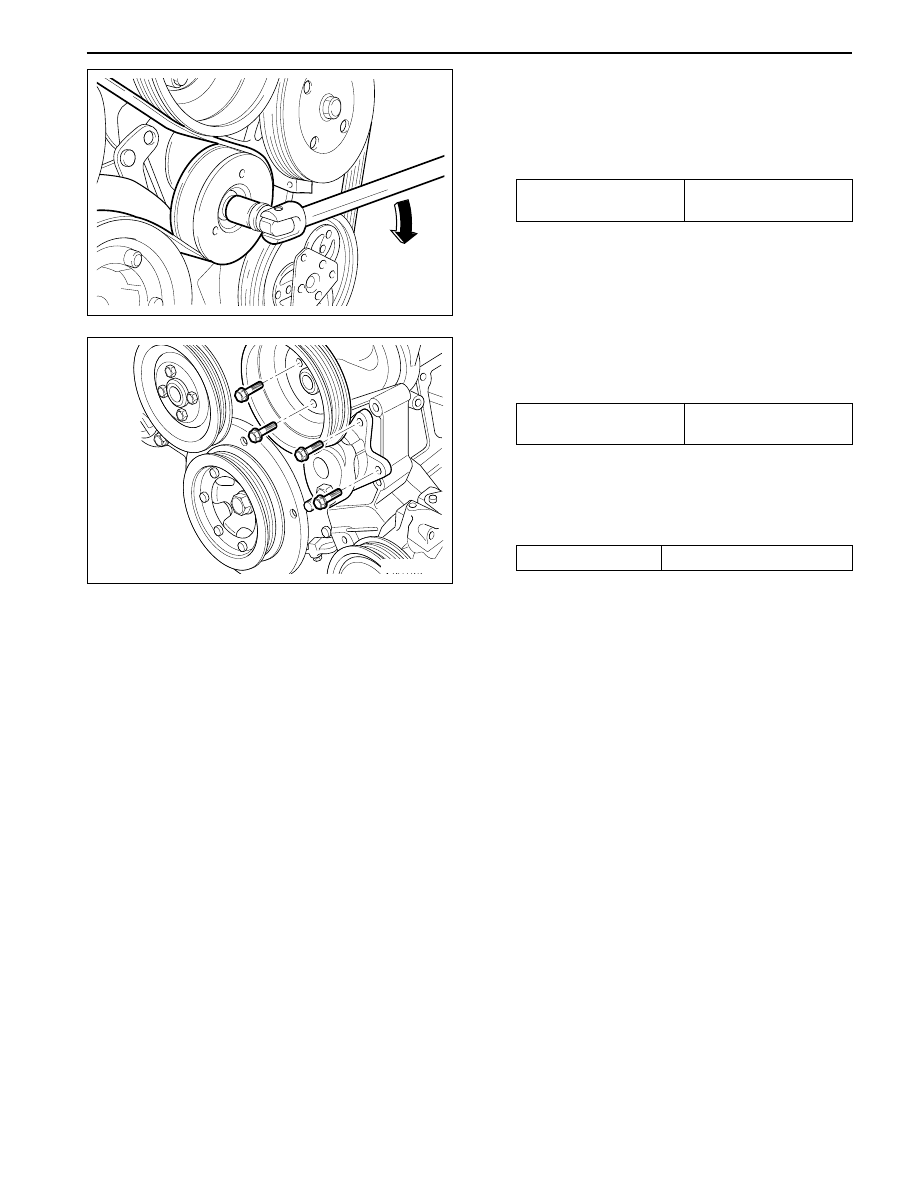

2. Remove the tensioning pulley by turning its

mounting nut counter clockwise as shown in figure.

Installation Notice

3. Remove the bolts and remove the water pump

pulley.

Installation Notice

Tightening Torque

26 - 32 N•m (19 - 24 lb-ft)

Tightening Torque

40.5 - 49.5 N•m

(29.9 - 36.5 lb-ft)

Tightening Torque

22.5 - 27.5 N•m

(16.6 - 20.3 lb-ft)

4. Remove the mounting bolts(M8 x 30, 3 pieces) at

the tensioning device, and remove the tensioning

device.

Installation Notice

5. Installation should follow the removal procedure

in the reverse order.

YAD1B250

YAD1B360