Isuzu N-Series. Service manual - part 612

6C-18 ENGINE FUEL

Caution:

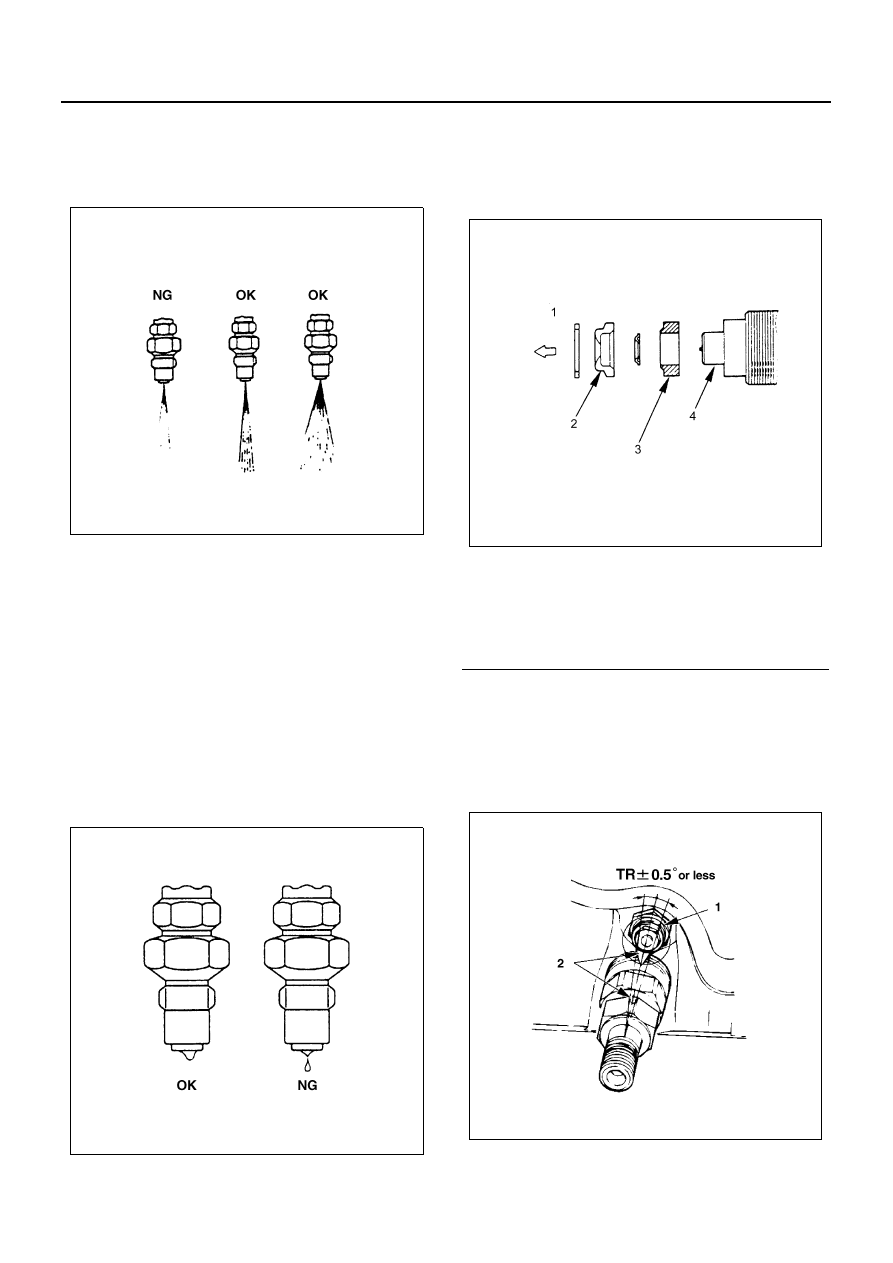

• The spray condition, when judged with a nozzle

tester, is deemed as normal so long as the spray

form is not excessively deformed.

Oil Tight Test (4JG2 Engine)

1. After completion of the adjustment of injection

pressure, wipe off light oil at the tip of the nozzle

with waste.

2. With pressure 1,961 Kpa (20 kg/cm

2

/284 psi) less

than the specified injection pressure applied,

check to see if an oil drop trickles off the tip of the

nozzle within 10 seconds after application of pres-

sure. (There is no problem with the nozzle when oil

gathers at the tip, but does not drop off.)

3. When an oil drop trickles, clean the nozzle thor-

oughly.

Then reassemble it to check for any dropping of oil.

When oil still drops, change it with a new one.

Installation (4JG2 Engine)

Caution:

• Nozzle and assembling should be as illustrated.

• Use new heat shield and new corrugated washer.

1. Injection Nozzle (4JG2 only)

• Lightly tighten the holder nut to suck extent that the

nozzle holder can turn one word and one word.

• Set positioning confirmation drilled hole (

φ2) within

a nozzle turning angle of

±5° against the cylinder

headside positioning boss.

N6A3747E

N6A3748E

Legend

1. Cylinder head side

2. Nozzle heat shield

3. Gasket heat shield

4. Nozzle

N6A3749E

N6A3072E