Isuzu N-Series. Service manual - part 536

Engine Electrical 6D-11

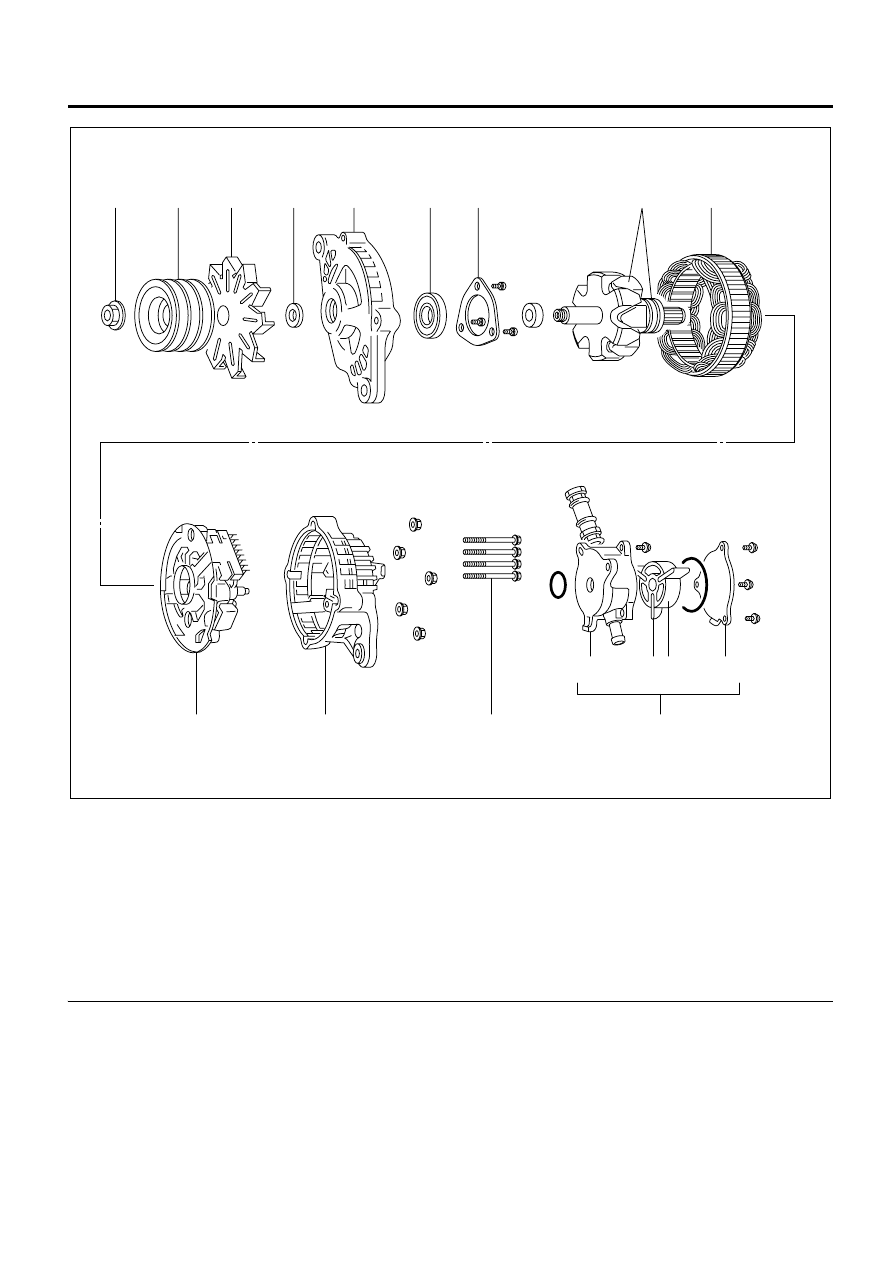

Legend

1. Nut

2. Pulley

3. Fan

4. Spacer

5. Front Cover

6. Front Ball Bearing

7. Bearing Retainer

8. Rotor and Rear Bearing

9. Diode Brush Regulator Assembly

10. Stator

11. Rear Cover

12. Through Bolt

13. Housing

14. Vane

15. Pump Rotor

16. Side Plate

17. Vacuum Pump Assembly

Important:

• Separate the stator and rear cover. Be sure you

identify the proper position of the insulated

washers to prevent improper installation.

Inspection

• All metal parts except the voltage rectifier bridge,

stator, rotor and bearing assemblies in a suitable

solvent.

• Wipe or blow the components dry.

• Brush holder and brushes. The brushes have a

line that indicates their limit. If the brushes are

shorter than 6.5 mm (0.256 in) replace the

brushes.

1

9

11

12

13

14 15

16

2

3

4

5

6

7

8

10

17

N6A6594E