SsangYong Rexton. Service manual - part 54

DI04-29

CHANGED BY

EFFECTIVE DATE

AFFECTED VIN

EXHAUST SYSTEM

DI ENG SM - 2004.4

Y220_04026

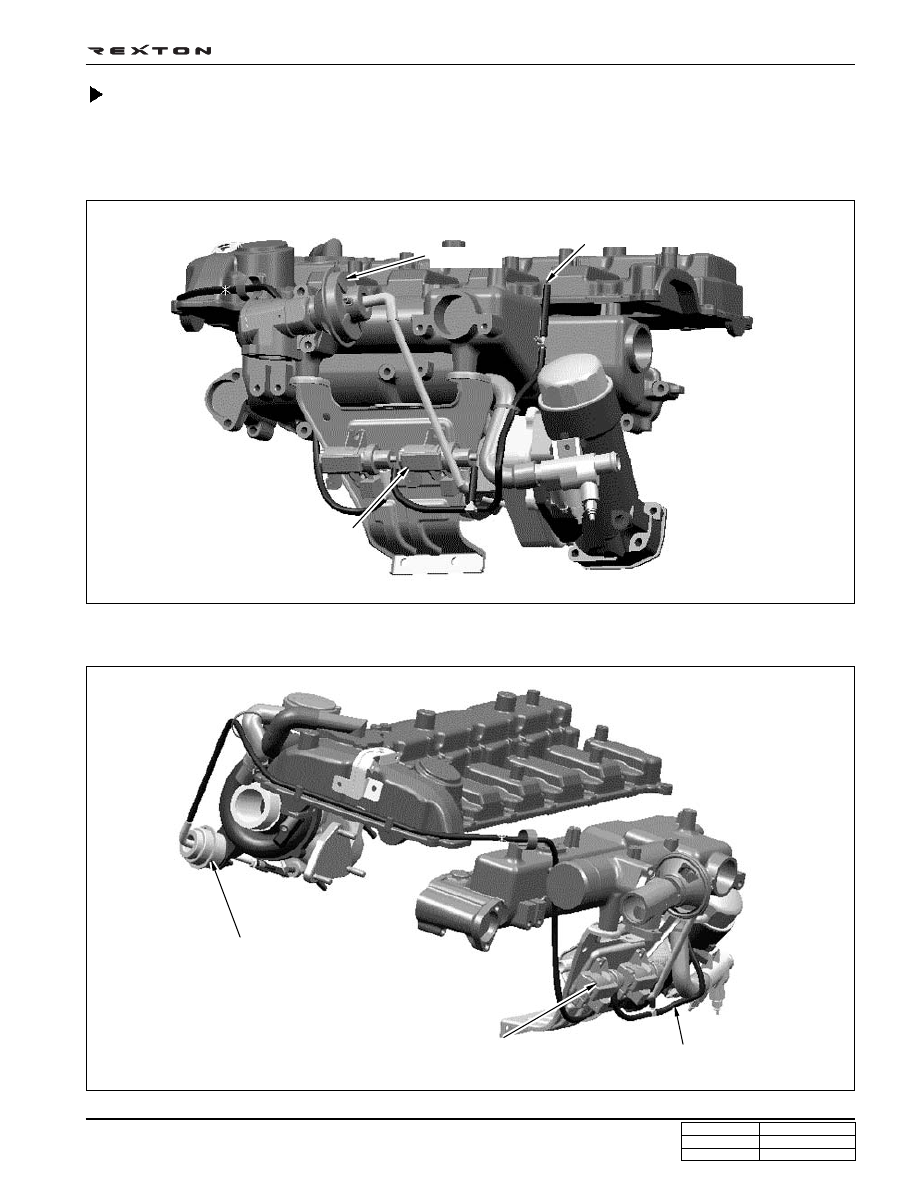

Vacuum Modulator and Vacuum Hose

Below figures illustrate vacuum hoses and related parts of EGR or turbo where wrong or poor connection of vacuum hose

would display condition of engine irregularity and defect diagnostic codes on the scan tool.

Related with EGR valve

Y220_04027

Related with turbo charger actuator

EGR valve

From vacuum pump

Vacuum modulator for

EGR valve control

Turbo charger pressure valve

Vacuum modulator for turbo

charger booster control

From vacuum pump