Nissan Versa Sedan. Instruction - part 887

TM-454

< UNIT REMOVAL AND INSTALLATION >

[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

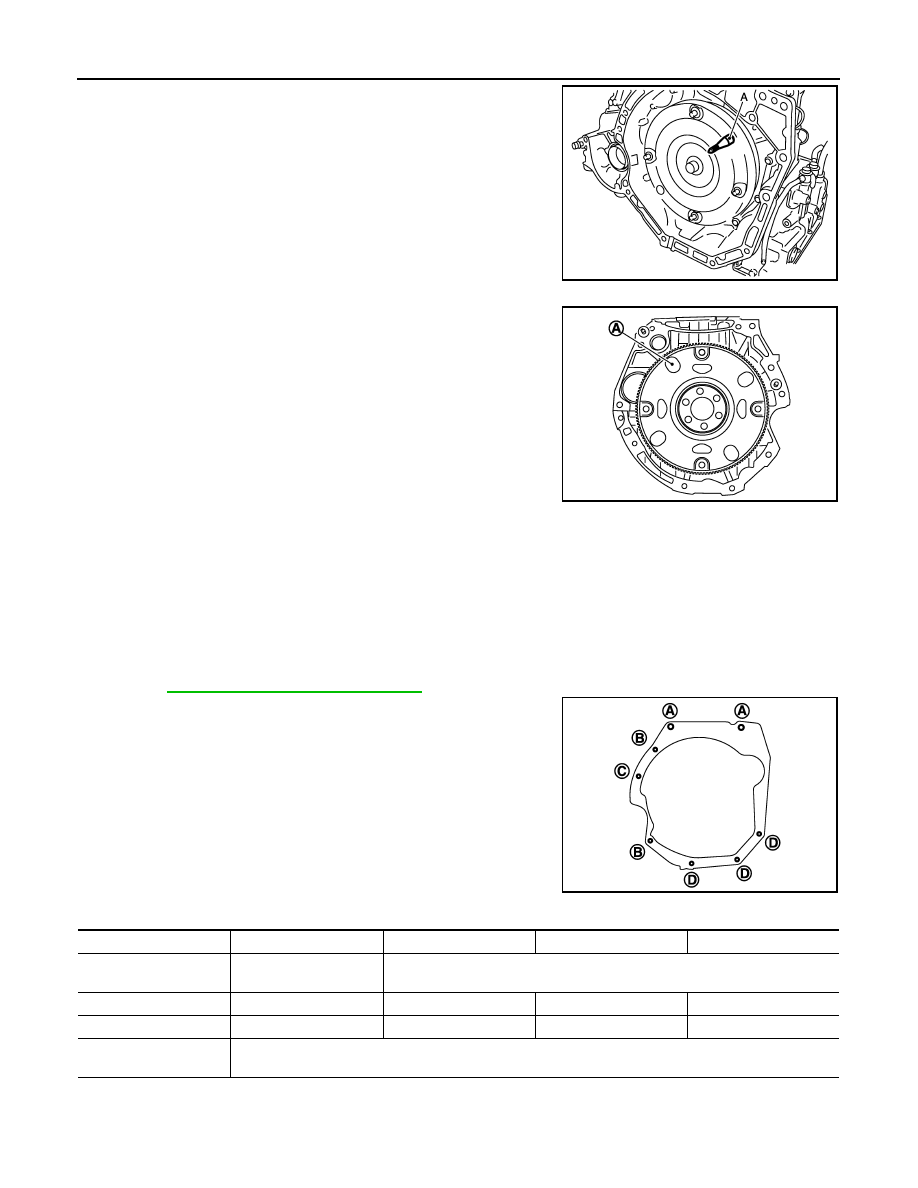

• When using suitable tool (A) for alignment, install it to the align-

ment stud bolt used to align the torque converter to the drive plate.

• Rotate the crankshaft so that the alignment hole (A) of drive plate

aligns with the position of the torque converter alignment stud bolt.

CAUTION:

• Rotate the crankshaft clockwise (as viewed from the front of

the engine).

• Be careful that torque converter stud bolts are aligned to the

drive plate holes. Otherwise the stud bolts contact the drive

plate.

• Insert the alignment stud bolt of torque converter into the align-

ment hole of the drive plate, aligning the drive plate holes with the

torque converter stud bolts.

CAUTION:

Be careful not to strike the drive plate with the torque converter stud bolts.

• When installing the torque converter nuts, temporarily tighten the nuts. Then, after installing the engine and

transaxle assembly bolts tighten the nuts to the specified torque.

CAUTION:

• Rotate the crankshaft clockwise (as viewed from the front of the engine).

• Check the tightening torque for the crankshaft pulley bolts after the bolts fastening the drive plate

and torque converter have been tightened and the crankshaft pulley bolts have been secured.

EM-47, "Removal and Installation"

• Install the transaxle assembly and engine assembly bolts accord-

ing to the following standards.

Inspection and Adjustment

INFOID:0000000009268282

INSPECTION BEFORE INSTALLATION

JPDIA0683ZZ

Tightening torque

: 51 N·m (5.2 kg-m, 38 ft-lb)

JPDIA0684ZZ

JSDIA1839ZZ

Bolt position

A

B

C

D

Direction of insertion

Transaxle assembly

⇒

Engine assembly

Engine assembly

⇒ Transaxle assembly

Quantity

2

2

1

3

Nominal length [mm (in)]

40 (1.57)

44 (1.73)

69 (2.72)

49 (1.93)

Tightening torque

N·m (kg-m, ft-lb)

48.0 (4.9, 35)