Nissan Versa Sedan. Instruction - part 368

PREPARATION

EM-7

< PREPARATION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Commercial Service Tools

INFOID:0000000009266631

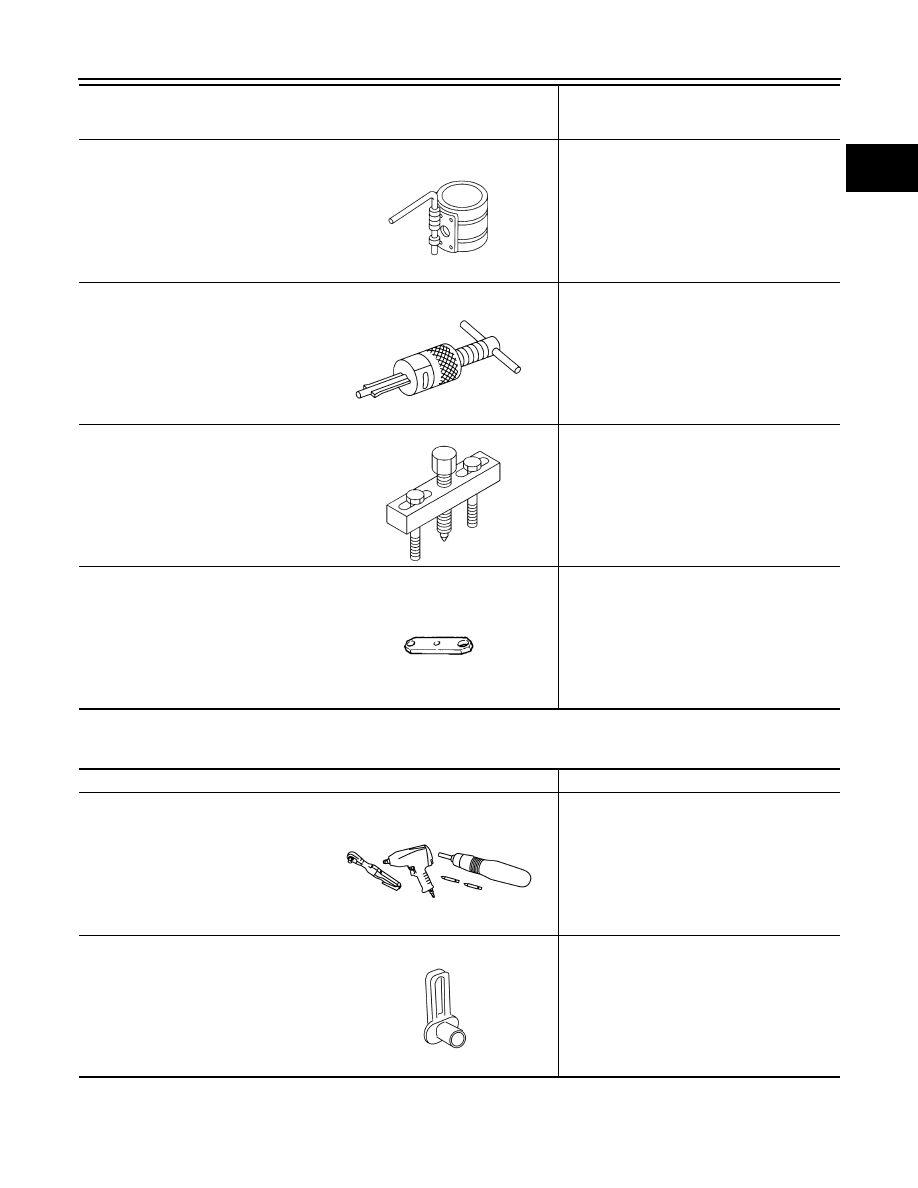

EM03470000

(J-8037)

Piston ring compressor

Installing piston assembly into cylinder bore

ST16610001

(J-23907)

Pulley puller

Removing pilot converter

KV11103000

( — )

Pulley puller

Removing crankshaft pulley

KV11105210

(J-44716)

Stopper plate

Holding drive plate and flywheel static

Tool number

(Kent-Moore No.)

Tool name

Description

S-NT044

S-NT045

NT676

ZZA0009D

Tool name

Description

Power tool

Loosening nuts, screws and bolts

Quick connector release

Removing fuel tube quick connectors in en-

gine room

PIIB1407E

PBIC0198E