Nissan Versa Sedan. Instruction - part 479

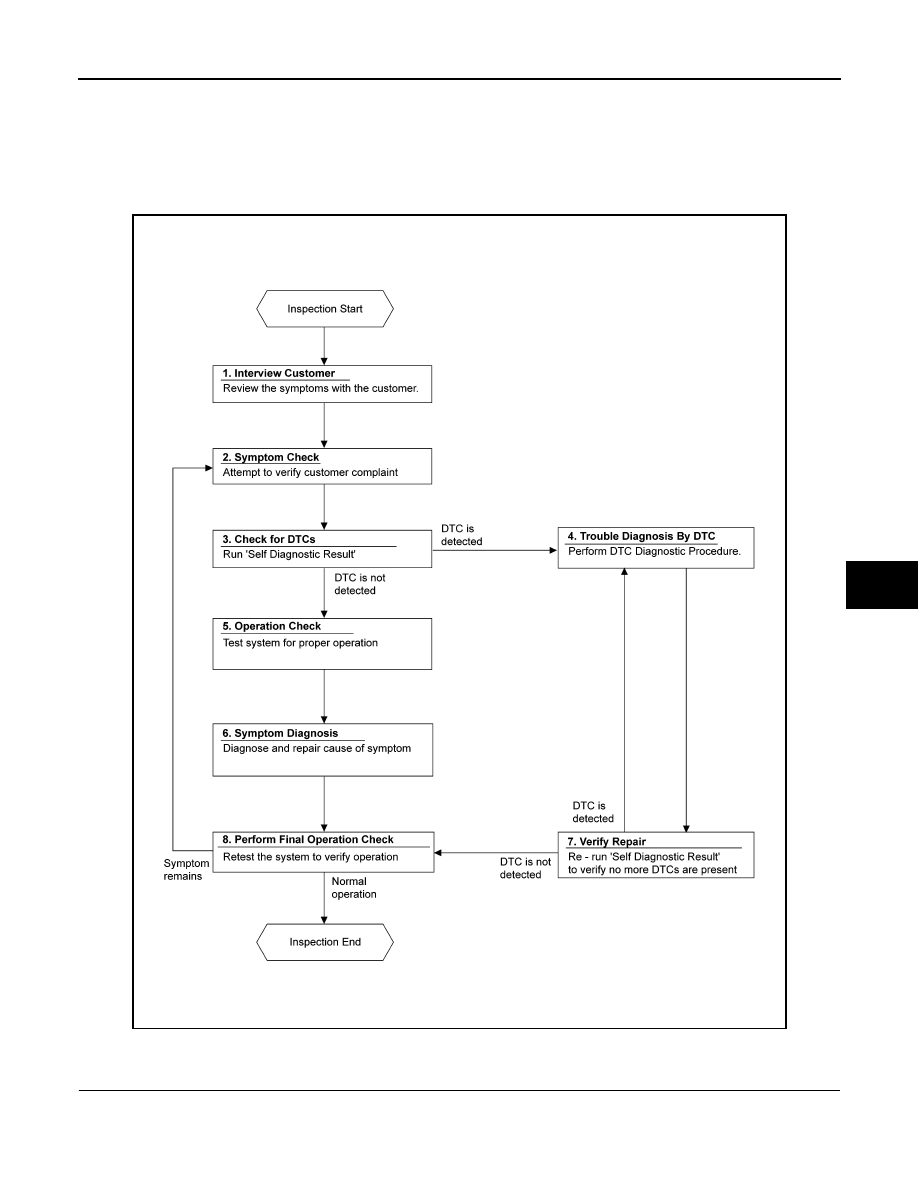

DIAGNOSIS AND REPAIR WORKFLOW

HA-15

< BASIC INSPECTION >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Workflow

INFOID:0000000009269736

OVERALL SEQUENCE

DETAILED FLOW

1.

INTERVIEW CUSTOMER

Interview the customer to obtain as much information as possible about the conditions and environment under

which the malfunction occurred.

ALIIA0440GB