Isuzu N-Series. Service manual - part 537

Engine Electrical 6D-15

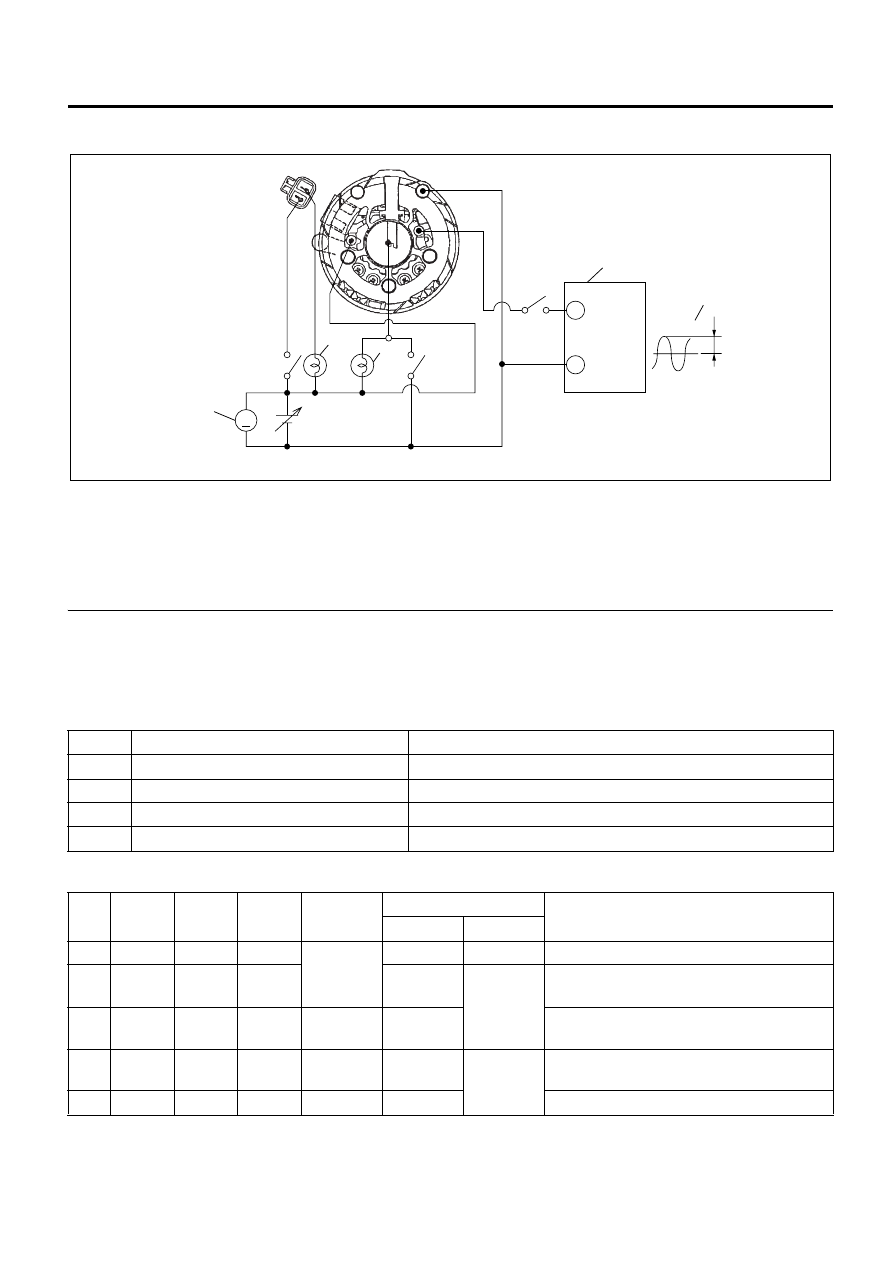

Rectifier Assembly

Legend

1. Voltmeter

2. Switch 1

3. DC Regulated Power Supply

4. Lamp 2

5. Lamp 1

6. Switch 3

7. Switch 2

8. Pulse Generator

9. Output Signal

Test circuit

Refer to the judgment criteria shown in the Table below.

Carefully check Items 1

− 5. If all the items are OK, the

IC regulator is normal.

Circuit components

Judgment criteria

V

+

-

5~30V

1kHz

S

L

B

E

P

2

1

3

4

5

6

7

8

9

N6A6604E

1

DC regulated power supply

0

− 30 volts variable with output of 1 ampere or more

2

Lamps (2)

24 volts, 1.8 watts

3

Switches (3)

-----

4

DC voltmeter

0

− 60 volts, 0.5 grade

5

Pulse generator (Oscillator)

5

− 30 volts output at a frequency of 1kHz

No.

Switch

1

Switch

2

Switch

3

Voltmeter

reading

Lamp condition

Remarks

Lamp 1

Lamp 2

1

ON

OFF

OFF

24V

On (dim)

ON

Initial excitation check

2

ON

ON

OFF

On or

flashing

OFF

Full excitation check

3

ON

ON

OFF

32V

Off or

on (dim)

Lamp 1 off or dimly lit when the voltmeter

shows less than 24 volts or 32 volts

4

OFF

ON

OFF

24V

On or

flashing

ON

Stator and brush separation check

5

ON

ON

ON

36V

On

Excess voltage check