Nissan Versa Sedan. Instruction - part 477

PRECAUTIONS

HA-7

< PRECAUTION >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following:

• When the compressor is removed, store it in the same position as it is when installed on the vehicle.

Doing so will cause oil to enter the low-pressure chamber.

• When connecting pipes, always use a torque wrench and a back-up wrench.

• After disconnecting pipes, immediately plug all openings to prevent entry of dirt and moisture.

• When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for con-

nection.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

• Do not reuse O-rings.

• O-ring must be installed near the dented portion of pipe.

• When replacing the O-ring, be careful not to damage O-ring and pipe.

• Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to pipe correctly.

• After connecting pipe, perform leak test and make sure that there is no leakage from connections.

When the refrigerant leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

Service Equipment

INFOID:0000000009269727

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Do not

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer’s instructions for tester operation and tester maintenance.

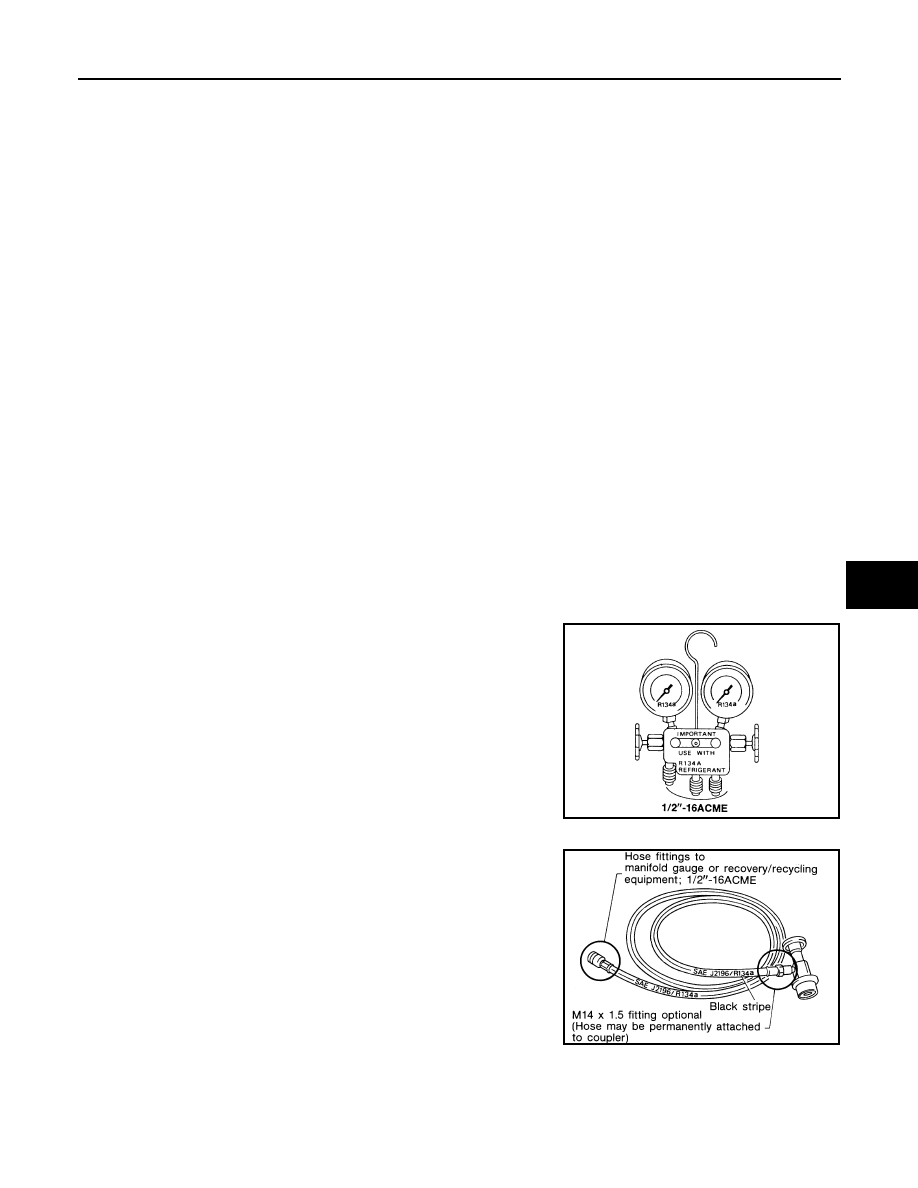

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2

″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must have positive shut-

off devices (either instruction or automatic) near the end of the hoses

opposite to the manifold gauge.

SERVICE COUPLERS

SHA533D

RHA272D